Optical fiber main distribution frame

A general distribution frame, optical fiber technology, applied in optics, light guides, optical components, etc., can solve the problems of inconvenient installation of LED lights, limited space, high processing defect rate, and achieve the effect of satisfying line transformation and transition and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

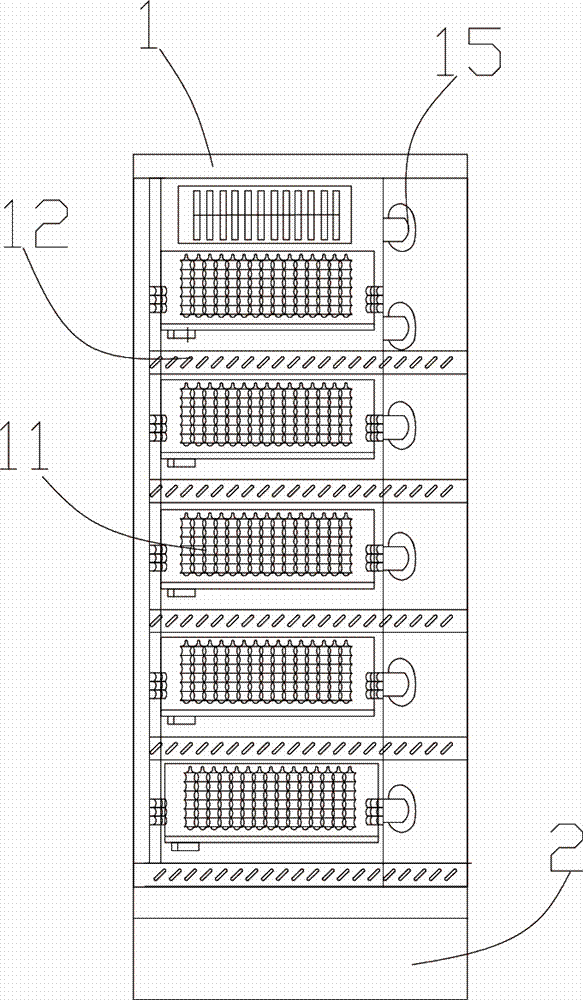

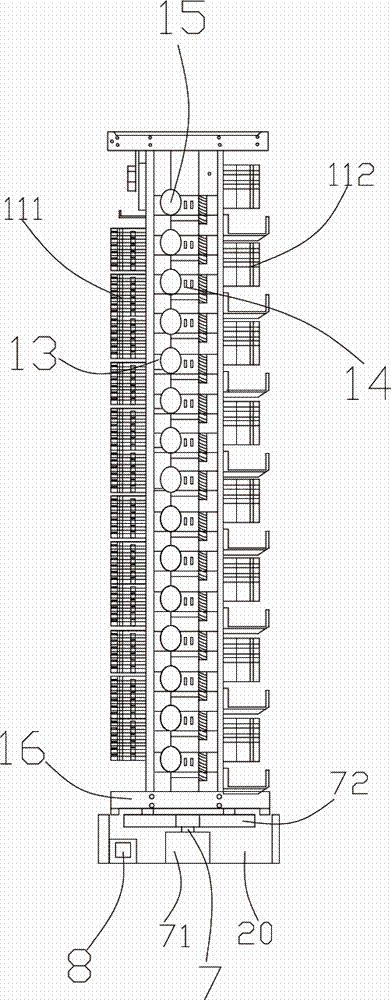

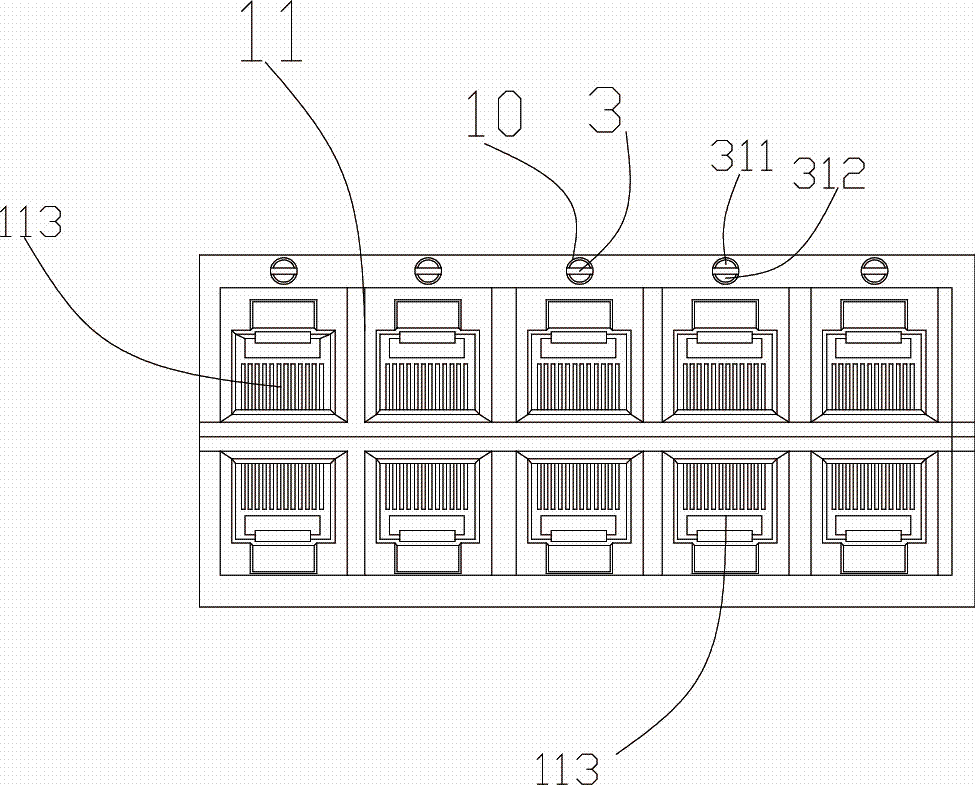

[0015] see figure 1 to Figure 4 As shown, the optical fiber main distribution frame includes a rack 1, and a module 11 is arranged on the rack 1, and the module 11 includes an in-line module 111 and a row module 112, and the in-line module 111 and the row module 112 They are respectively arranged on the front and rear surfaces of the rack 1. The row modules 111 include multi-layer row rows composed of 96-core terminal panels. Horizontal wire slots 12 are arranged under each row row. The row modules 111 are composed of A plurality of 72-core integrated machine frames are arranged vertically, and an optical cable fixing plate 13 is arranged on the side of the frame 1, and the optical cable fixing plate 13 is located at the upper or lower end of the in-line module 111. It is characterized in that , the side of the frame 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com