Dynamic fatigue evolution test method for rubber and fiber cord thread bonding

A technology of dynamic fatigue and testing methods, applied in measuring devices, instruments, and mechanical devices, etc., can solve the problems of inability to predict tire life, no reports on data, and dynamic fatigue of bonding, achieving reliable data, broad application prospects, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

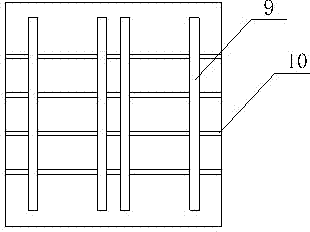

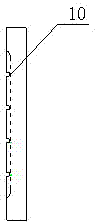

[0040] Preparation of rubber / fiber cord vulcanization specimens: the vulcanization mold used is as figure 1 and figure 2 shown. First place the four strips respectively in the mold cavity shown in the mold with the working side facing up. Then insert the fiber cord into the cord groove, so that the knotted end is stuck in one end of the cord groove, and the other end is naturally tightened by the weight. Then place the other four strips on top of the bottom strip, with the working side facing down. Finally, cover the upper mold and place it on a flat vulcanizing machine for vulcanization.

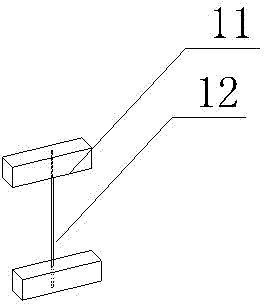

[0041] Rubber / fiber cord fatigue sample preparation: cut the sample with scissors to make an "I"-shaped sample, such as image 3 shown. The sample is buried between two rubber blocks 11 with a length of about 25 mm at both ends of a single fiber cord 12, and the remaining rubber is carefully cut off with scissors, taking care not to damage the fiber cord.

[0042] Dynamic fatigue tes...

Embodiment 1

[0047] Example 1: Dynamic Fatigue Continuous Evolution Strain Control of Rubber and Fiber Cord Bonding

[0048] 1. Preparation before vulcanization:

[0049] Weighing: according to the formula NR 90phr, SBR 10phr, zinc oxide 3phr, stearic acid 2phr, antioxidant RD 2phr, carbon black N330 5phr, carbon black N660 30phr, aromatic oil 500 3phr, binder A 0.8phr, binder RE 0.6phr, DM 1.2phr, TMTD 0.03phr, insoluble sulfur 2.5phr Weigh raw materials;

[0050] Rubber mixing: Add the above raw materials into the internal mixer for rubber mixing, set the initial speed at 60rpm, and the initial temperature at 60°C. First add NR and SBR, and after mixing for 1 minute, add zinc oxide, stearic acid, anti-aging agent RD and adhesive Agent RE, add half of carbon black and aromatic oil when the torque level is about 2 minutes, add the other half of carbon black and aromatic oil at 3.5 minutes, open the top bolt to clean once at 4.5 minutes, and remove glue after 8 minutes. After the rubber m...

Embodiment 2

[0059] Example 2 Rubber and Fiber Cord Bonding Dynamic Fatigue Continuous Evolution Stress Control

[0060] Other steps adopted in the second embodiment are the same as those in the first embodiment, except that the clamps are different and step 4 is different. In step 4, instead of setting the maximum tensile displacement, the maximum tensile stress of the upper and lower clamps is set to 22N by computer for dynamic testing. In the screening data, the displacement value when the tension value is about 22N is plotted against time, and the following can be obtained: Figure 8 curve. The dynamic evolution of bonding over time can also be seen.

[0061] The difference between the clamp and the first embodiment is that the others are the same, except that the rotating adjustment handle 5 includes an elliptical adjusting rod located above the limit plate 6, and a connecting shaft is arranged at the center of one end of the elliptical adjusting rod, and the connecting shaft passes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com