Double-station vibrating and hitting workbench of casting inner cavity residual sand removing device

A technology for cleaning castings and double stations, applied in the field of double station vibrating workbenches, can solve the problems of low work efficiency, long downtime waiting time, etc., and achieve the effect of improving work efficiency, saving operation time, and improving operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

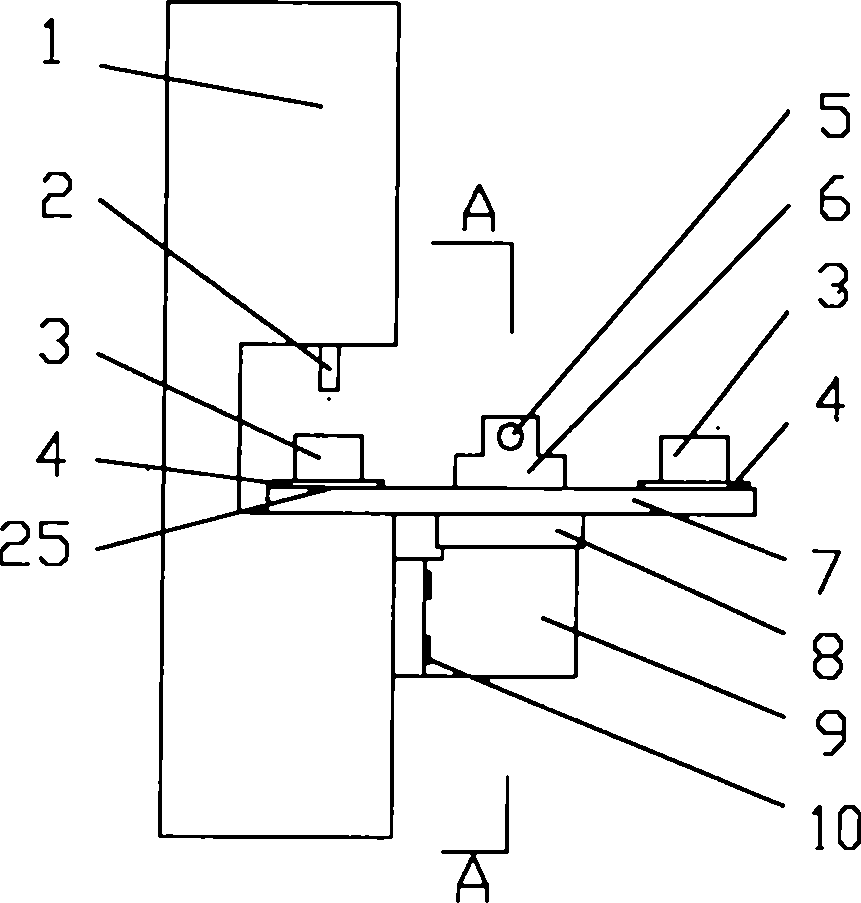

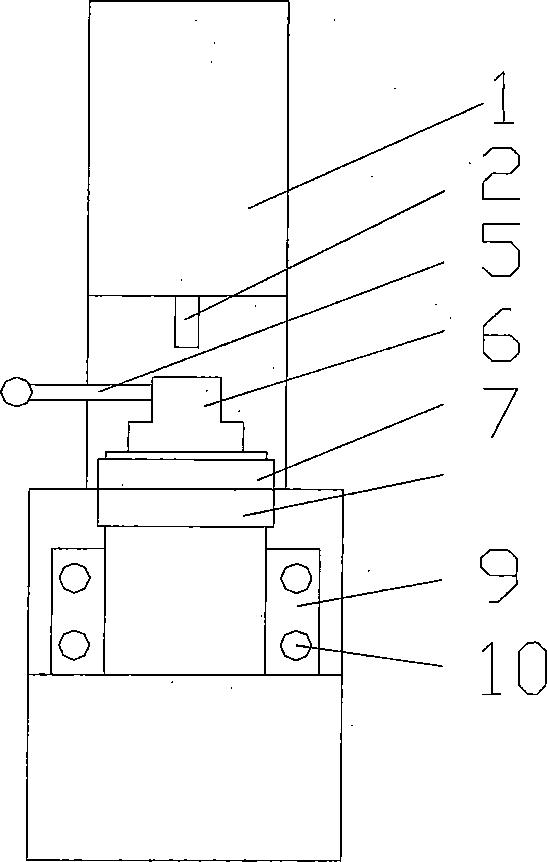

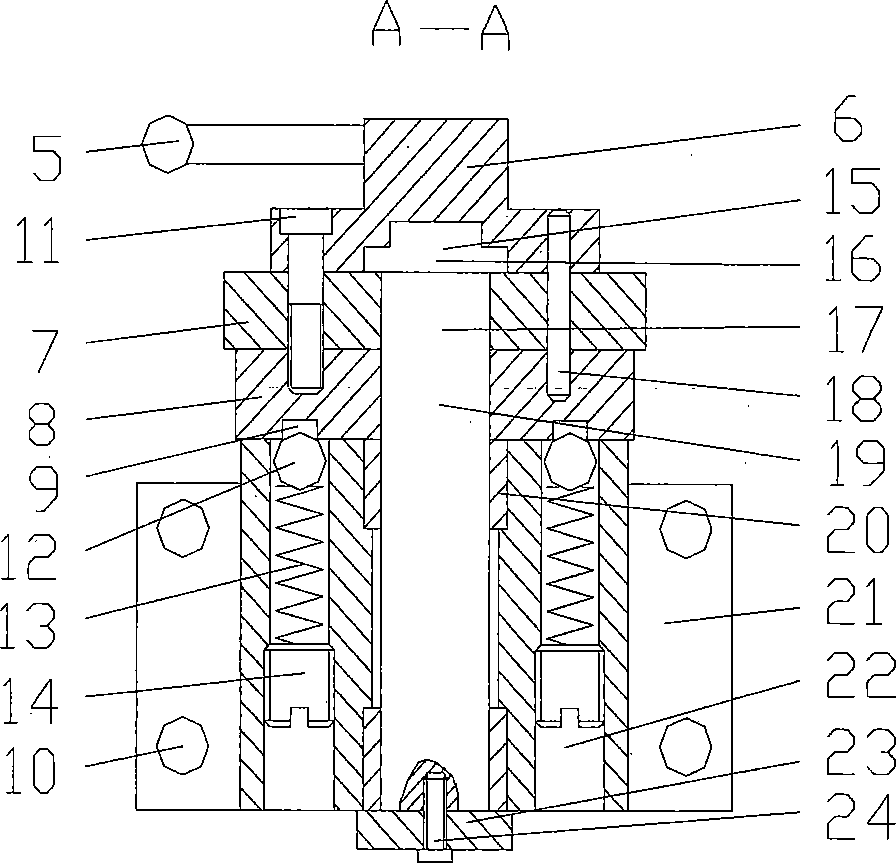

[0012] The embodiment shown in each figure is as follows: a double-station vibrating workbench for cleaning the residual sand in the inner cavity of the casting. It includes a vibration machine body 1, an air pick punch 2, and a vibration machine table top 25. It is characterized in that a support seat 21 is fixed with a screw A10 on the side of the vibrator fuselage 1 . Positioning plate 8 is housed on support base 21 . Double station platform 7 is housed above positioning disc 8 . Handle seat 6 is housed above double station table 7. Handle 5 is housed above handle seat 6. The handle seat 6, the double station table 7 and the positioning plate 8 are fixed together by the screw B11 and the positioning pin 18. A mandrel 17 is installed in the mandrel circular hole 19 in the middle of the handle base 6, the double station table 7, the positioning disc 8 and the support seat 21 from top to bottom. The mandrel 17 upper end one is contained in the handle seat circular hole 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com