Method for representing bonding strength of hard film through interfacial stress of elasticoplastic deformation

A technology of elastic-plastic deformation and bonding strength, which is applied in special data processing applications, measuring devices, instruments, etc., to achieve the effect of flexible test conditions and flexible and simple test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

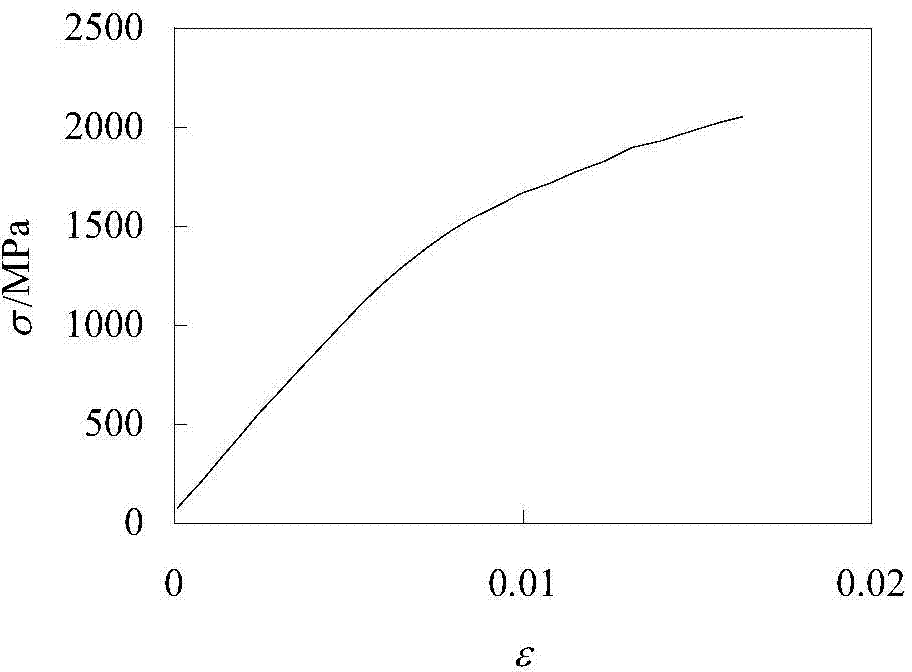

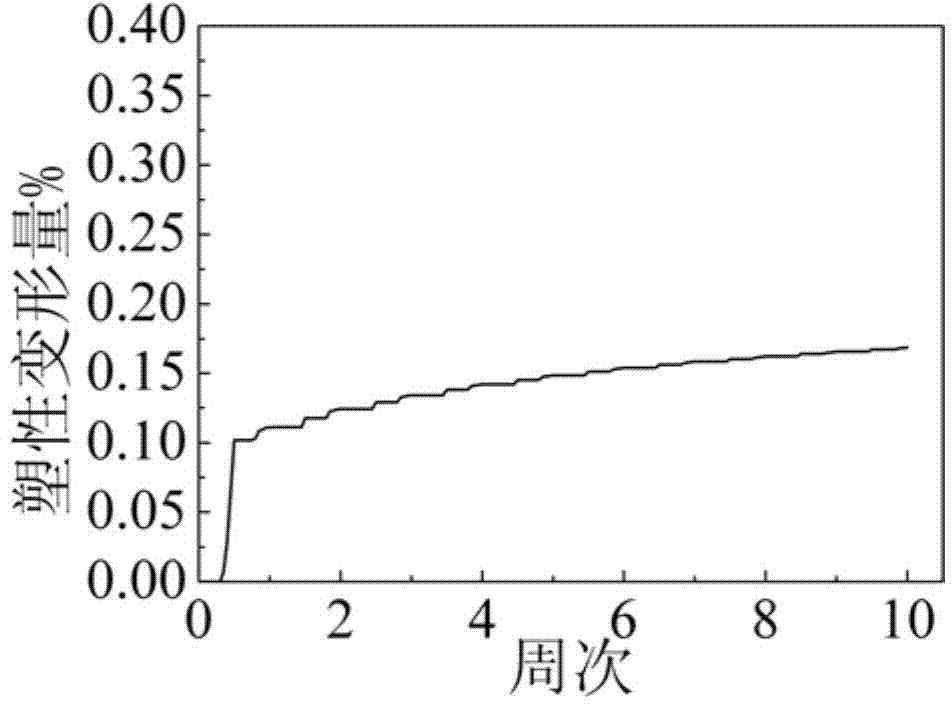

[0031] A kind of method characterizing the bonding strength of hard thin film with the interfacial stress of elastoplastic deformation, comprises the steps:

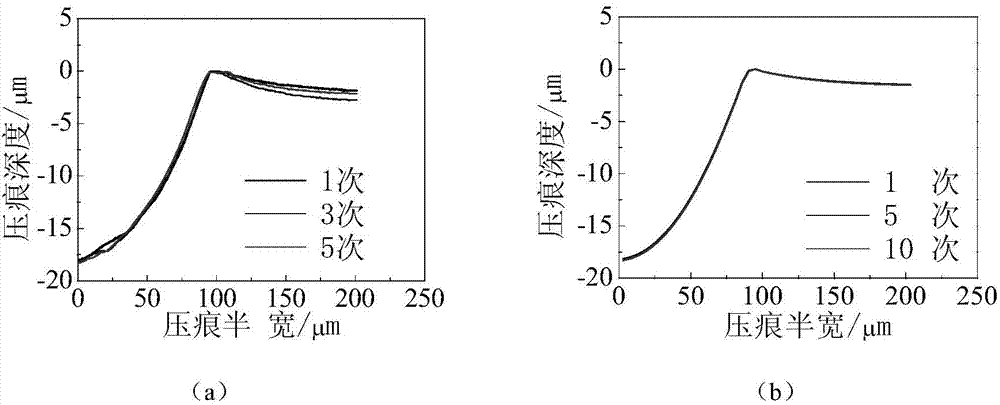

[0032] In the first step, the sample is tested using a cyclic press-in tester

[0033] (1) A sample of MoN film deposited with a thickness of 5.6 μm and a substrate material of GCr15 steel was used for testing. Using a cyclic indentation tester, a diamond spherical indenter with a radius of curvature of 200 μm was used to perform an indentation test on the surface of the sample film under cyclic loading at a fixed peak value and minimum value. The sample film matrix system undergoes elastic-plastic deformation under external loads. The upper limit of the load peak selection in the cyclic indentation test should be less than 90% of the load value when one-time indentation causes peeling off. The minimum load should not be greater than 90% of the peak load. In this embodiment, the peeling load of the film once loaded is ...

Embodiment 2

[0051] The sample was changed to a 2.3 μm CrN thin film, and the operation steps were the same as in Example 1.

[0052] The first step is to use a cyclic indentation testing machine to test the sample with a diamond spherical indenter with a radius of curvature of 200 μm

[0053] (1) Use a cyclic indentation tester to perform an indentation test on the surface of the sample film under cyclic loading with a fixed 60N load peak value. The minimum load values are respectively 15N, 20N, 30N and 40N (the ratio of the minimum load value to the maximum value is 25% respectively. , 33%, 50%, 66%).

[0054] (2) Under the above-mentioned four load ratios, the sample is subjected to a cyclic indentation test and finally the peeling of the film is caused. The observation record shows that the number of cycles that the film peels off under the action of the 25% load ratio is 9.0×10 2 Times; 1.5×10 at 33% 3 times; 1.8×10 at 50% 4 Times; 5.0×10 at 66% 5 Second-rate.

[0055] The seco...

Embodiment 3

[0061] Sample and operating steps are the same as in Example 1.

[0062] The first step is to use a cyclic press-in test machine, and the indenter is Si with a curvature radius of 400 μm 3 N 4 Ceramic spherical indenter, with fixed load peak value and minimum value, carries out indentation test on sample film surface with cyclic loading.

[0063] (1) The peak loads used in this embodiment are 150N and 200N respectively, and the minimum load is selected as 30% of the peak load.

[0064] (2) Under the above two loads, the sample is subjected to a cyclic indentation test and finally causes the peeling of the film. The observation records show that the number of cycles that the film peels off under the peak load of 200N is 1.3×10 5 times; greater than 1.0×10 under 150N 6 Second-rate.

[0065] In the second step, the finite element model is established with embodiment 1, and this embodiment defines Si 3 N 4 The ceramic indenter is elastic: the elastic modulus is 210GPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com