Automatic tracking control system of visual laser marker of machine

A technology of laser marking and automatic tracking, which is applied to instruments, scientific instruments, measuring devices, etc., can solve the problems of inability to detect large strain ranges, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

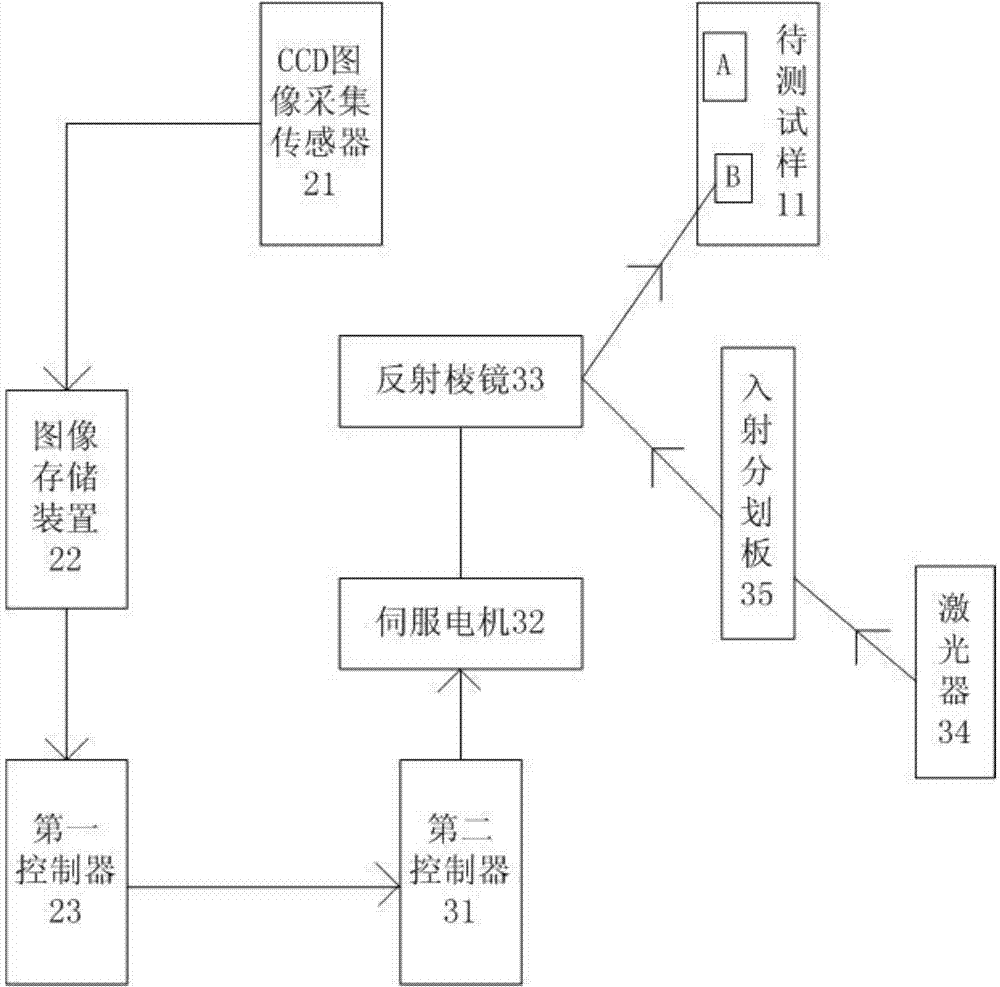

[0014] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a machine vision laser marking automatic tracking control system proposed by the present invention.

[0015] refer to figure 1 , a kind of machine vision laser marking automatic tracking control system that the present invention proposes, comprises test sample 11, image processing system and laser mark automatic tracking system; Image acquisition sensor 21, image storage device 22 and first controller 23, CCD image sensor 21 is connected with image storage device 22, and image storage device 22 is connected with first controller 23; Laser marking automatic tracking system includes second controller 31 , servo motor 32, reflecting prism 33, laser device 34 and incident reticle 35, second controller 31 is connected with servo motor 32, reflecting prism 33 adopts polyhedral cylindrical prism, and polyhedral cylindrical prism adopts 3~8 faces among the present invention cylindrical prism. The mu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap