Silicon-piezoresistive temperature compensation assessment method

A temperature compensation and silicon piezoresistive technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the waste of manpower, material resources, financial resources and time investment, it is difficult to quickly and accurately determine the compensation parameters, and it is impossible to realize automatic, Large-scale production and other issues can achieve the effect of accelerating technology maturity, reducing technical risks, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below.

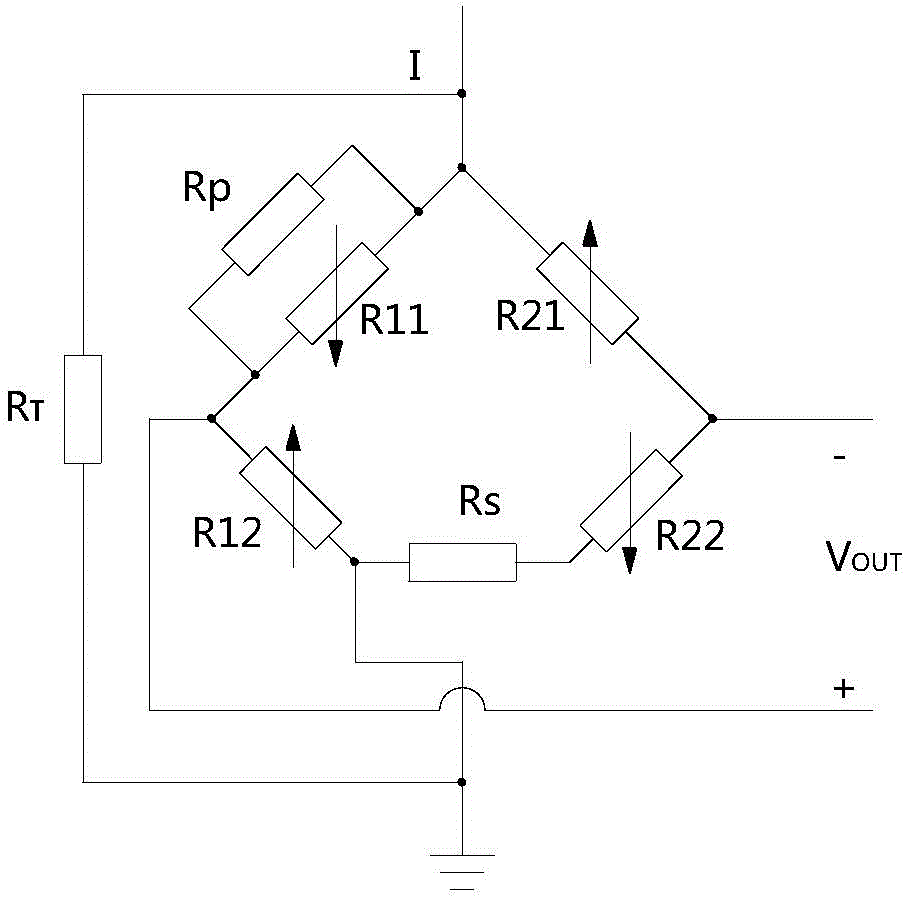

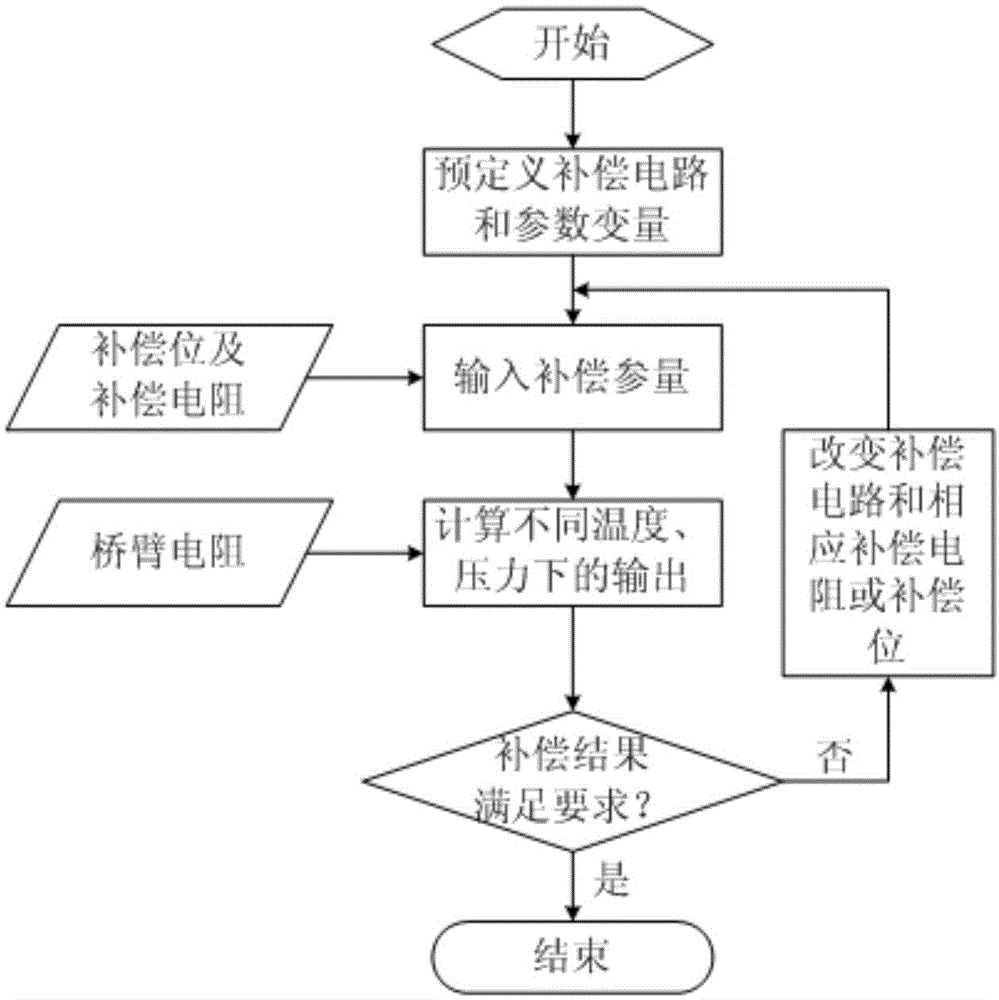

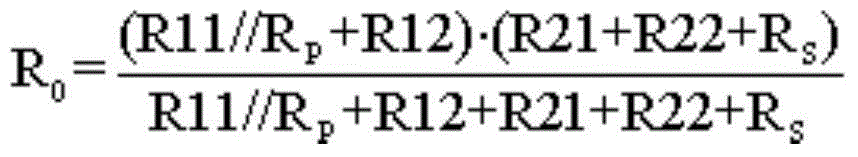

[0016] see figure 1 , the present invention takes the establishment of the temperature compensation circuit under the condition of constant current power supply as an example, in the figure, R11, R12, R21, R22 are the four bridge arm resistances of the compensated sensor Wheatstone bridge, R P Adjust the resistor, R for thermal zero drift S Adjust resistor for zero output, R τ The resistor is adjusted for thermal sensitivity drift, so the compensation circuit can compensate the sensor's zero output, full output and thermal zero drift, thermal sensitivity drift.

[0017] The resistance of the four arms of the Wheatstone bridge of the sensor is a function of temperature and pressure, and the temperature, pressure and resistance are in one-to-one correspondence.

[0018] Under a certain temperature T and pressure P, estimate figure 1 The result of the compensation circuit shown is taken as an example to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com