Preparation method and application of metal-organic framework material

A metal-organic framework, mixed solution technology, applied to 6/16 groups of organic compounds without C-metal bonds, alkali metal compounds, chemical instruments and methods, etc. problems, to achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

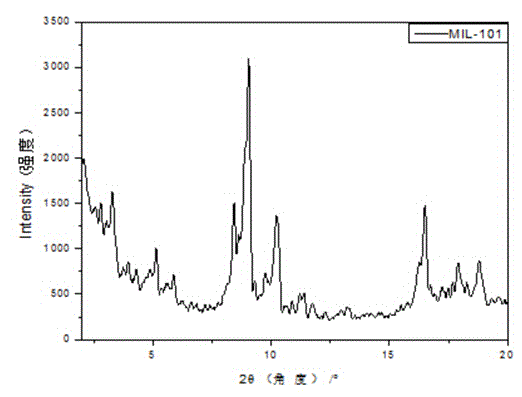

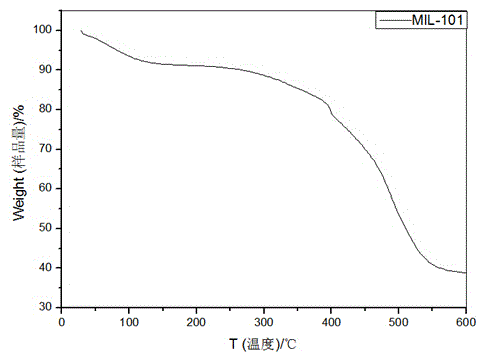

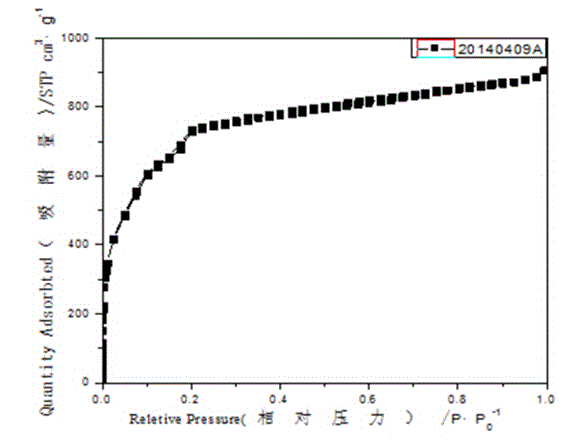

[0022] In this embodiment, the MIL-101 material prepared with hydrochloric acid as a mineralizer has a specific surface area of 1636 m 2 / g, the average pore diameter is 2.14nm.

[0023] The preparation method of above-mentioned material is as follows:

[0024] (1) Adding Cr(NO 3 ) 3 9H 2 O and H 2 Dissolve BDC in deionized water at a molar ratio of 1.5:1, slowly add 0.3ml of hydrochloric acid dropwise, stir for 15 minutes, transfer the reactant to a hydrothermal reactor and react at 200°C for 6 hours;

[0025] (2) Suction filter the product, rinse with deionized water three times and dry at room temperature;

[0026] (3) Dissolve the solid in DMF and activate it at 60°C for 5 hours, filter it with suction and wash it with DMF three times, then dry it at room temperature;

[0027] (4) Dissolve the solid in CH 3 CH 2 Activation in OH at 100°C for 16h, suction filtration, vacuum drying at 160°C for 24h to obtain MIL-101 material;

[0028] (5) Weigh 0.025g of the mater...

Embodiment 2

[0031] In this embodiment, the MIL-101 material prepared with hydrochloric acid as a mineralizer has a specific surface area of 1498m 2 / g, the average pore diameter is 2.19nm.

[0032] The preparation method of above-mentioned material is as follows:

[0033] (1) Adding Cr(NO 3 ) 3 9H 2 O and H 2 Dissolve BDC in deionized water at a molar ratio of 1:1, slowly add 0.4ml of hydrochloric acid dropwise, stir for 20 minutes, transfer the reactant to a hydrothermal reactor and react at 180°C for 8 hours;

[0034] (2) Suction filter the product, rinse with deionized water three times and dry at room temperature;

[0035] (3) Dissolve the solid in DMF and activate it at 55°C for 5 hours, filter it with suction and wash it with DMF three times, and dry it at room temperature;

[0036] (4) Dissolve the solid in CH 3 Activation in Cl at 120°C for 24h, suction filtration, vacuum drying at 130°C for 24h to obtain MIL-101 material;

[0037] (5) Weigh 0.025g of the material powder...

Embodiment 3

[0039]In this embodiment, the MIL-101 material prepared with hydrochloric acid as a mineralizer has a specific surface area of 1512m 2 / g, the average pore diameter is 2.21nm.

[0040] The preparation method of above-mentioned material is as follows:

[0041] (1) Adding Cr(NO 3 ) 3 9H 2 O and H 2 Dissolve BDC in deionized water at a molar ratio of 0.8:1, slowly add 0.5ml of hydrochloric acid dropwise, stir and disperse for 30 minutes, then transfer the reactants to a hydrothermal reactor and react at 160°C for 7 hours;

[0042] (2) Suction filter the product, rinse with deionized water three times and dry at room temperature;

[0043] (3) Dissolve the solid in DMF and activate it at 50°C for 6 hours, filter it with suction and wash it with DMF three times, and dry it at room temperature;

[0044] (4) Dissolve the solid in CH 2 Cl 2 Activation at 80°C for 20h, suction filtration, vacuum drying at 120°C for 24h to prepare MIL-101 material;

[0045] (5) Weigh 0.025g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com