Driving device of mobile building brick kiln

A driving device and mobile technology, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc., can solve the problems of not maximizing the production of building bricks, the normal movement of the kiln body due to the deformation of the wheel shaft, and the high strength of the support seat wheel shaft. , to achieve the effect of simple structure, improved service life and widened lateral width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below through specific examples.

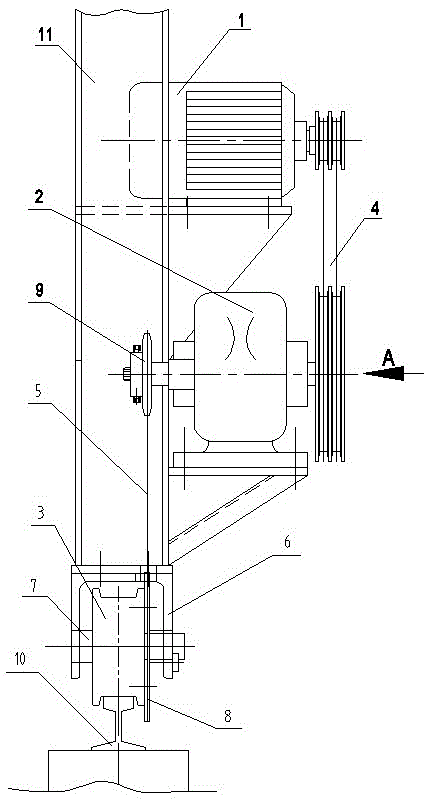

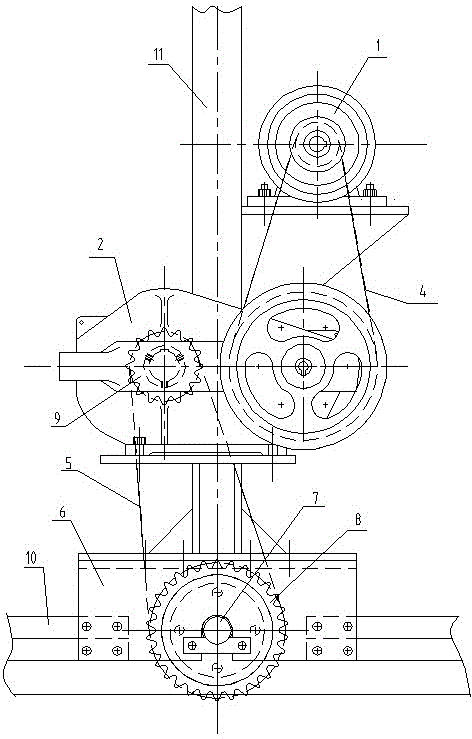

[0011] Such as figure 1 , figure 2 As shown, the driving device of the mobile building brick kiln of the present invention has a motor 1, a reduction box 2 and a walking wheel 3, the motor 1 and the reduction box 2 are installed on the outer wall of the kiln body, and the belt is passed between the motor 1 and the reduction box 2 4 Transmission of power, power transmission between the reduction box 2 and the travel wheel 3 through the chain 5, the travel wheel 3 is installed directly below the side wall of the kiln body through the support seat 6, and the wheel shaft 7 of the travel wheel 3 is fixedly connected with a driven sprocket 8. The driven sprocket 8 is connected with the driving sprocket 9 at the output shaft end of the reduction box 2 through the chain 5 . The side wall of the kiln body is mainly composed of steel girders and fiber mats installed on the steel girders. Walki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com