Composite snagging-resisting wear-resisting stretch yarn and silk stockings utilizing same

A technology of elastic wire and steel wire, which is applied in the field of steel stockings and anti-snag wear-resistant composite elastic wire. It can solve the problems of poor reusability, elastic wire breakage, and scrapped stockings, etc., to improve leg fatigue and enhance use strength. , the effect of a large degree of obedience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

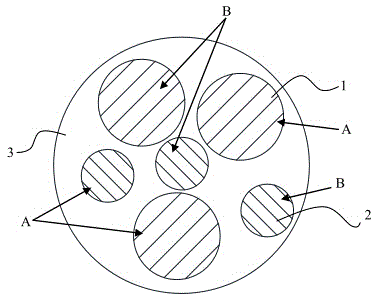

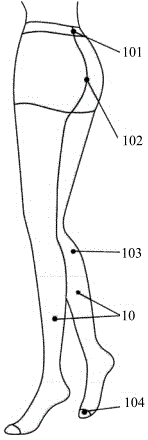

[0021] As shown in the figure, this embodiment provides an anti-snag wear-resistant composite elastic yarn, the composite elastic yarn includes a plurality of high-elastic yarns and a plurality of traction yarns, the high-elastic yarns include polyurethane high-elastic yarns, and the traction yarns The yarn includes polyester low stretch yarn and / or polypropylene low stretch yarn.

[0022] The number ratio of the plurality of high-elastic yarns and the plurality of drawing yarns is set according to the number ratio of 5:3-14, and the plurality of drawing yarns are adjacent to and arranged in parallel with the plurality of high-elastic yarns.

[0023] The anti-snag and wear-resistant composite elastic yarn of the present invention is made of a mixture of various materials, and the core is made of a core material, and phenolsulfonic acid and dihydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com