Transparent display, front light guiding plate and layout method of microstructural pattern of front light guiding plate

A transparent display and transparent display panel technology, which is applied in light guides, optics, instruments, etc., can solve the problems of low transmittance of light guide panels and poor display effects of transparent displays, etc., and achieve good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

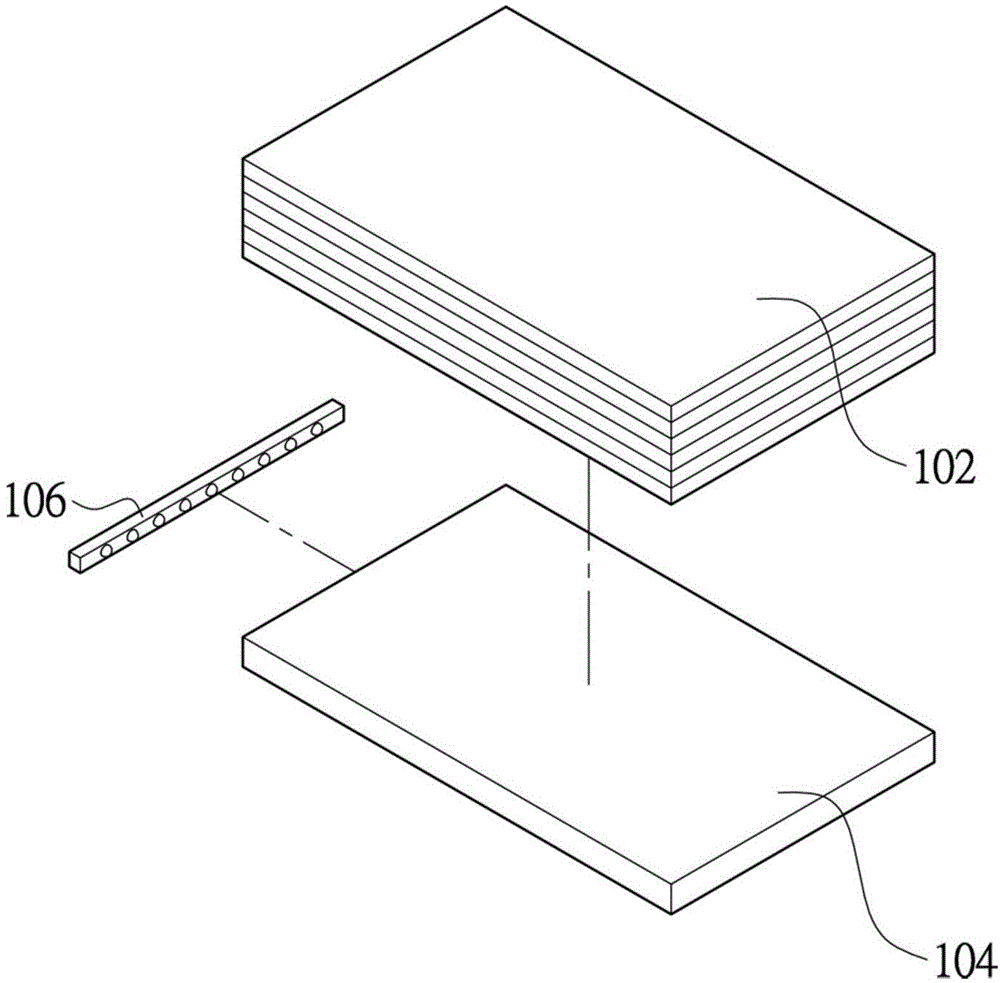

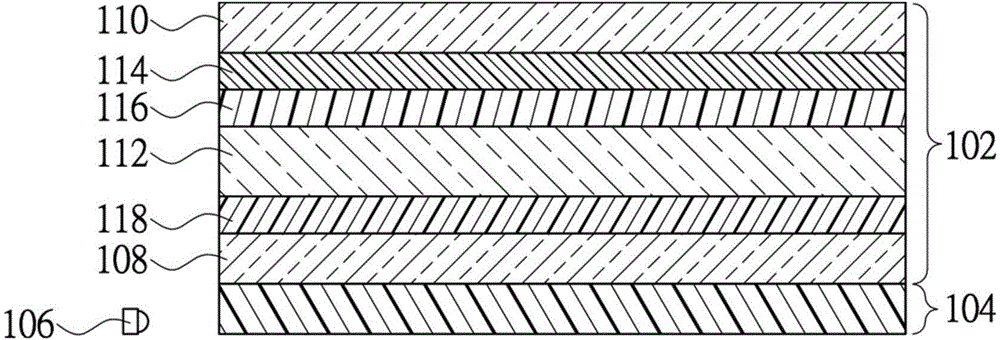

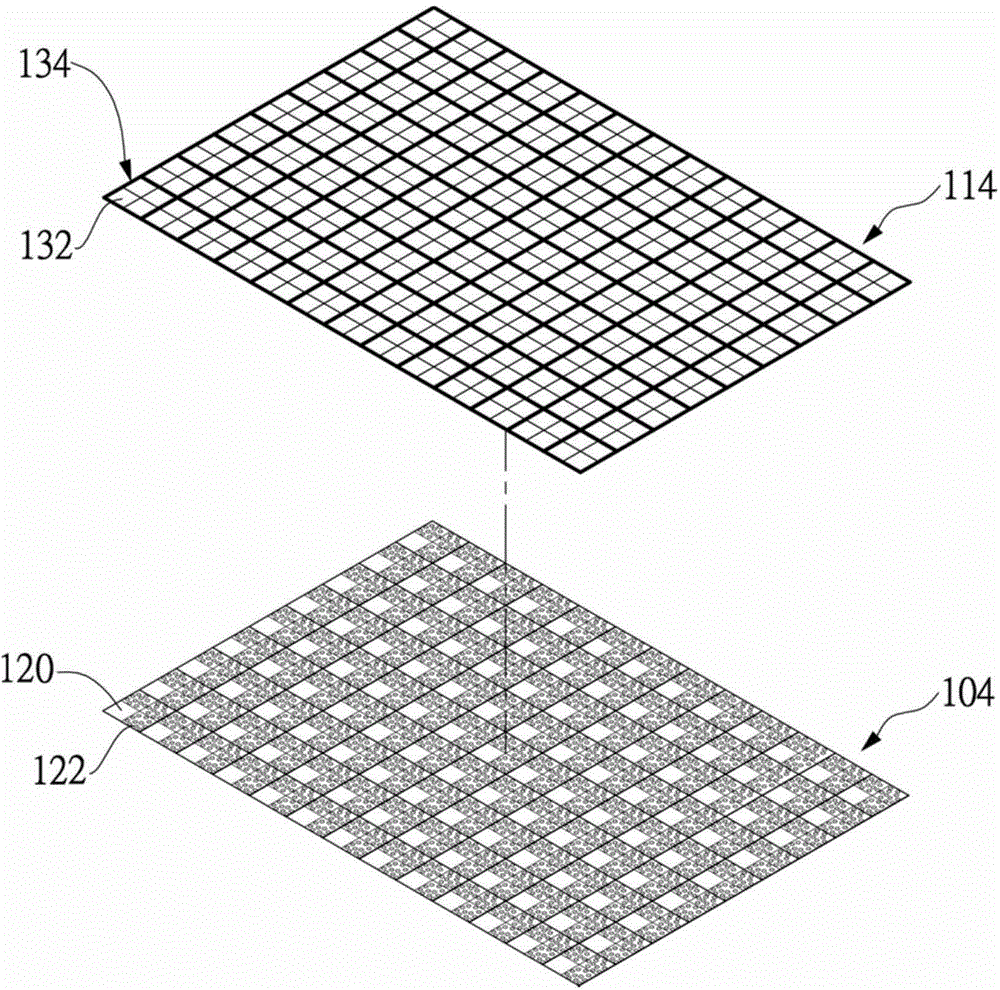

[0062] figure 1 It is a schematic diagram of the decomposition structure of the transparent display in this embodiment, figure 2 is a schematic cross-sectional view of the transparent display of this embodiment, image 3 It is a schematic diagram of the front light guide plate and the color filter layer of the transparent display in this embodiment. Please refer to figure 1 , figure 2 and image 3 , the present embodiment provides a transparent display, which includes a display panel 102, a front light guide plate 104 and a light source 106, the display panel 102 can be a liquid crystal display panel, including a first substrate 108 and a second substrate 110 opposite . A liquid crystal layer 112 is interposed between the first substrate 108 and the second substrate 110, and a first alignment layer 118 is located between the first substrate 108 and the liquid crystal layer 112, and a second alignment layer 116 is located between the second substrate 110 and the liquid c...

Embodiment 2

[0080] The transparent display of this embodiment has many similarities with the transparent display of Embodiment 1, and these similarities will not be repeated. The difference from the transparent display of Embodiment 1 is that, as Figure 6 As shown, the red sub-pixel area 126 , the green sub-pixel area 128 and the blue sub-pixel area 130 of each pixel area are arranged in a straight line and connected to the same side of the transparent area 132 .

[0081] At the same time, if Figure 7 As shown, in this embodiment, the microstructure regions 122 of each corresponding region 124 are arranged in a straight line and connected to the same side of the microstructure-free region 120 .

[0082] In addition, the layout method of the microstructure pattern on the front light guide plate of the transparent display of this embodiment has many similarities with the layout method of Embodiment 1, and these similarities will not be repeated. The difference from the layout method of Em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com