Vertical flexible compression welding device of metal conveying wire belt

A conveyor belt and welding device technology, applied in welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of rising manufacturing costs, endangering the health of welding operators, and poor working environment, so as to improve stability and consistency , improve versatility and flexibility, and save installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

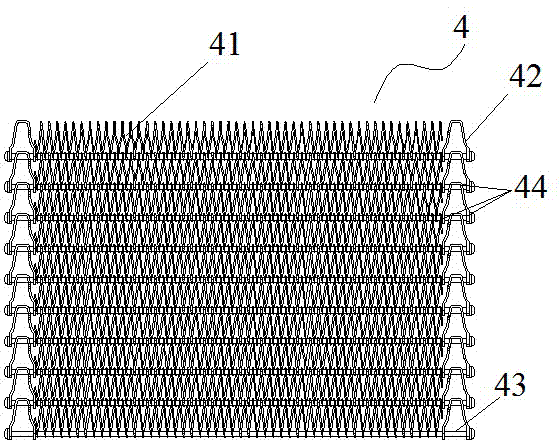

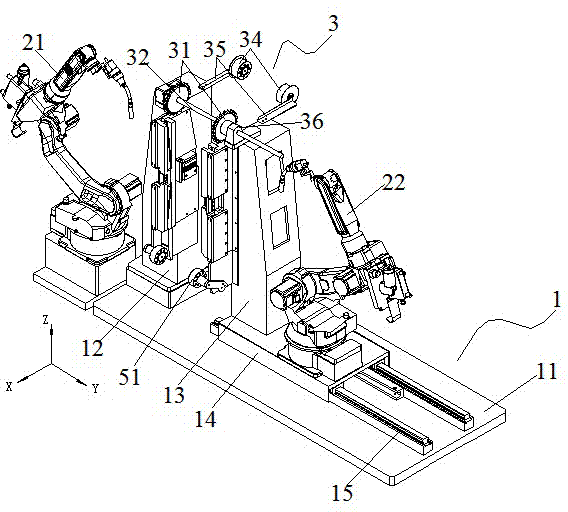

[0035] Such as figure 1 As shown, the metal conveyor mesh belt 4 is composed of three parts: a conveyor chain net 41, a horseshoe-shaped chain piece 42, and a conveyor chain bone core 43. The conveyor chain net 41 is wound on two adjacent conveyor chain bone cores 43 in a herringbone shape; A conveyor chain horseshoe-shaped chain piece 42 is respectively welded at the two ends of the chain bone core 43, and the welding point 44 is as figure 1 shown. As mentioned above, in the welding process of the prior art, the operator will clamp the metal conveyor belt 4 connected in series on a specific tooling fixture, and use the tooling fixture to laterally squeeze the conveyor chain net 41 to free up the welding. Then, the operator holds a welding torch in one hand and a welding wire in the other, and welds the horseshoe-shaped chain piece 42 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com