Glass fiber reinforced polypropylene

A technology of polypropylene and copolymerized polypropylene, which is applied in the field of organic materials, can solve the problems of affecting the performance of finished products, not smooth enough, rough products, etc., and achieve the effect of increasing the output rate of finished products, reducing labor costs, and having a smooth and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

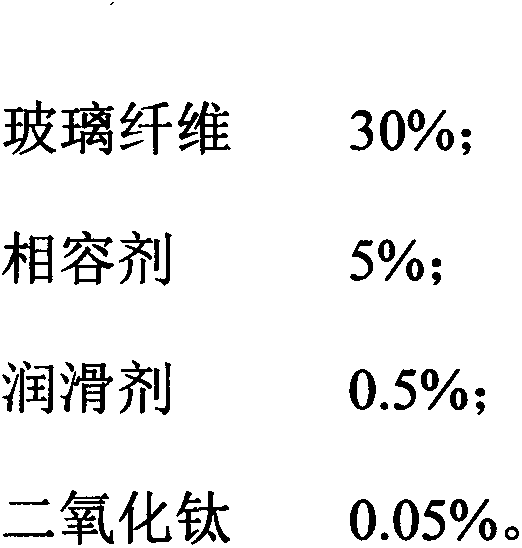

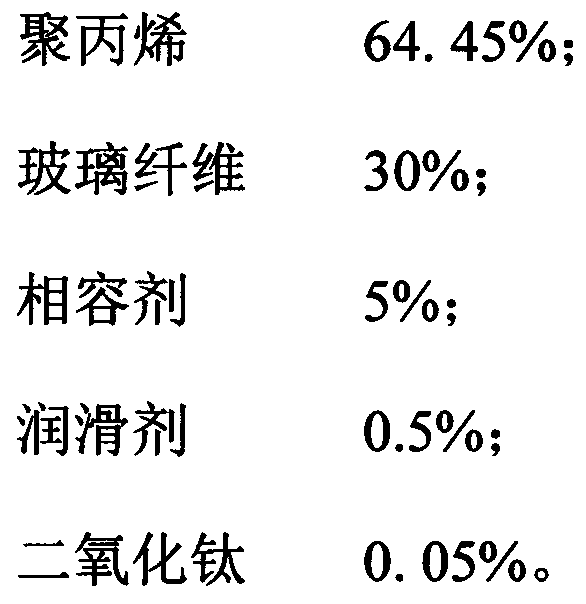

Embodiment 1

[0014] The raw materials are weighed according to the weight ratio, and the copolymerized polypropylene: 50%; the homopolypropylene: 14.45%; the compatibilizer: 5%; the lubricant: 0.5%; and the titanium dioxide 0.05%. The above-mentioned mixed materials are fed into the twin-screw extruder, and glass fibers with a weight ratio of 30% are added through side feeding, and then extruded and pelletized. The processing method of the glass-reinforced polypropylene is the same as that of the prior art, and the processing conditions are as follows: the extrusion temperature is 180-230°C, the rotating speed of the screw is 320r / min, and the injection molding temperature is 190-210°C. The glass fiber reinforced polypropylene obtained according to the above weight ratio has been tested to obtain the following physical property test data: the tensile strength is 82.53MPa; the elongation is 5.66%, the bending strength is 115.5MPa, the bending modulus is 5290MPa, and the notched impact streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com