A spectral calibration system suitable for thermal infrared hyperspectral imager

A technology of hyperspectral imaging and spectral calibration, which is applied in the field of laser-based thermal infrared hyperspectral imager spectral calibration system, can solve the problem that there is no thermal infrared hyperspectral imager spectral calibration, and the calibration accuracy cannot meet the requirements of thermal infrared hyperspectral imager. Spectral imager spectral calibration requirements and other issues, to meet the effect of research and development requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

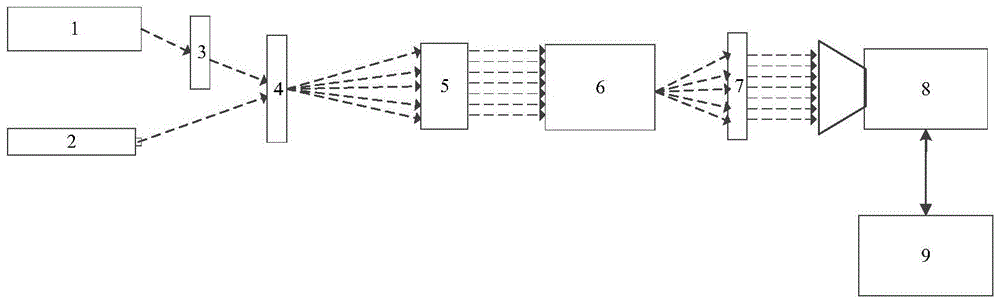

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0013] Such as figure 1 As shown, the thermal infrared hyperspectral imager 8 is installed at a predetermined location and connected to a computer 9, and the thermal infrared hyperspectral imager is controlled by the computer 9, and the thermal infrared hyperspectral imager 8 is turned on. Turn on the silicon carbide rod 1, pass through the germanium focusing mirror 3, the reflector 4, and the germanium first beam expander 5 to form parallel light, enter the iHR550 monochromator 6 to emit thermal infrared radiation with high spectral resolution, and then pass through the germanium second beam expander mirror 7, and fill the entire field of view of the thermal infrared hyperspectral imager 8, the thermal infrared hyperspectral imager 8 receives the thermal infrared radiation, the computer 9 displays the image, and the data is stored in the computer 9 at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com