A kind of LED chip manufacturing method of composite transparent conductive electrode

A transparent conductive electrode, LED chip technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of high forward voltage of the chip, over-corrosion of ZnO, and increase the difficulty of the process, so as to reduce the cost of rework, the process is simple, and the reduction of The effect of craft difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

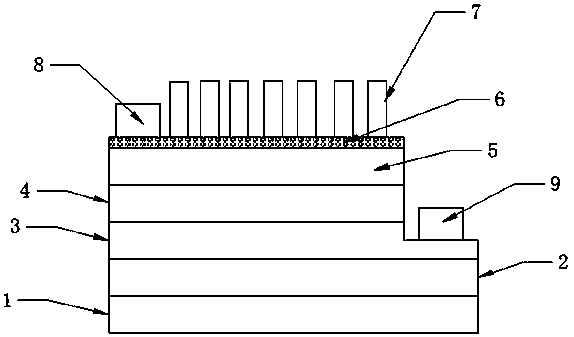

[0026] Embodiment 1: as figure 1 As shown, an LED chip with a composite transparent conductive electrode is prepared by MOCVD on Al 2 o 3 Or on the GaN substrate (1) sequentially grow gallium nitride buffer layer (2), N-GaN layer (3), quantum well layer (4), P-GaN layer (5); coating on the P-GaN layer A layer of photoresist, then exposure and development, and one side of the P-GaN layer is etched to the N-GaN layer (3) by ICP (Reactive Ion Etching); first, graphene oxide and polymethacrylate The ester (PMMA) material is uniformly mixed and coated on the substrate wafer, so that the graphene oxide can be tightly attached to the wafer in the reactor without being blown away by the carrier gas or protective gas, and the PMMA Also play the mechanical support effect to reaction product-graphene; 2 is the carrier gas, N 2 In order to protect the gas, a layered film (6) of graphene is obtained by chemical vapor deposition; the layered film (6) prepared in the above steps is immer...

Embodiment 2

[0027] Embodiment 2: as figure 1 As shown, an LED chip with a composite transparent conductive electrode is prepared by MOCVD on Al 2 o 3Or on the GaN substrate (1) sequentially grow gallium nitride buffer layer (2), N-GaN layer (3), quantum well layer (4), P-GaN layer (5); coating on the P-GaN layer A layer of photoresist, then exposure and development, and one side of the P-GaN layer is etched to the N-GaN layer (3) by ICP (reactive ion etching method); first, graphene and polymethyl methacrylate (PMMA) materials are uniformly mixed and coated on the substrate wafer, so that graphene can be tightly attached to the wafer in the reactor without being blown away by the carrier gas or protective gas, and PMMA also acts To the mechanical support of the reaction product-graphene; the above-mentioned material is placed in a medium temperature tube furnace, with H 2 is the carrier gas, N 2 In order to protect the gas, a layered film (6) of graphene is obtained by chemical vapor ...

Embodiment 3

[0028] Embodiment 3: as figure 1 As shown, an LED chip with a composite transparent conductive electrode is prepared by MOCVD on Al 2 o 3 Or on the GaN substrate (1) sequentially grow gallium nitride buffer layer (2), N-GaN layer (3), quantum well layer (4), P-GaN layer (5); coating on the P-GaN layer A layer of photoresist, then exposure and development, and one side of the P-GaN layer is etched to the N-GaN layer (3) by ICP (Reactive Ion Etching); first, graphene oxide and polymethacrylate The ester (PMMA) material is uniformly mixed and coated on the substrate wafer, so that the graphene oxide can be tightly attached to the wafer in the reactor without being blown away by the carrier gas or protective gas, and the PMMA Also play the mechanical support effect to reaction product-graphene; 2 is the carrier gas, N 2 In order to protect the gas, a layered film (6) of graphene is obtained by chemical vapor deposition; the layered film (6) prepared in the above steps is immer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com