A panel lead detection device and detection method

A detection device and lead technology, which is applied in the measurement device, measurement electricity, nonlinear optics, etc., can solve the problems of poor lead detection and repair, low detection efficiency, and large detection error, so as to improve lead detection efficiency and reduce lead The effect of detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

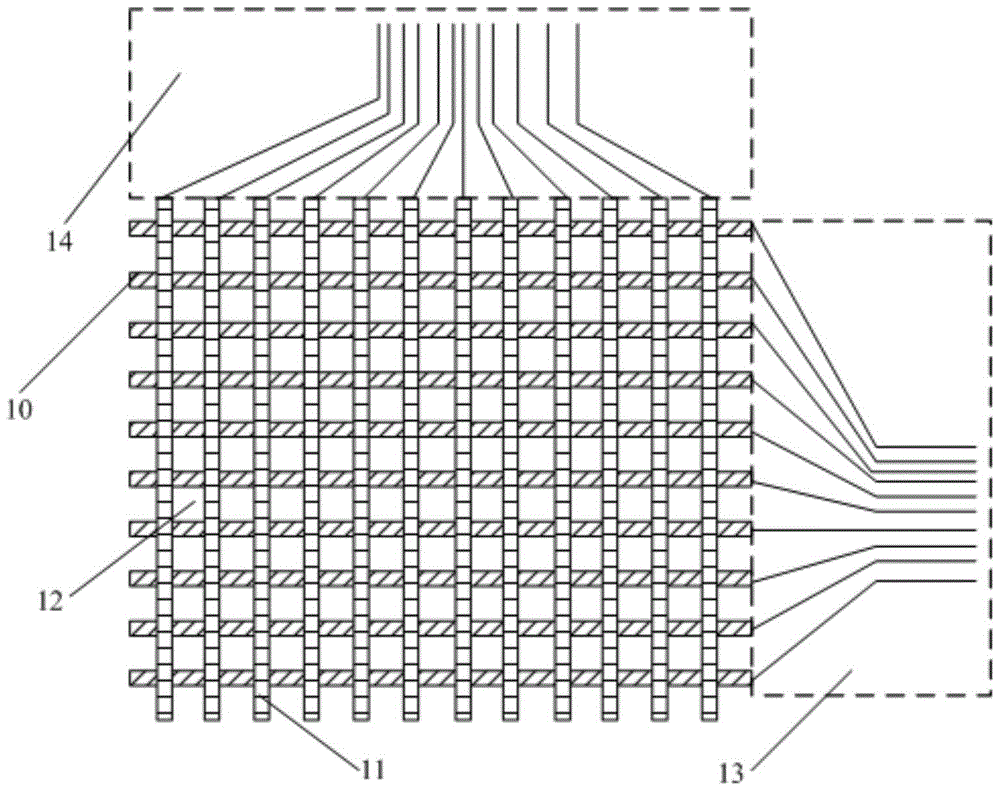

Embodiment 1

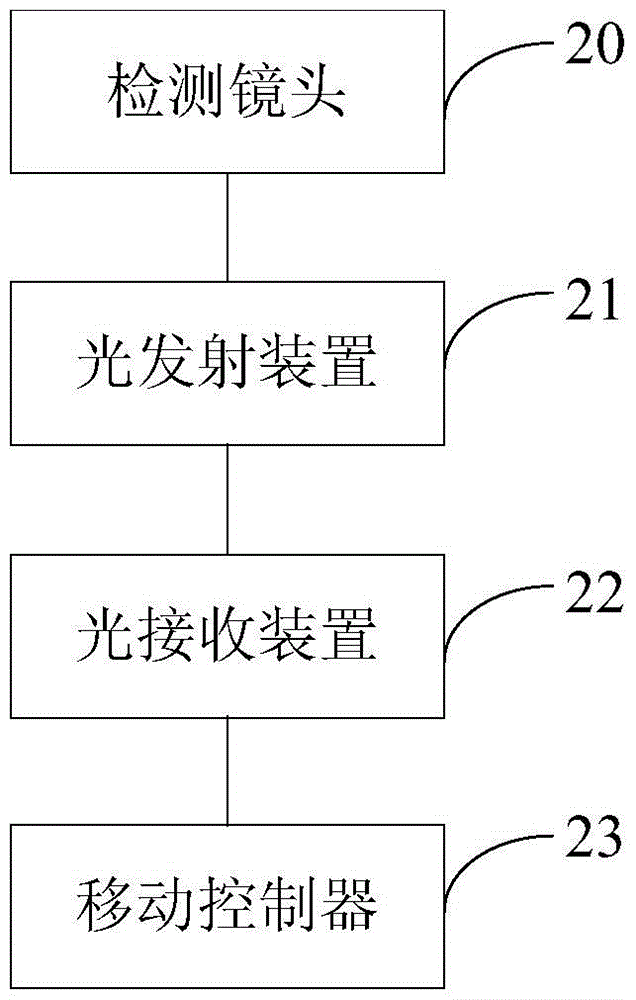

[0066] The test light collected by the detection device in the specific embodiment of the present invention is the transmitted light after the detection light passes through the lead wire to be tested. The detection device in the specific embodiment of the present invention determines that there is an abnormality in the lead wire to be detected in the lead wire area of the panel, including: open circuit of the lead wire to be detected, short circuit of the lead wire to be detected, and foreign matter on the lead wire to be detected.

[0067] When the detection device in the specific embodiment of the present invention detects the lead wire to be detected in the lead wire area of the panel, some parameters need to be initially set in the detection device, such as the detection device in the specific embodiment of the present invention according to the position coordinates of the lead wire to be detected, Parameters such as the shape of the lead wire to be detected, the lengt...

Embodiment 2

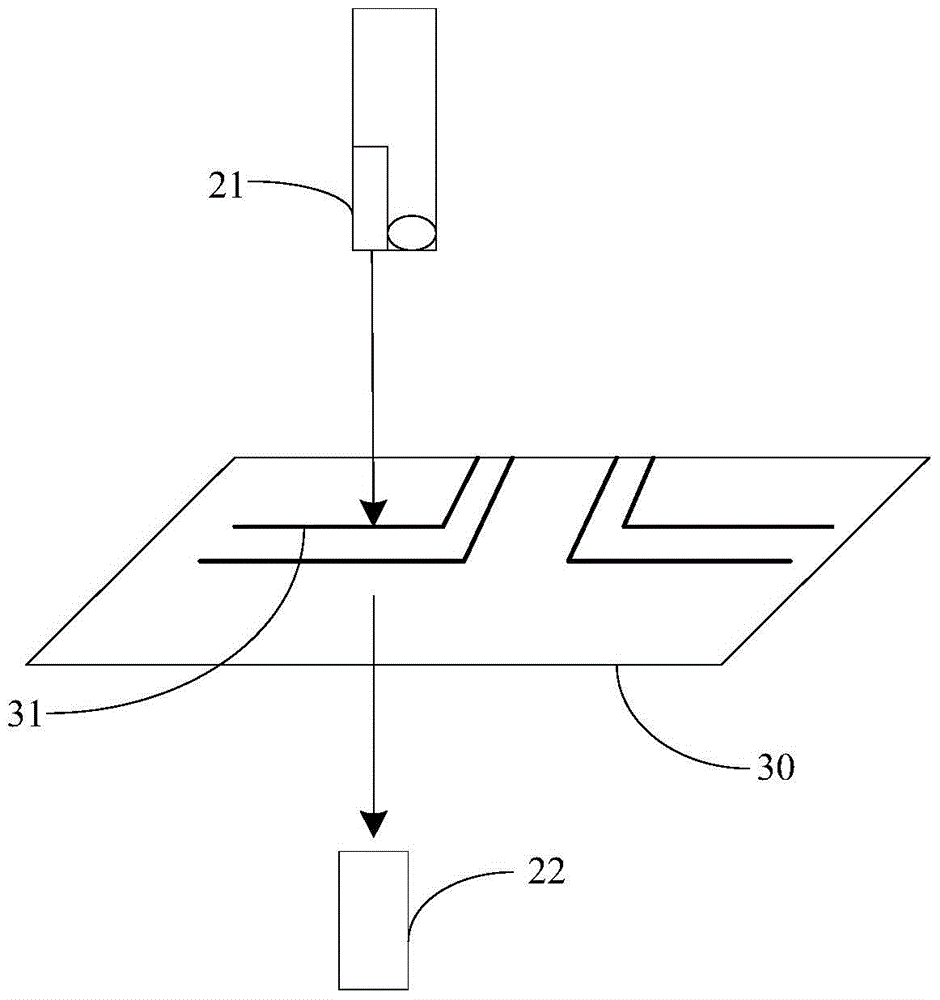

[0071] The test light collected by the detection device in the specific embodiment of the present invention is the reflected light after the detection light is reflected by the lead wire to be tested.

[0072] Such as Figure 6 As shown, when the specific embodiment of the present invention detects, the detection device first locks the initial position of the lead wire 31 to be detected; Light, the diameter of the spot 60 of the detection light is preset, preferably, the diameter d of the spot 60 of the detection light satisfies: d=L0; the detection device collects the reflected light after the detection light is reflected by the lead wire 31 to be detected, And test the intensity value of the reflected light, and use the intensity value of the reflected light obtained from the test as the initial intensity value.

[0073] Then, the detection device moves another step on the lead to be detected in the panel lead area according to the preset moving direction and moving step, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com