Device and method for scraping, replenishing and transferring plate by robot after zinc stripping and zinc-stripping production line

A transfer device and robot technology, applied in the direction of instruments, photography technology, photography auxiliary technology, etc., can solve the problems of wasting manpower and material resources, reducing the production capacity of the zinc stripping production line, etc., and achieve the effects of increasing production capacity, avoiding vacancy, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

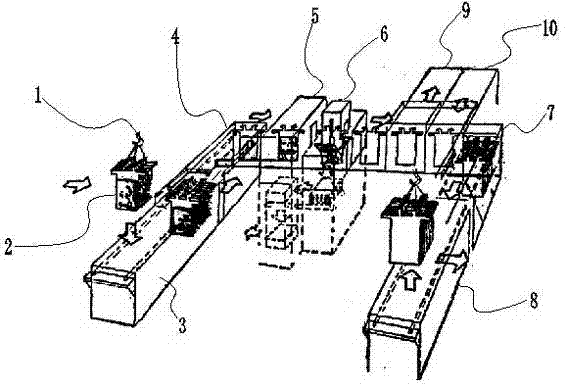

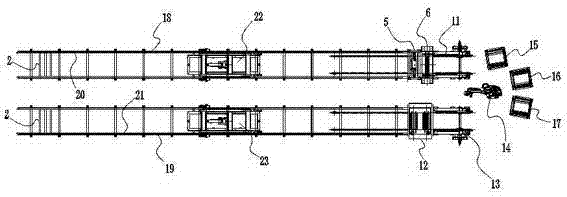

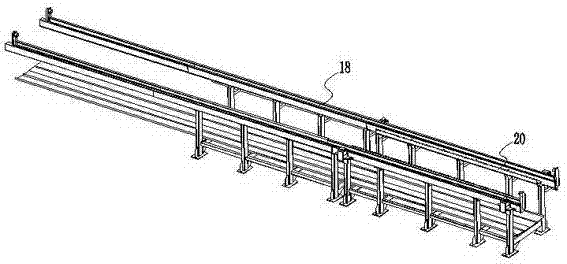

[0039] Embodiment 1: as figure 2 As shown, a robot stripping, patching, and transfer device after zinc stripping includes an input chain delivery device 11 disposed at one end of the cathode plate passing through the stripping device 6 and an output chain located at the cathode plate that has not been washed by the device 12. The industrial robot 14 between one end of the delivery device 13, the reject frame one 15, the reject frame two 16 and the reject frame three 17 arranged on one side of the industrial robot 14; Residual cathode plate, described rejecting frame two 16 is used for rejecting the negative plate that fails to peel off successfully, and described rejecting frame three 17 is used for rejecting the cathode plate that plate body has damage after successfully stripping zinc, by described industrial robot 14 The process is carried out between one end of the input chain conveying device 11 after the cathode plate passes through the stripping device, rejecting frame...

Embodiment 2

[0055] Embodiment 2: as Figure 12 As shown, compared with Embodiment 1, the difference is that the robot stripping, patching, and transfer device after the zinc stripping also includes a patching frame 34 arranged on one side of the industrial robot 14, and the patching frame 34 is placed with a new cathode plate. Qualified cathode plates include the stripped qualified cathode plates on the chain conveying device after passing through the stripping device (that is, the cathode plates with no damage to the plate body after successful stripping) and the new cathode plates on the patch rack; According to the actual situation, the operator can control the industrial robot 14 to fill the qualified cathode plate on the input chain conveying device 11 into one end of the output chain conveying device 13 through the industrial robot 14 or put the The new cathode plate on the patch rack 34 is added to one end of the output chain delivery device 13 through the industrial robot 14 or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com