Electric clipper control system

A control system and technology of electric scissors, applied in the direction of use feedback control, etc., can solve problems such as low safety factor, hidden safety hazards, and limited customer demand, and achieve the goals of avoiding hidden dangers, safe use, and efficient cutting work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

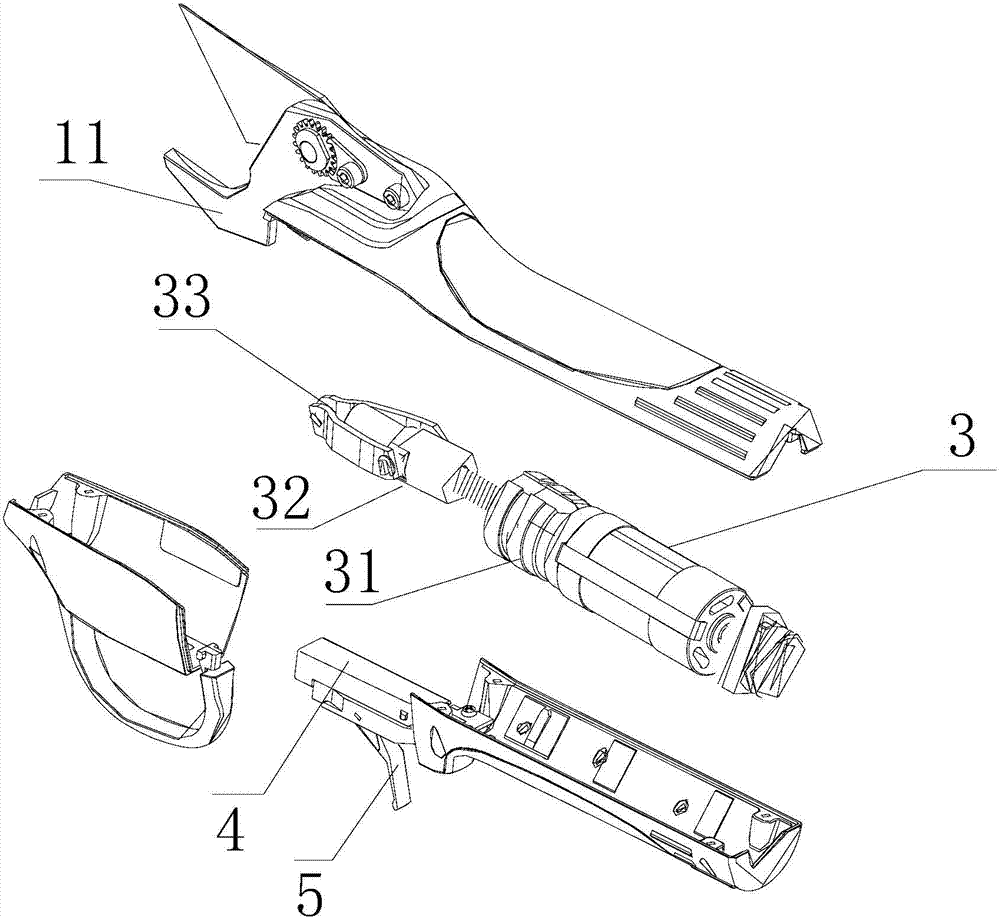

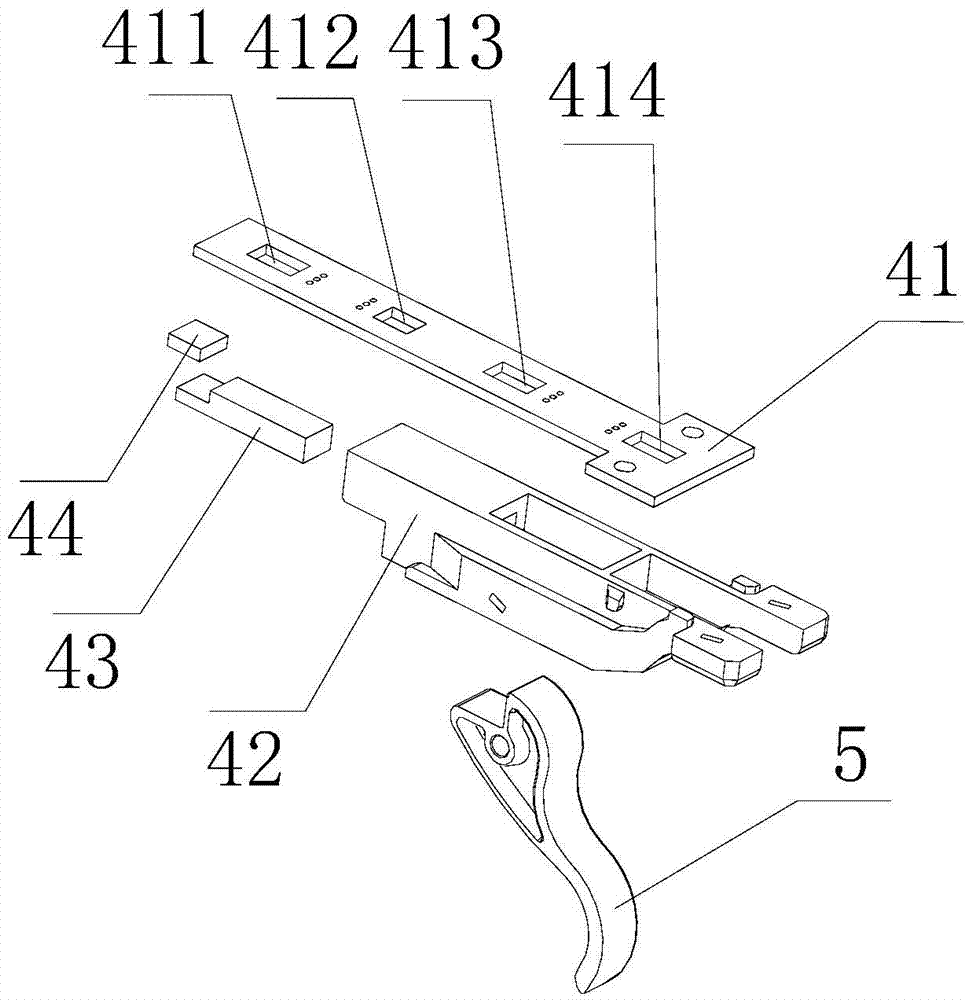

[0021] refer to Figure 1 to Figure 3 As shown, it is an electric scissors applying the control system of the present invention. The electric scissors are driven by a motor 3 housed in the scissors main body. The motor 3 is connected with a reducer 31. The end of the rod 32 is connected with a connector 33 for driving the opening and closing angle of the scissors head 11. The electric scissors have two opening modes, a large opening and a small opening, and the switching of the opening mode of the scissors head is realized through a control system. The system includes a sensing device 4 for sensing the trigger position and a controller for receiving the sensing signal of the sensing device 4, wherein the sensing device 4 is a Hall travel plate 41 with a plurality of positions and cooperates with it A magnet 44 that can slide thereon, the magnet 44 is fixed on the magnet holder 43 in the trigger bracket 42, one end of the magnet holder 43 is fixedly connected with the return sp...

Embodiment 2

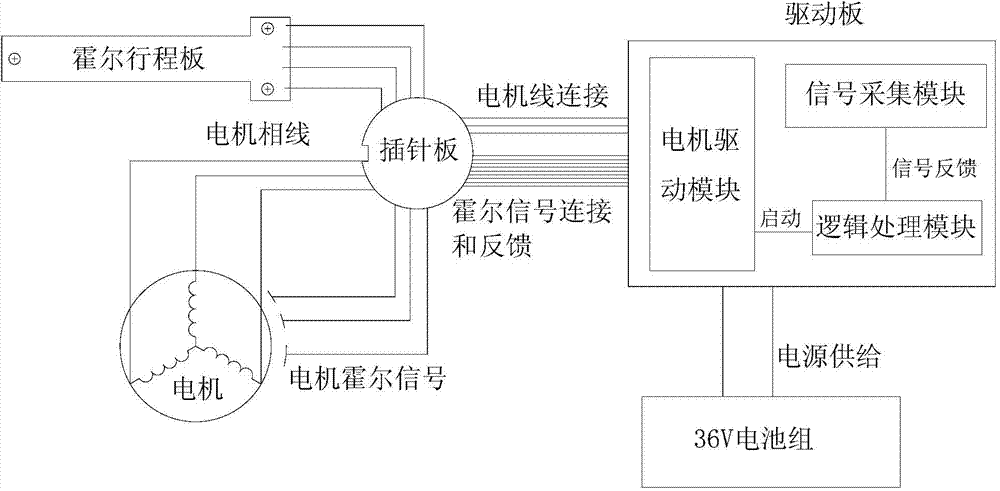

[0029] Such as Figure 4 As shown, as the second preferred embodiment of the present invention, the control system includes a servo frequency conversion processor, the input end of the servo frequency conversion processor is connected to a DC power supply, and the output end of the servo frequency conversion processor is connected to a three-phase AC servo motor. The servo frequency conversion processor is also connected with three control switches, which are start switch, forward rotation switch and reverse switch. The start switch is used to control the running state of the whole system. When the start switch is in the enable position, the system circuit is connected, and the DC The power supply inputs the DC voltage into the servo frequency conversion processor. After the servo frequency conversion process, the DC voltage is converted from DC input to AC output to drive the three-phase AC servo motor, so that the three phases of the three-phase AC servo motor start at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com