Iron roughneck makeup-breakout torque testing method

A torque test, iron drill technology, applied in the direction of measuring torque/torsion force, measuring device, torque measurement, etc. during tightening, which can solve the problem of inability to accurately reflect the output torque value of the iron drill, and achieve reasonable design and compatibility. good, spacious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

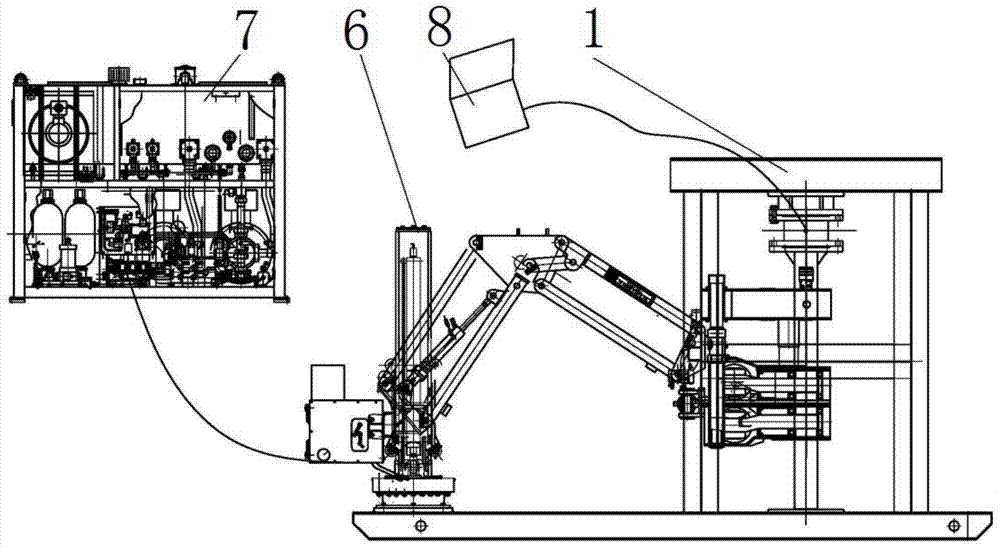

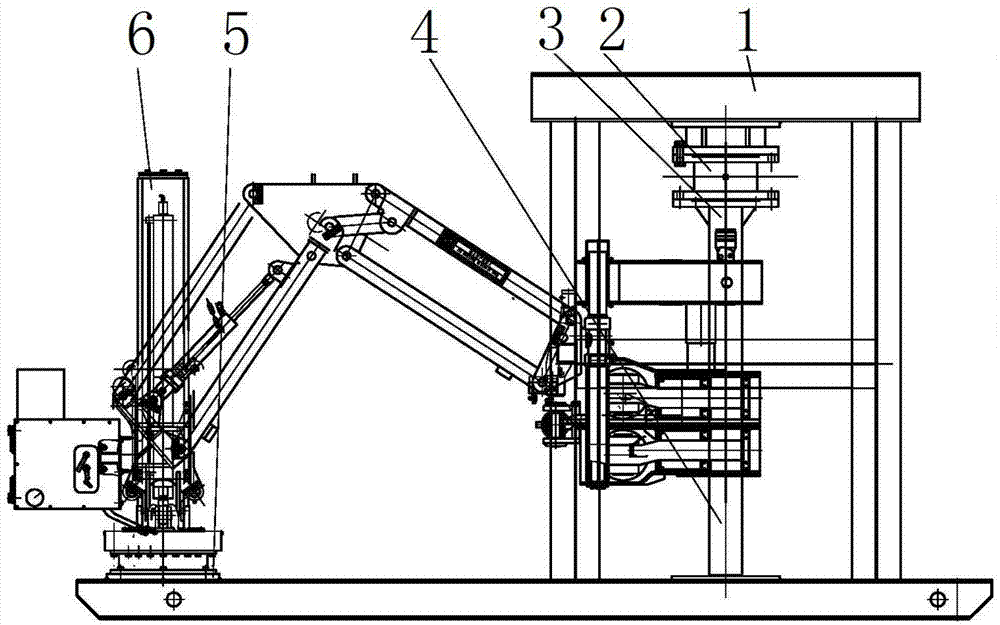

[0020] refer to figure 1 , figure 2 , the structure of the iron driller torque testing device that the inventive method adopts is, test bench 1 and fixed seat 5 are respectively installed on the test bench, iron driller 6 that needs to test is installed on the fixed seat 5, and the test bench 1 A static torque sensor 2 is installed on the lower end of the upper crossbeam, and the static torque sensor 2 is sequentially connected with an upper simulated drilling tool 3 and a lower simulated drilling tool 4, and the lower end of the lower simulated drill The driller 6 is connected with the hydraulic control mechanism 7, and the static torque sensor 2 is connected with the data acquisition mechanism 8 for signals.

[0021] The test bench 1 has a simple structure and a large bearing capacity. The test bench is provided with a fixing seat 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com