Current limit control method and current limit control device of three-level inverter

A three-level inverter and current-limiting control technology, applied in the electronic field, can solve problems such as positive and negative busbar mutual irrigation, output voltage waveform difference, single-side busbar is large, etc., to prevent overvoltage, good output waveform, avoid Effects of too frequent movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments, taking the resistive load as an example.

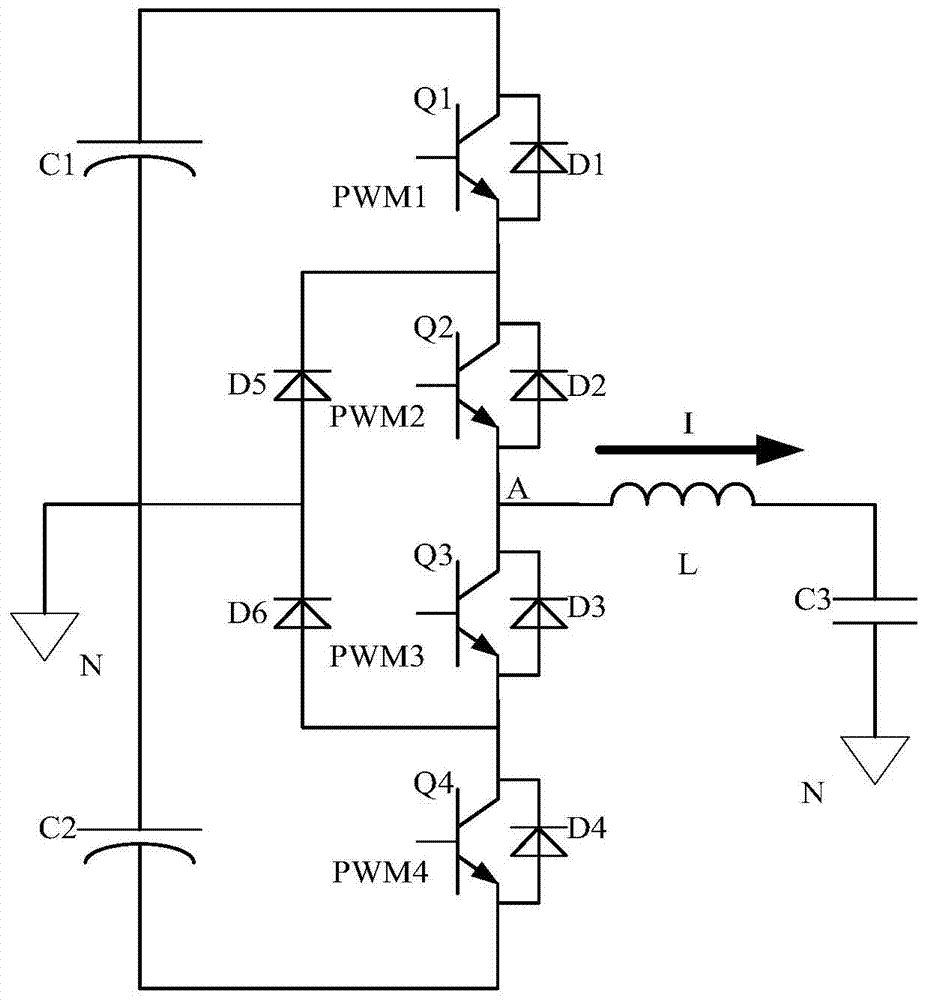

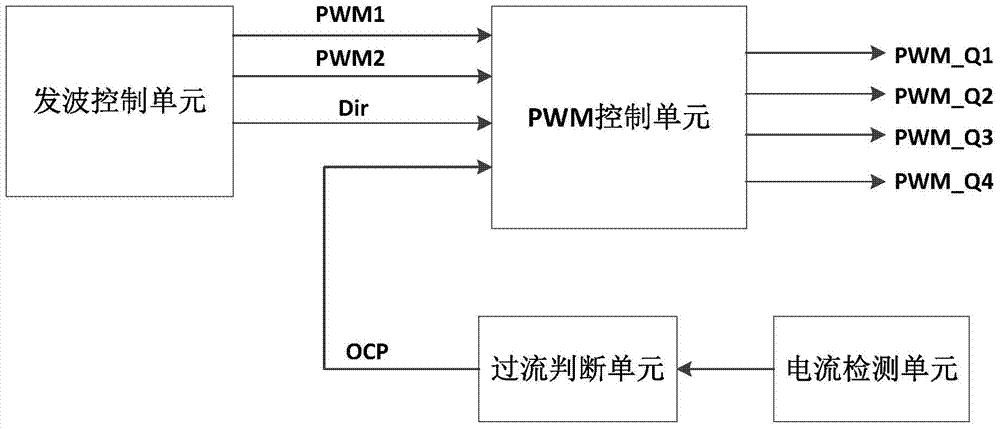

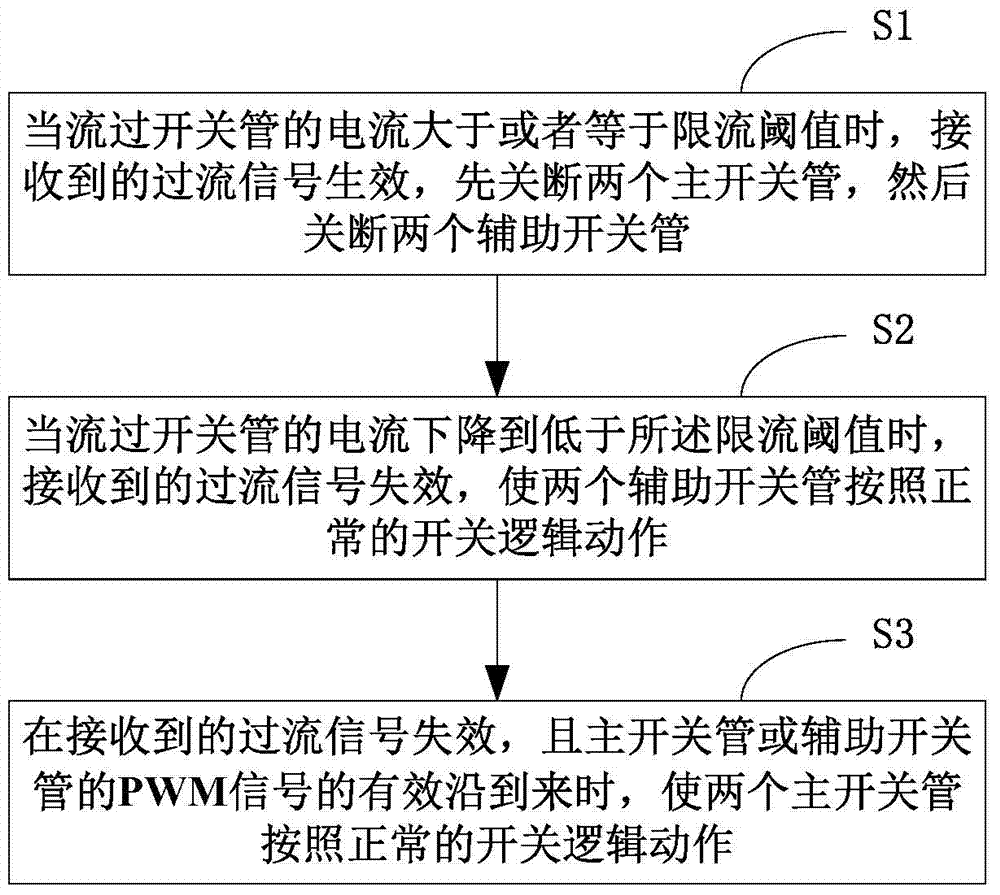

[0052] see figure 1 , the three-level inverter at least includes a bridge arm composed of four switching tubes connected in series in sequence, the four switching tubes are the main switching tube Q1 and the auxiliary switching tube Q2 located in the upper bridge arm, and the main switching tube located in the lower bridge arm Tube Q4 and auxiliary switch tube Q3. see figure 2 , in the current limiting control system of the three-level inverter, the wave control unit is used to output the direction signal (Dir) that the current voltage is in the positive half cycle or negative half cycle, and two complementary PWM signals with dead zones to the PWM The control unit is the PWM signal of the main switching tube—PWM1, and the PWM signal of the auxiliary switching tube—PWM2. The PWM control unit generates four PW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com