Well cementation cement additive and use method thereof

A cementing cement and additive technology, applied in the field of oil field cementing, can solve problems such as low compressive strength and large water-solid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

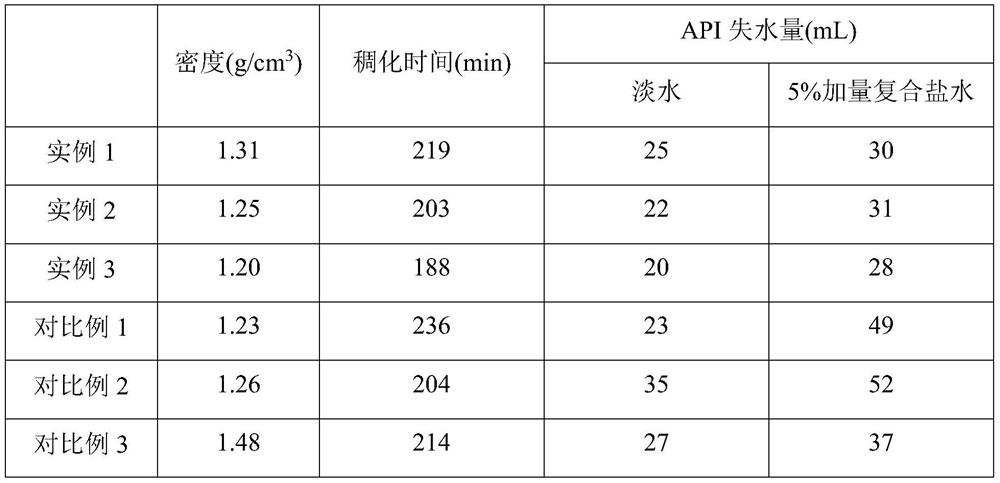

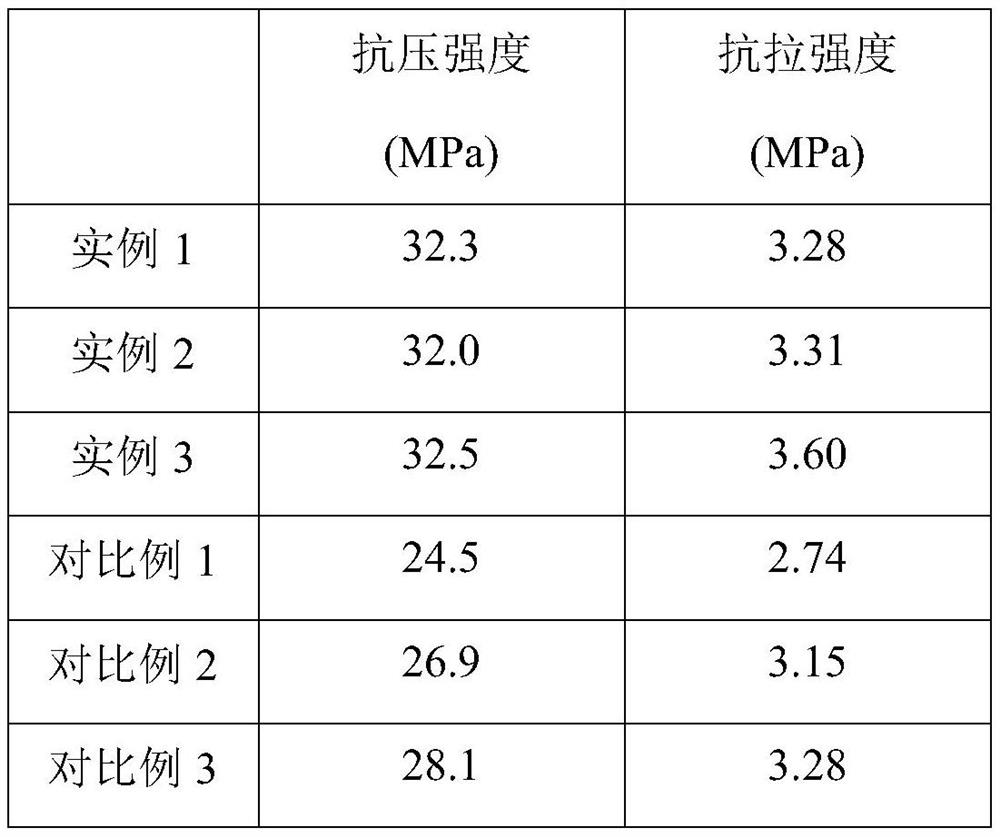

Examples

example 1

[0052] Step 1, mixing sodium alginate and water with a mass ratio of 1:10, adjusting the pH to 10 to obtain a mixed system;

[0053] Step 2. Add epichlorohydrin accounting for 5% of the mass of sodium alginate to the mixed system, react at 60° C. for 3.5 hours, add absolute ethanol, filter with suction, and dry to obtain cross-linked sodium alginate;

[0054] Step 3, dissolving the cross-linked sodium alginate in water, standing for defoaming, and preparing a 3% cross-linked sodium alginate solution by mass;

[0055] Step 4, the cross-linked sodium alginate solution is extruded into a calcium chloride solution with a mass percentage of 4% through a spinneret hole, the temperature of the coagulation bath is 40°C, and the average Cross-linked calcium alginate fibers with a diameter of 200 μm, the cross-linked calcium alginate fibers are cut to an average length of 0.5 mm;

[0056] Step 5. Mix cement and water evenly to make cement slurry, which will account for 10% of the cemen...

example 2

[0058] Step 1, mixing sodium alginate and water with a mass ratio of 1:10, adjusting the pH to 10 to obtain a mixed system;

[0059] Step 2. Add epichlorohydrin accounting for 5% of the mass of sodium alginate to the mixed system, react at 60° C. for 3.5 hours, add absolute ethanol, filter with suction, and dry to obtain cross-linked sodium alginate;

[0060] Step 3, dissolving the cross-linked sodium alginate in water, standing for defoaming, and preparing a 4% cross-linked sodium alginate solution by mass;

[0061] Step 4. The cross-linked sodium alginate solution is extruded into a calcium chloride solution with a mass percentage of 3% through a spinneret hole, and the temperature of the coagulation bath is 40° C. After traction, washing and drying, the average Cross-linked calcium alginate fibers with a diameter of 200 μm, the cross-linked calcium alginate fibers are cut to an average length of 0.5 mm;

[0062] Step 5, mix cement and water evenly to make cement slurry, ta...

example 3

[0065] Step 1, mixing sodium alginate and water with a mass ratio of 1:10, adjusting the pH to 10 to obtain a mixed system;

[0066] Step 2. Add epichlorohydrin accounting for 6% of the mass of sodium alginate to the mixed system, react at 60° C. for 3.5 hours, add absolute ethanol, filter with suction, and dry to obtain cross-linked sodium alginate;

[0067] Step 3, mixing cross-linked sodium alginate and sodium carboxymethyl cellulose in a molar ratio of 20:3 and dissolving in water, filtering and standing for defoaming to obtain a mixed spinning solution with a mass percentage of 5%;

[0068] Step 4, using 4% calcium chloride solution as the coagulation bath, extruding the mixed spinning solution into the coagulation bath through the spinneret hole, the temperature of the coagulation bath is 40°C, and then pulling, After washing and drying, cross-linked calcium alginate fibers with an average diameter of 200 μm were obtained, and the cross-linked calcium alginate fibers wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com