Electroplating hanger hook off heavy metal waste nitric acid recycling device and recycling method

A technology for removing heavy metals and electroplating hangers, which is applied in the direction of nitric acid, nitrogen oxides/oxygen-containing acids, etc., can solve the problems of potential safety hazards and manpower consumption of waste nitric acid, and achieve the goal of preventing explosions, eliminating potential safety hazards, and reducing recycling costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

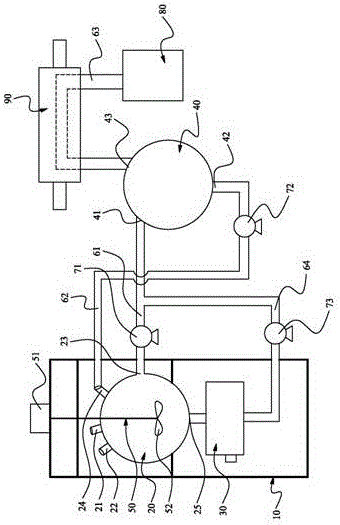

[0035] Please refer to figure 1 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a support 10 and a reaction kettle 20 , a drying device 30 and a still 40 arranged on the support 10 .

[0036] Wherein, the reaction kettle 20 is used to hold waste nitric acid and sulfuric acid containing heavy metals. The reaction kettle 20 is a glass kettle, which has strong acid and alkali resistance. The reaction kettle 20 has a feed port 21, a feeding port 22, The liquid output port 23, the input port 24 and the sediment output port 25 are used again. The reactor 20 is provided with a stirring device 50. Specifically, the stirring device 50 includes a motor 51 and a stirring paddle 52 driven by the motor 51 to rotate. , the stirring paddle 52 is installed on the output shaft of the motor 51 and the stirring paddle 52 is located in the reaction kettle 20 , and the motor 51 is fixed on the bracket 10 .

[0037] The distillation still 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com