High-pressure safety electric interlocking mechanism of electro-mobile, control method and electro-mobile

A high-voltage safety, electrical interlocking technology, applied in electric vehicles, control drives, electrical devices, etc., can solve the problems of increased voltage drop of the interlocking mechanism, loss of power source, endangering the safety of passengers and vehicles, etc. To achieve the effect of improving control performance and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

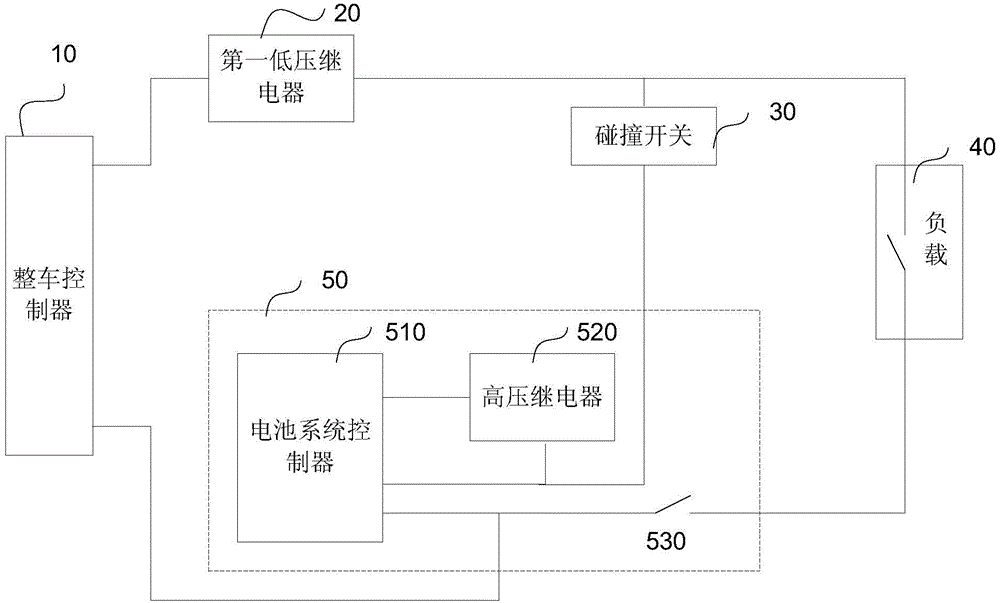

Problems solved by technology

Method used

Image

Examples

Embodiment approach

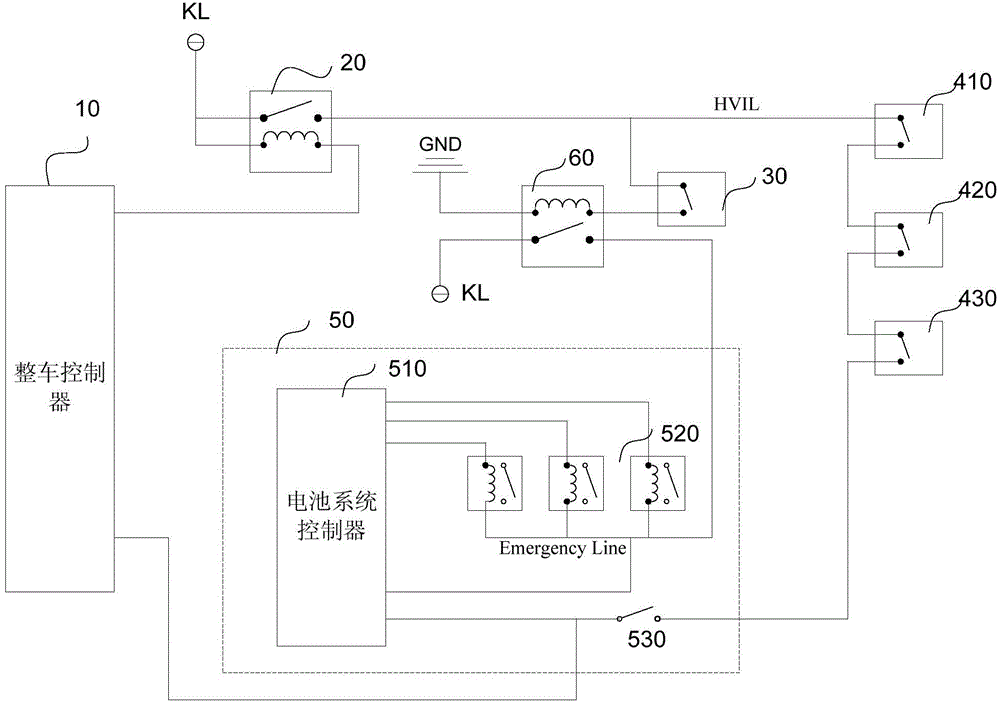

[0057] As an implementation manner, the control method may also include the following:

[0058] When the electric vehicle high-voltage safety electrical interlock mechanism is working normally, the vehicle controller 10 also detects the current vehicle speed and pedal signal of the electric vehicle, judges the current driving state according to the vehicle speed and pedal signal, and The ON state of the safety electrical interlock circuit outputs a control signal to the power battery system controller 510 .

[0059] According to the solution of the above-mentioned embodiment, the vehicle controller 10 can combine vehicle operation information, such as vehicle speed signal, accelerator pedal signal, etc., to make reasonable decisions, prevent the high-voltage relay from being forcibly disconnected by current-carrying, and avoid endangering personnel and vehicles. loss of control occurs.

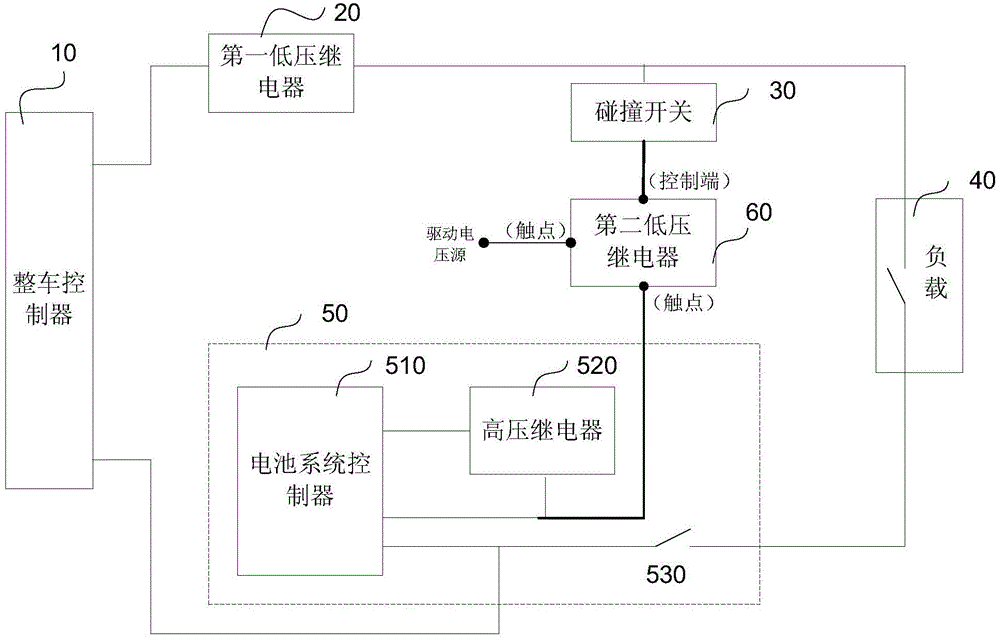

[0060] In one embodiment, refer to figure 2 As shown, the mechanism may also include: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com