System and method for treating refractory organics

A technology of refractory organic matter and oxidation system, which is applied in the field of systems for treating refractory organic matter in chemical industrial park wastewater. It can solve the problems of inability to meet the standard stably, fluctuate easily, and the difficulty of wastewater containing aromatic hydrocarbons, so as to improve the efficiency of ozone oxidation. , Reduced treatment cost, high removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

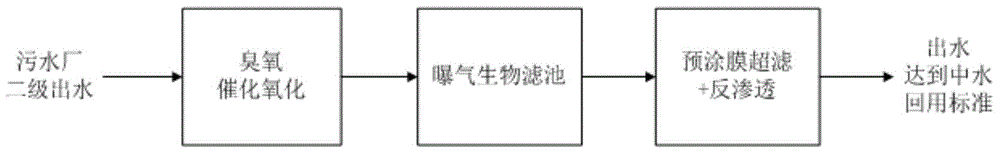

[0030] A system for treating refractory organic matter, comprising an ozone oxidation system, a biological aerated filter and an ultrafiltration membrane system, wherein the ozone oxidation system, the biological aerated filter and the ultrafiltration membrane system are sequentially connected;

[0031] The ozone catalyst used in the ozone oxidation system is TiO 2 -MnO 2 / Al 2 o 3 ;TiO 2 -MnO 2 / Al 2 o 3 The molar ratio with ozone is 0.01~5:1;

[0032] The biological aerated filter (BAF) is filled with ceramsite as a biological filling material;

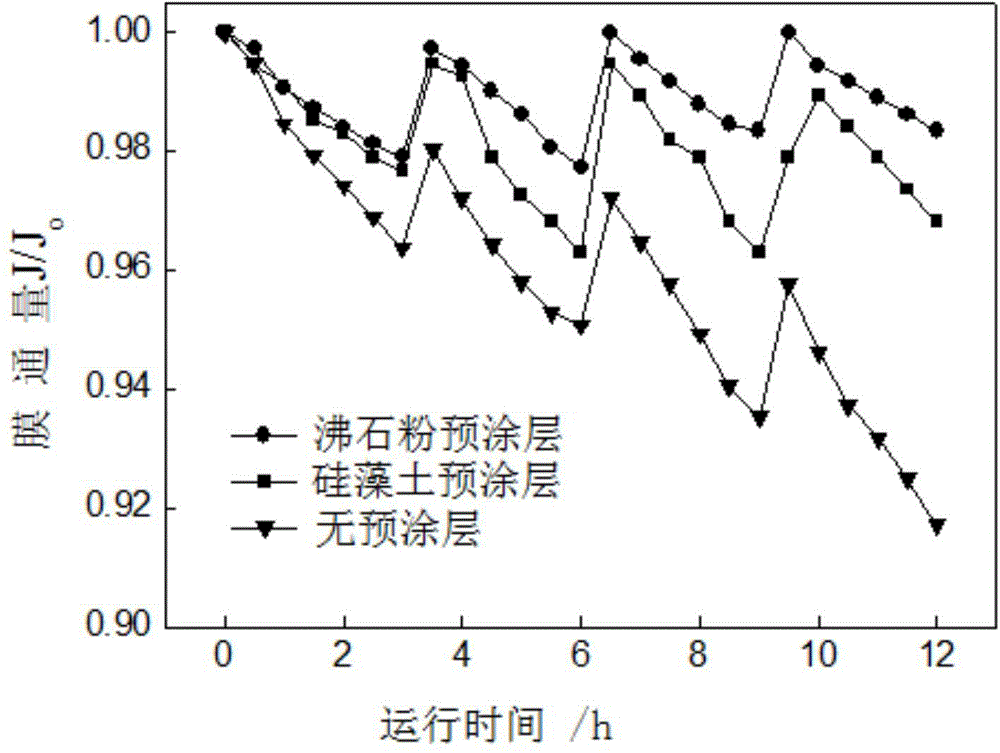

[0033] The ultrafiltration membrane system is equipped with a pre-coating layer, which is made of zeolite powder, which enters the ultrafiltration membrane through sand filtration at a rate of 100mg / L through a peristaltic pump.

[0034] Among them, TiO 2 -MnO 2 / Al 2 o 3 The ozone catalyst is prepared by "dipping-drying-roasting" process.

[0035] The biological aerated filter (BAF) is an upflow biological aerated filt...

Embodiment 2

[0039] The effluent water quality of a township chemical industrial park sewage plant is shown in Table 1:

[0040] Table 1 Water quality of effluent

[0041] water quality index pH COD NH 4 + -N Turbidity UV 254 Concentration (mg / L) 7-9 100-120 20-30 30.7-60 0.68-0.84

[0042] A method for treating refractory organic matter in the present embodiment treats the effluent of a township chemical industrial park sewage plant described in Table 1, and the steps are as follows:

[0043] (1) Ozone catalytic oxidation technology is used to pretreat the effluent of the secondary sedimentation tank of the sewage plant; among them, the ozone catalyst uses TiO 2 -MnO 2 / Al 2 o 3 ; The dosage of ozone is 15mg / L, the gas velocity is 80mg / L, TiO 2 -MnO 2 / Al 2 o3 The molar ratio of the dosage to ozone is 0.01:1.

[0044] (2) Use biological aerated filter to treat the effluent treated in step (1): the effluent enters a biological aerated filter fi...

Embodiment 3

[0049] A kind of method for processing refractory organic matter of the present embodiment treats the effluent of a certain township chemical industrial park sewage plant described in Table 1, and its steps (1), (2) are the same as embodiment 2, the difference is only in TiO 2 -MnO 2 / Al 2 o 3 The molar ratio of the dosage to ozone is 1:1.

[0050] The effluent obtained after the treatment of steps (1) and (2) is further treated by using the pre-coated ultrafiltration membrane system: the effluent enters the ultrafiltration reverse osmosis system, and the ultrafiltration reverse osmosis system uses a peristaltic pump to transfer the zeolite powder The pre-coating material is injected into the ultrafiltration membrane to form a dense "protective film" on the surface of the ultrafiltration membrane, which effectively reduces the pollution of organic matter on the membrane surface and ensures the high efficiency and long-term stable operation of the membrane system.

[0051] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap