Water-loss control agent for oil-well cement and preparation method thereof

A technology of fluid loss reducing agent and oil well cement, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of increased water loss, increased cementing risk, and prone to cementing accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

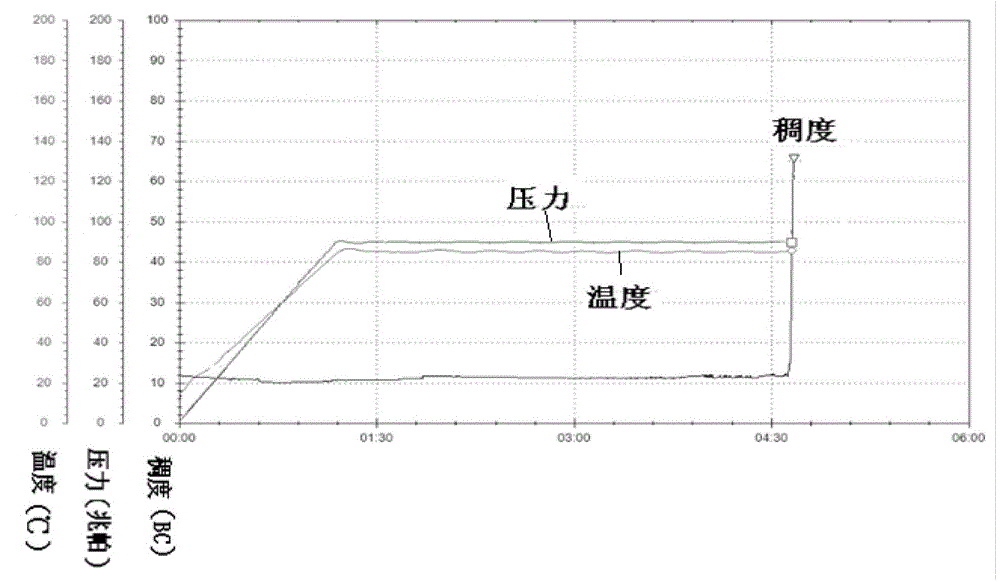

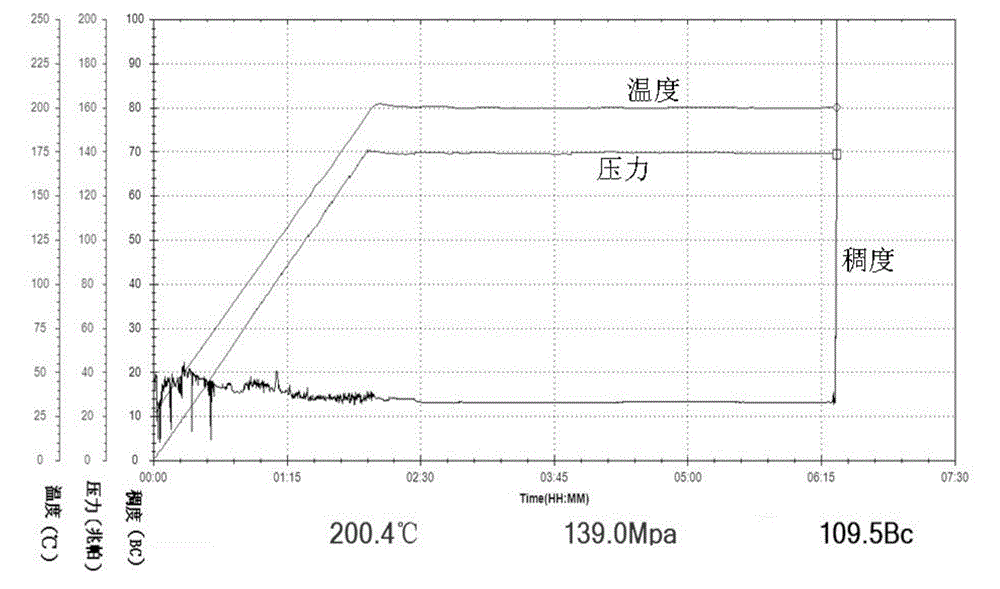

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0027] An oil well cement fluid loss reducing agent, the composition and weight ratio are as follows:

[0028] 2-acrylamido-2-methacrylic acid (AMPS), acrylamide (AM), sodium styrene sulfonate (SSS) and N-vinylpyrrolidone (NVP) monomers, the ratio of use is: 2-acrylamido- The molar ratio of 2-methacrylic acid:acrylamide:N-vinylpyrrolidone:sodium styrenesulfonate is 45:45:10:5.

[0029] Above-mentioned preparation method is as follows:

[0030] 1. The components of this fluid loss reducer are 2-acrylamido-2-methacrylic acid (AMPS), acrylamide (AM), sodium styrene sulfonate (SSS) and N-vinylpyrrolidone (NVP) monomers. Orthogonal experiments were designed to determine the optimum synthesis conditions of the copolymer: the molar ratio of AMPS / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com