P-N junction-type compoud semiconductor light-emitting diode

A technology of light-emitting diodes and nitride semiconductors, applied in semiconductor lasers, semiconductor devices, lasers, etc., can solve the problems of inconvenient emission absorption light-emitting devices, and achieve the effect of excellent reverse breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0041] Hereinafter, the present invention will be specifically described by citing an example of manufacturing a pn junction type compound semiconductor LED using a single boron phosphide semiconductor layer formed on a p-type gallium nitride (GaN) layer as an example.

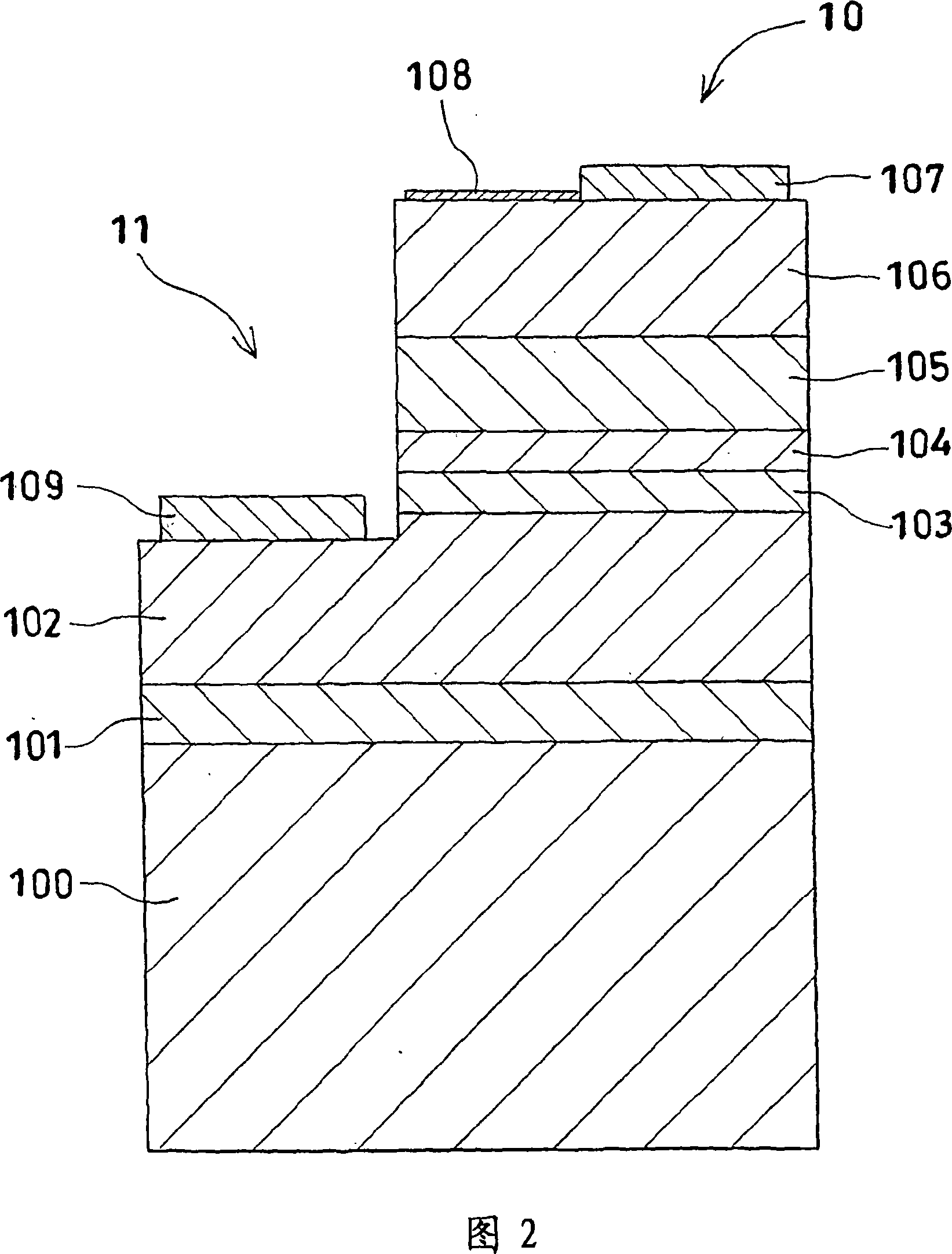

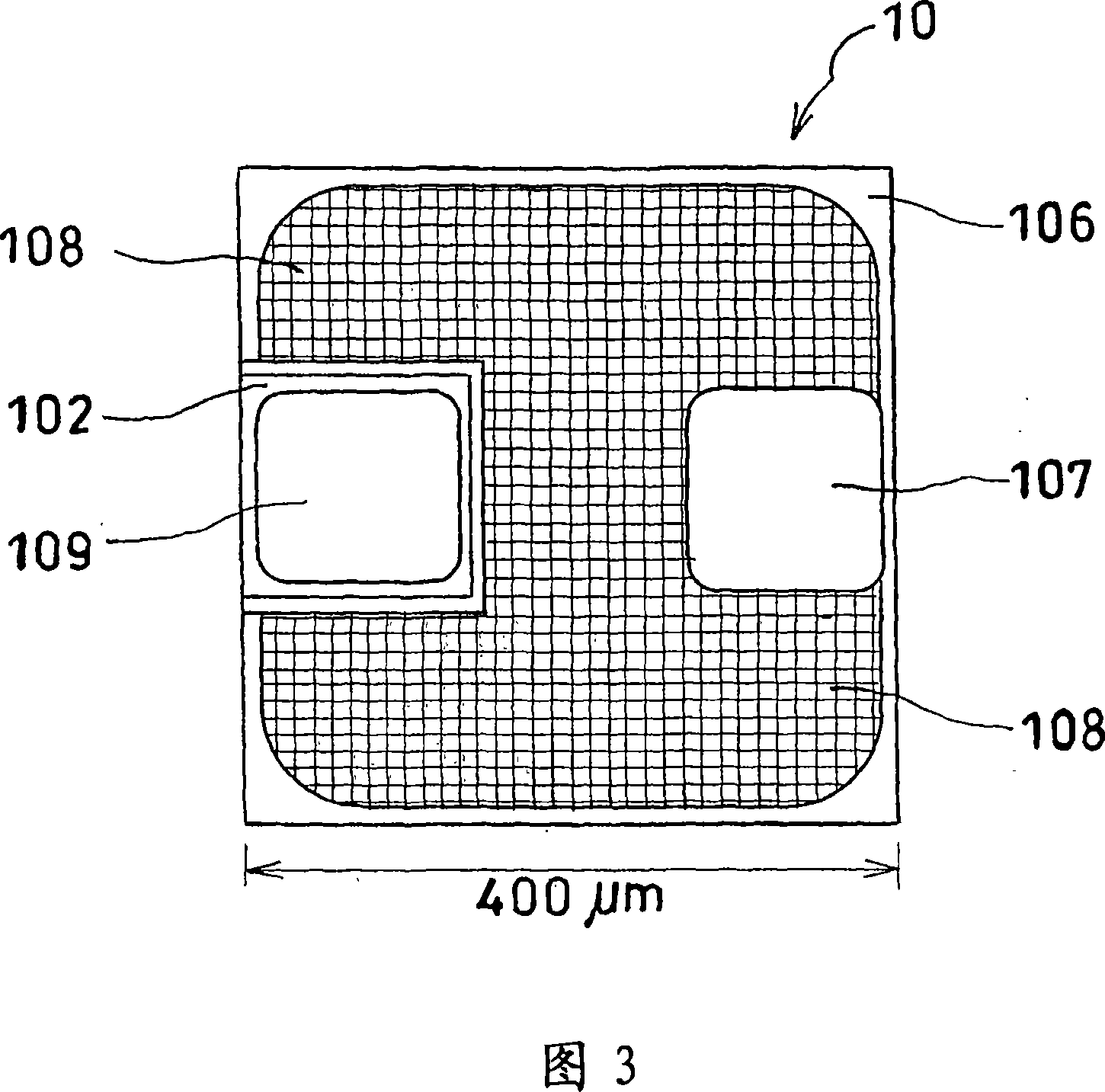

[0042] Fig. 2 schematically shows a cross-sectional view of a stack structure 11 for manufacturing an LED 10 having a double hetero (DH) junction structure. FIG. 3 shows a schematic plan view of the LED 10 .

[0043] Through the (0001) sapphire (α-Al 2 o 3On a single crystal) substrate 100, an undoped buffer layer 101 formed of GaN and a lower cladding layer 102 formed of n-type GaN doped with silicon (Si) are sequentially stacked in the following order (n=7×10 18 cm -3 , layer thickness (t) = 3μm), containing undoped n-type Ga 0.86 In 0.14 N-layer light emitting layer 103, p-type Al doped with Mg 0.06 Ga 0.94 The upper cladding layer (group III nitride semiconductor layer) 104 (p=3×10) formed of N 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com