A kind of recyclable artificial turf and its preparation method

A technology of artificial turf and artificial turf, which is applied in the field of artificial turf, can solve the problems of poor water permeability of the turf system, insufficient pull-out force of the grass, and difficulty in popularization and application, so as to achieve good drainage performance, avoid pollution, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the comparison sample is as follows:

[0050] (1) Artificial turf tufting is made into a semi-finished product on a conventional base cloth, and the artificial turf used, the line spacing and needle pitch of the tufting etc. are consistent with the embodiments of the present invention;

[0051] (2) Coat the back of the semi-finished product with styrene-butadiene and PU latex according to the normal amount of glue. After drying and curing, the finished product is obtained, and drain holes are made according to the conventional requirements.

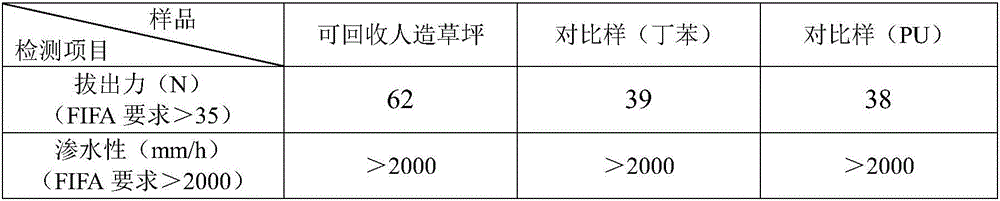

[0052] Performance testing:

[0053] The pull-out force of the grass is tested according to the ISO4919-1978 standard required by FIFA; the water permeability of the lawn is tested according to the EN12616-200 standard required by FIFA.

[0054] Embodiment is described as follows:

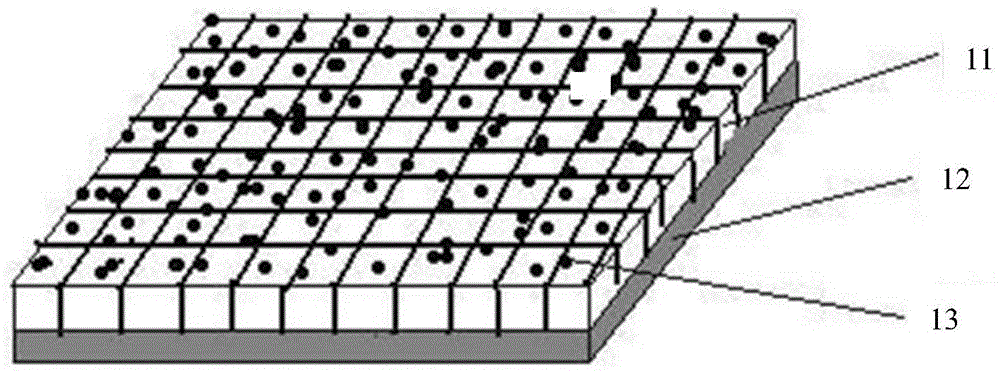

[0055] In embodiment 1-8, the selected specification of base cloth A is: 120g / m 2 Non-woven +70g / m 2 Mesh cloth (mesh siz...

Embodiment 1

[0059] According to 100g / m 2 Spread the PP hot-melt adhesive powder evenly on the base fabric A compounded by the grid cloth and the non-woven fabric, and pass through the heating device at a transmission speed of 6m / min. The heating temperature is controlled at 180-190°C. After the cloth and the non-woven fabric are bonded together, the base cloth A is obtained through cooling and rolling.

[0060] According to 60g / m 2 Spread PP hot-melt adhesive powder evenly on the base fabric B combined with grid cloth and non-woven fabric, and pass through the heating device at a transmission speed of 6m / min. The heating temperature is controlled at 180-190°C. After the cloth and the non-woven fabric are bonded together, the base cloth B is obtained through cooling and rolling.

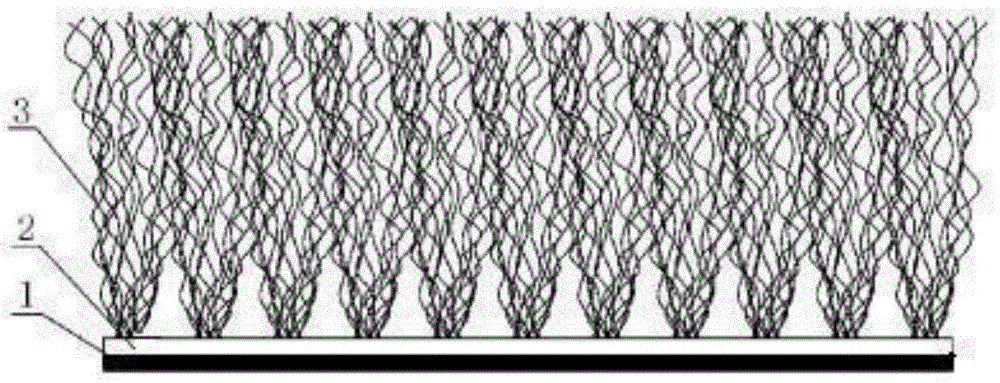

[0061] According to the corresponding needle pitch and line spacing, the artificial turf is clustered on the base fabric A (the grid surface is below) to obtain a semi-finished lawn, and the base fabric B of th...

Embodiment 2

[0063] According to 100g / m 2 Spread the PP hot-melt adhesive powder evenly on the base fabric A compounded by the non-woven fabric and the mesh cloth, pass through the heating device at a transmission speed of 5m / min, and control the heating temperature at 170-180°C. After the cloth and the non-woven fabric are bonded together, the base cloth A is obtained through cooling and rolling.

[0064] According to 60g / m 2 Spread the PP hot-melt adhesive powder evenly on the base fabric B composed of non-woven fabric and mesh cloth, pass through the heating device at a transmission speed of 5m / min, and control the heating temperature at 170-180°C. After the cloth and the non-woven fabric are bonded together, the base cloth B is obtained through cooling and rolling.

[0065] According to the corresponding needle pitch and line spacing, the artificial turf is clustered on the base fabric A (the grid surface is below) to obtain a semi-finished lawn, and the base fabric B of the same siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com