Composition, hard polyurethane foam material and refrigerating equipment

A technology of composition and polyether combination, which is applied in the field of materials, can solve the problems of practical application difficulties, foaming materials cannot be stored for a long time, etc., and achieve the effects of improving storage stability, good mold release, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

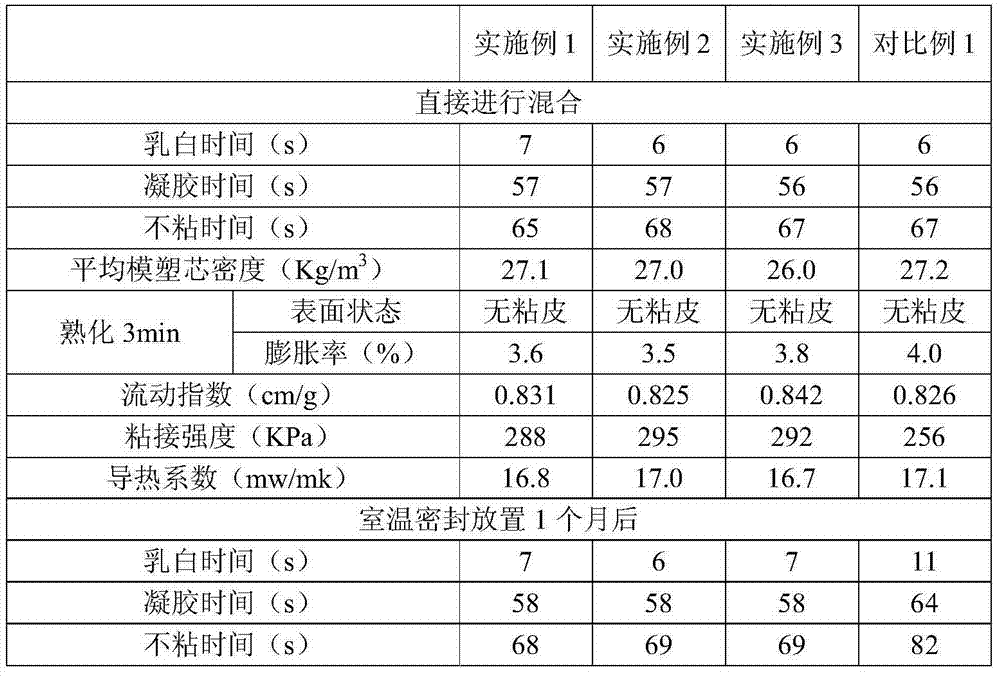

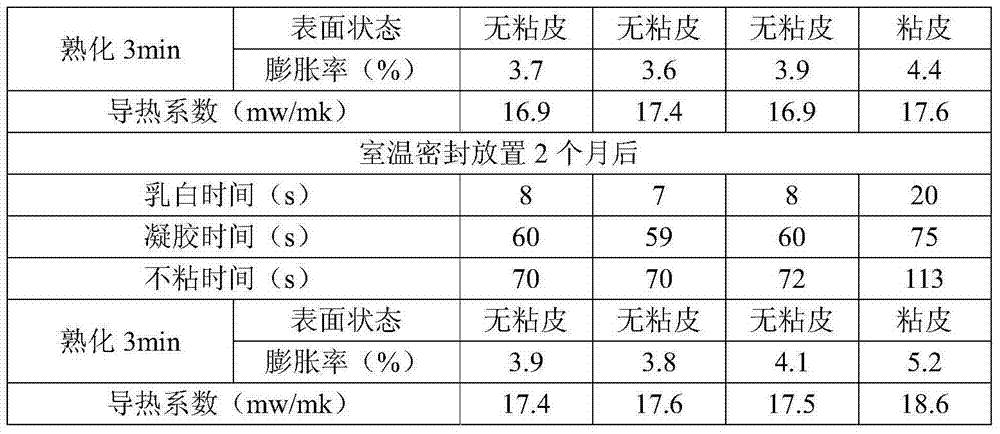

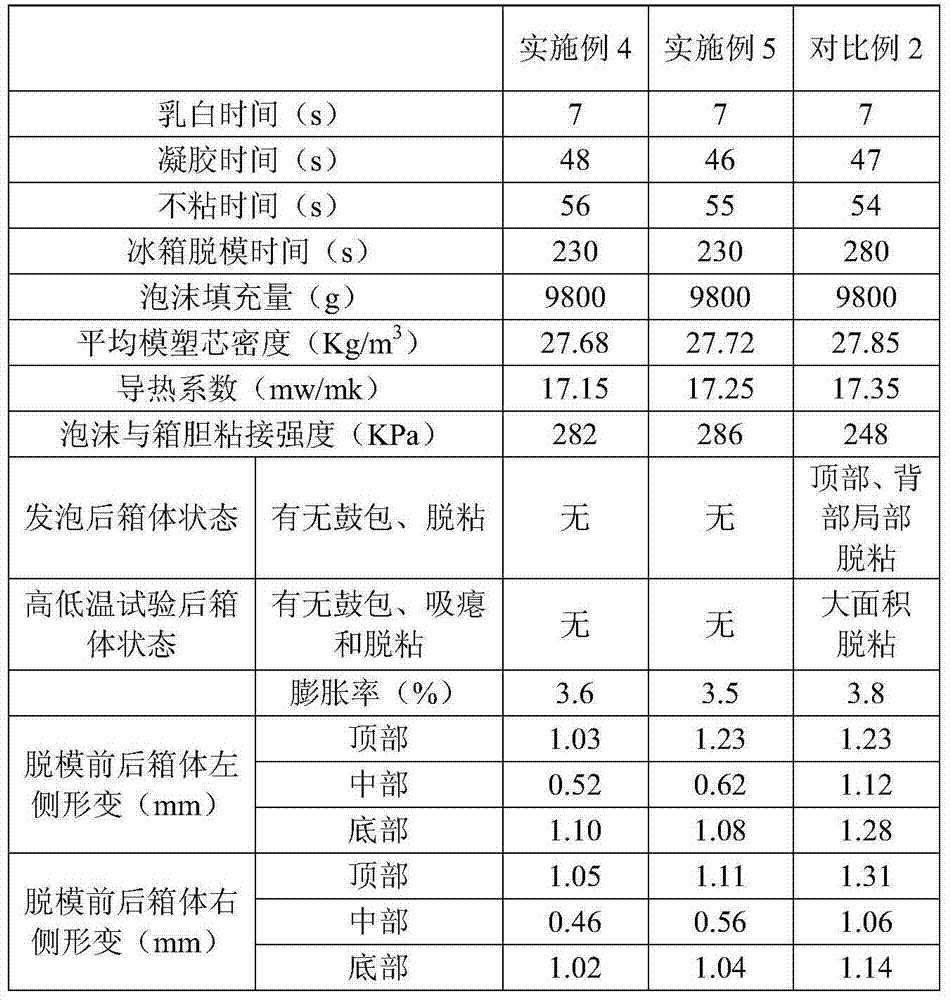

Examples

Embodiment 1

[0040] Raw material formula: 20 parts by weight of polyether polyol A, 20 parts by weight of polyether polyol B, 40 parts by weight of polyether polyol C, 3.3 parts by weight of polyether polyol D, 10 parts by weight of aromatic polyol Ester polyol (viscosity 1200mpa.s, number average molecular weight 550, hydroxyl value 280mgKOH / g, functionality 2.7), 0.5 parts by weight of 1,2-dimethylimidazole, 2.0 parts by weight of N, N-di Methylcyclohexylamine, 0.6 parts by weight of (2-hydroxypropyl) ammonium trimethylformate, 2.0 parts by weight of silicon foam stabilizer (viscosity is 1011mpa.s), 1.5 parts by weight of water, 30 parts by weight of LBA, 137.8 parts by weight of isocyanate (isocyanate index: 1.06).

Embodiment 2

[0042] Raw material formula: 20 parts by weight of polyether polyol A, 20 parts by weight of polyether polyol B, 40 parts by weight of polyether polyol C, 3.6 parts by weight of polyether polyol D, 10 parts by weight of aromatic polyol Ester polyol (viscosity 1200mpa.s, number average molecular weight 550, hydroxyl value 280mgKOH / g, functionality 2.7), 0.8 parts by weight of 1,2-dimethylimidazole, 1.6 parts by weight of N, N-di Methylcyclohexylamine, 0.5 parts by weight of (2-hydroxypropyl) ammonium trimethylformate, 2.0 parts by weight of silicon foam stabilizer (viscosity is 1011mpa.s), 1.5 parts by weight of water, 3 parts by weight of LBA, 9.5 parts by weight of cyclopentane, 12 parts by weight of HFC-245fa, 137.0 parts by weight of isocyanate (isocyanate index: 1.10).

Embodiment 3

[0044]Raw material formula: 20 parts by weight of polyether polyol A, 20 parts by weight of polyether polyol B, 40 parts by weight of polyether polyol C, 3.6 parts by weight of polyether polyol D, 10 parts by weight of aromatic polyol Ester polyol (viscosity 1200mpa.s, number average molecular weight 550, hydroxyl value 280mgKOH / g, functionality 2.7), 1.5 parts by weight of 1,2-dimethylimidazole, 1.0 parts by weight of N,N-di Methylcyclohexylamine, 0.4 parts by weight of (2-hydroxypropyl) ammonium trimethylformate, 2.0 parts by weight of silicon foam stabilizer (viscosity is 1011mpa.s), 1.5 parts by weight of water, 40 parts by weight of LBA, 137.2 parts by weight of isocyanate (isocyanate index: 0.98).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com