Method and system for repairing array substrate

An array substrate and metal layer technology, applied in the field of array substrate repair method and its system, can solve problems such as poor contact of TFT, difficult bridge connection, repair failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

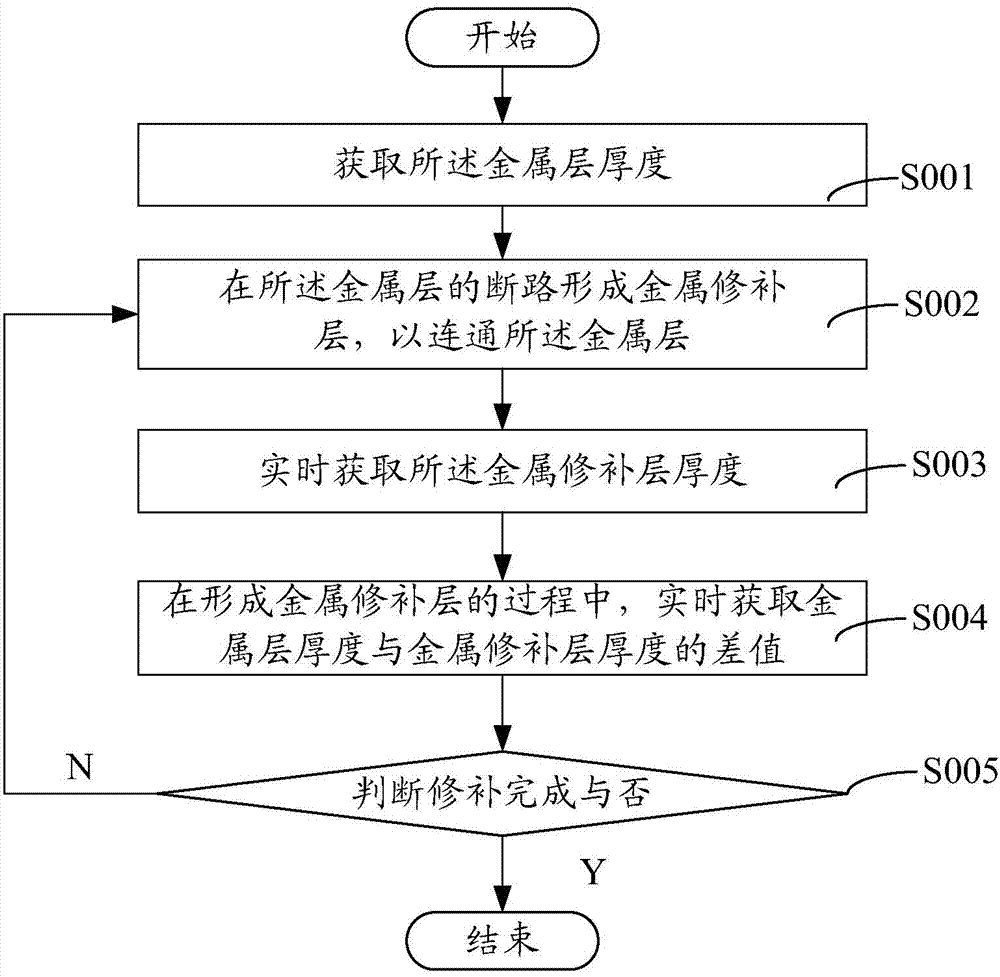

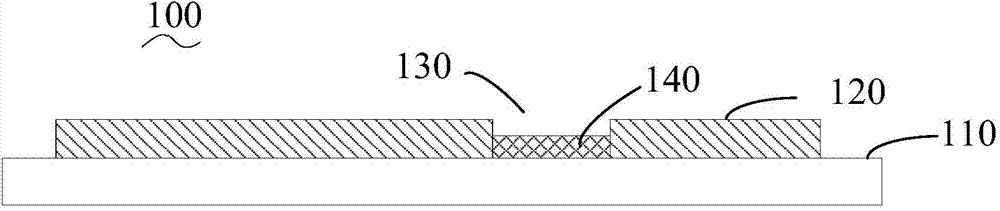

[0021] Please refer to figure 1 and figure 2 , figure 1 A flow chart of a method for repairing an array substrate, figure 2 Schematic diagram of an array substrate repaired for the array substrate repair method. The array substrate 100 includes a metal layer 120 , and there is an open circuit 130 between the metal layers 120 . The open circuit 130 may be an open circuit of a certain deposition layer of the metal layer 120 or a disconnection of several deposition layers or a fault in a metal layer. The method for repairing the array substrate comprises the following steps:

[0022] S001: Obtain the thickness of the metal layer 120 .

[0023] Acquisition of the thickness of the metal layer 120 , the thickness of the metal layer 120 obtained here is the thickness of the non-disconnected part of the metal layer 120 . In this embodiment, a thickness measurement device is used to measure the thickness of the metal layer 120 . In this embodiment, the thickness of the metal la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com