Preparation method and preparation equipment of optical fiber preform

An optical fiber preform and equipment technology, applied in the field of optical fiber preform preparation, can solve the problems of inability to accurately control the extrusion speed of the preform rod, difficulty in forming the optical fiber preform rod, and inability to meet the requirements of special optical fiber preparation, etc., to achieve precise control , prevent bending, improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

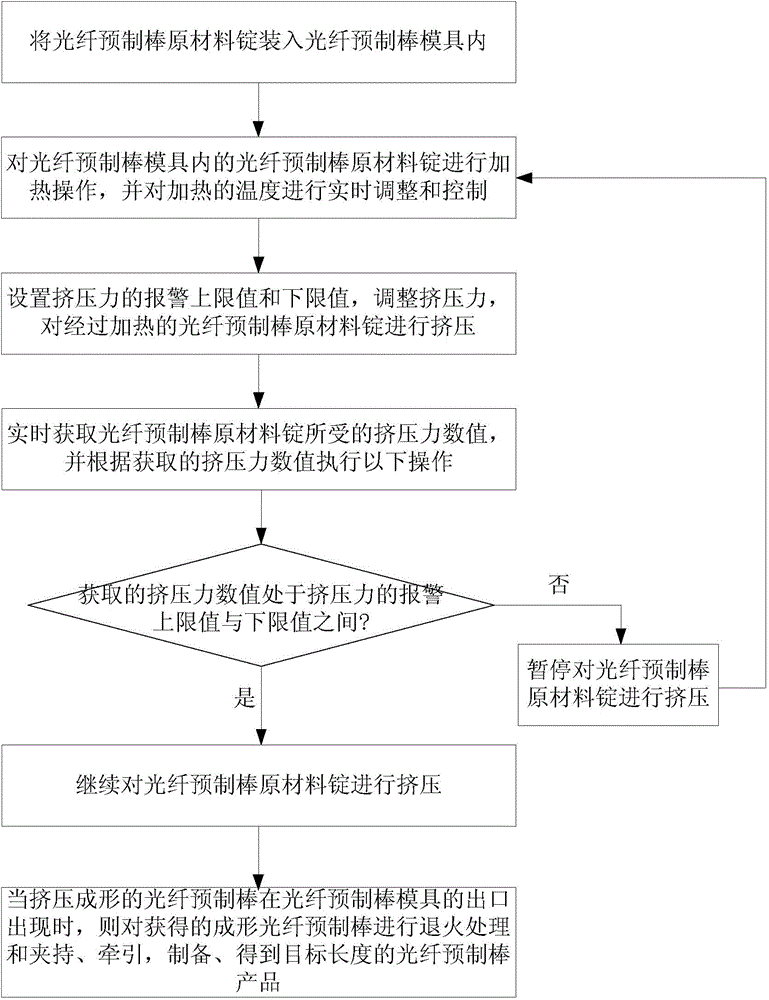

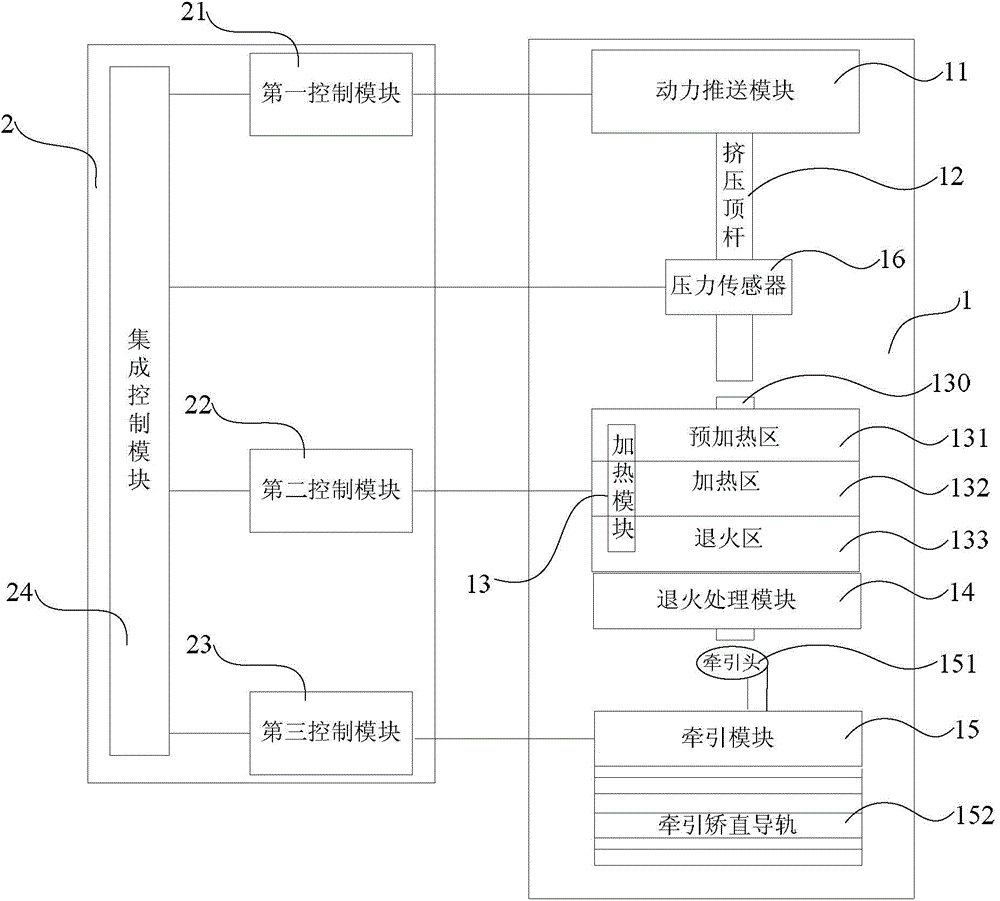

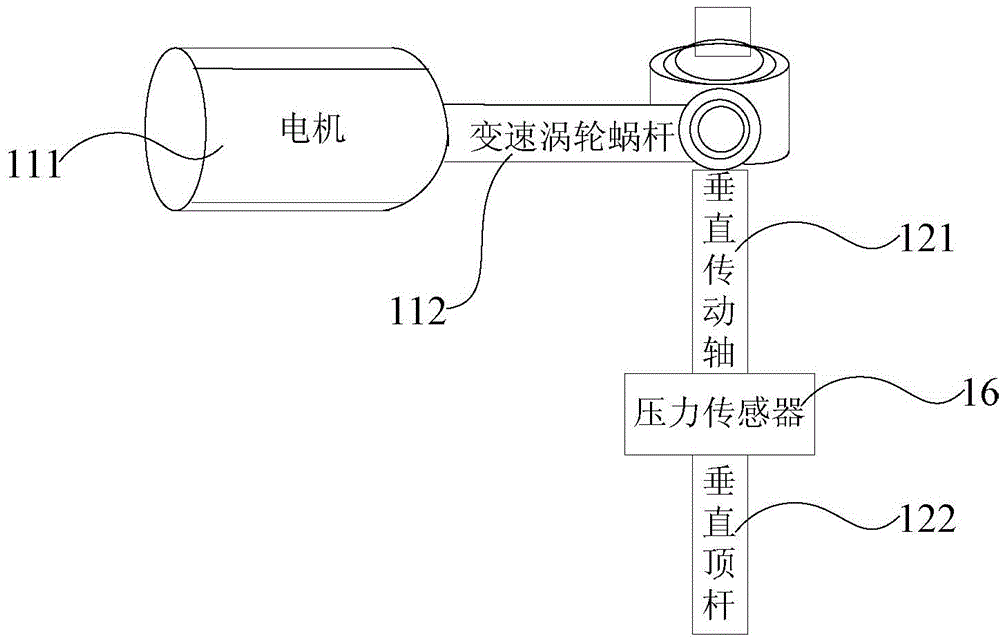

[0035] Such as figure 1 As shown, the preparation method of the optical fiber preform in this embodiment includes the following steps:

[0036] (1) Loading an optical fiber preform raw material ingot made of a chalcogenide glass material into an optical fiber preform mold;

[0037] (2) Heating the optical fiber preform raw material ingot in the optical fiber preform mold, and adjusting and controlling the heating temperature in real time:

[0038] Wherein, since the raw material ingot of the optical fiber preform is made of different materials, such as chalcogenide glass or high-temperature plastic, the heating temperature variation curve of the optical fiber preform is different. Therefore, in this step, the heating operation of the raw material ingot of the optical fiber preform includes at least a preheating process, a heating process and an annealing process, wherein:

[0039] The preheating process is responsible for preheating the optical fiber preform raw material ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com