A kind of fresh meat sub-supercooling preservation method

A fresh-keeping method and technology for fresh meat, applied in the direction of preservation of meat/fish by freezing/cooling, etc., can solve the problems of high accuracy requirements of storage temperature, high energy consumption, loss of juice, etc., so as to improve the fresh-keeping effect and ensure Economic benefits, the effect of preventing juice loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A sub-supercooled preservation method for fresh meat, comprising the following steps:

[0037] Step 1. Select three parts of fresh beef tenderloin from non-epidemic areas and meet the hygienic requirements as raw materials, each weighing about 1kg, and use polyvinyl chloride plastic wrap for single-layer wrapping.

[0038] Step 2: Put the first portion of wrapped fresh meat into a fresh-keeping store at -3 to -7°C, with a relative humidity of 80%, and place it crosswise without stacking for storage.

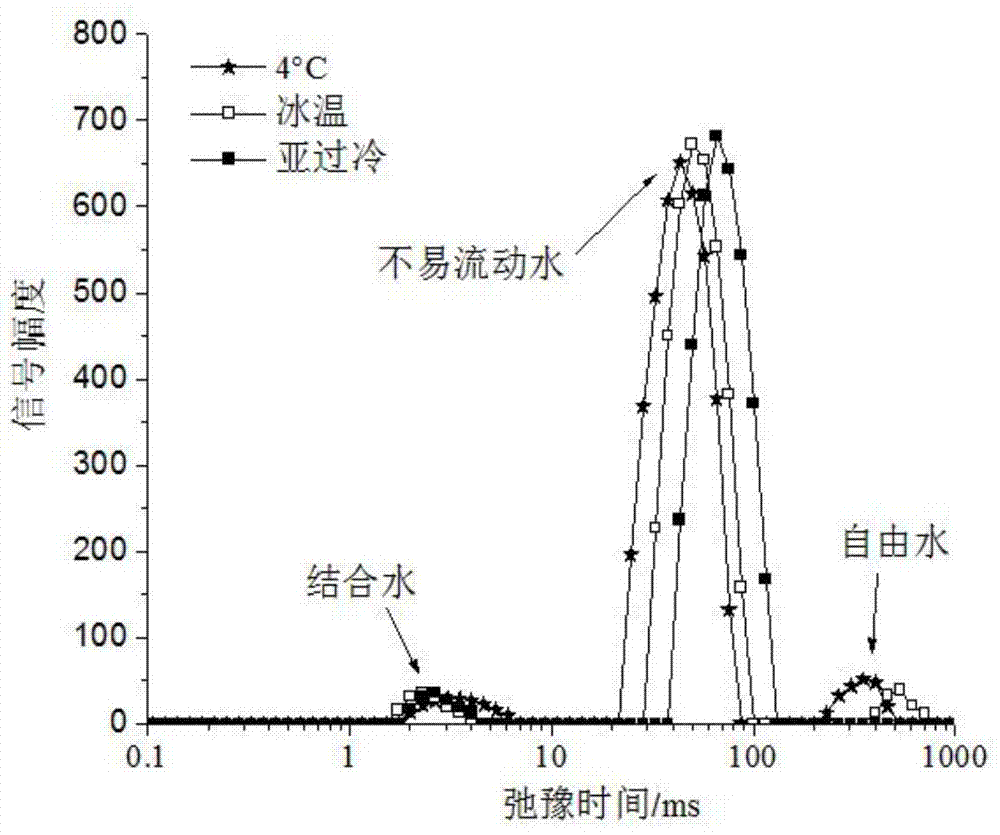

[0039] Step 3: Adjust the temperature in the warehouse to -5.5~-7°C, and maintain it for 11 hours. At this time, the free water in the fresh meat freezes rapidly, and the weight of the meat sample basically remains unchanged.

[0040] Step 4. Adjust the temperature in the warehouse to -3~-5.5°C. At this time, the fresh meat is in a shallow freezing state where the free water is completely frozen, and the water that is not easy to flow and the bound water are not frozen. s...

Embodiment 2

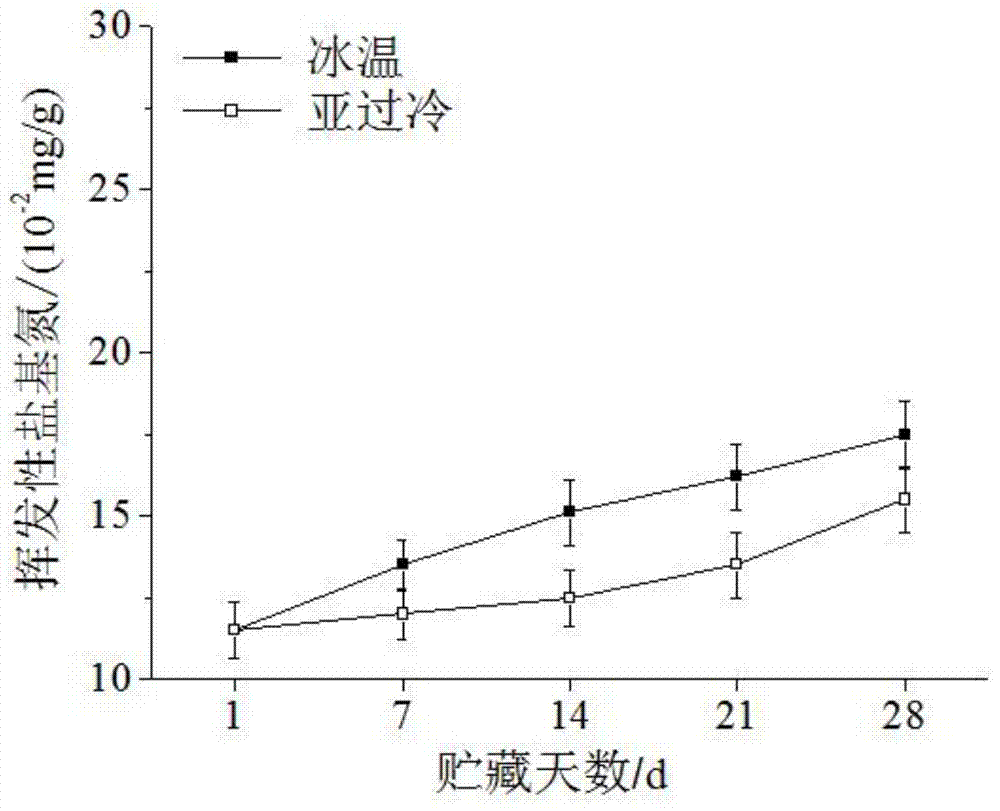

[0047] A sub-supercooled preservation method for fresh meat, the steps of which are the same as Steps 1, 2, 3 and 4 of Embodiment 1, only the fresh beef tenderloin is replaced with lamb tenderloin and lamb hind leg. The results show that, compared with the traditional fresh-keeping at 4°C and ice temperature preservation, the sub-supercooled fresh-keeping method for fresh meat of the present invention can reduce the content of volatile basic nitrogen in lamb tenderloin samples and lamb hind leg meat samples, and inhibit microorganisms. growth, thereby increasing the storage time; at the same time, the shallow freezing state can reduce the loss of water, reduce the loss of juice, and improve economic benefits.

[0048] The traditional 4°C fresh-keeping method not only shortens the storage time, but also causes serious storage loss and quality deterioration; although ice-temperature storage improves the storage time and quality of fresh meat, it requires high accuracy of storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com