A kind of preparation method of aqueous polyurethane modified starch-based liquid mulch film

A technology of water-based polyurethane and liquid mulch, applied in botany equipment and methods, horticulture, plant protection covers, etc., can solve the problem that the product performance cannot meet the theoretical assumptions, the water absorption rate and hydrophobicity can not be guaranteed at the same time, and the polymerization reaction is difficult to be uniform and thorough To achieve good soil structure improvement and water retention, good biodegradability, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

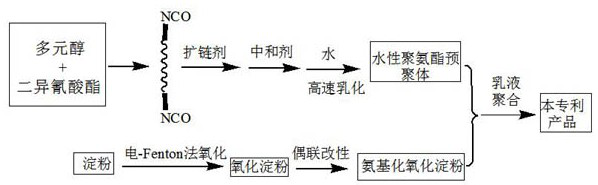

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of water-based polyurethane modified starch-based liquid mulch film, comprising the following steps:

[0050] (1) Preparation of oxidized starch dispersion

[0051] Add 490 g of water and 210 g of cornstarch to a 1 L five-necked flask at a speed of 150 r / min, stir evenly, add dilute sulfuric acid to adjust the pH to 3.0, raise the temperature to 50°C, and add 15 mL of 0.1 mol / L ferrous salt complex Combined solution (molar ratio of ferrous sulfate to sodium tartrate 1:2), insert electrodes, graphite electrode as anode, titanium electrode as cathode, calomel electrode as reference, connect to electrochemical analysis system for constant current electrolysis, current density 10 ~30 A / m 2 . Add 31.5 g of hydrogen peroxide dropwise for about 1 hour. During this period, the temperature rises rapidly. After the temperature is stable, adjust the temperature to 60°C-70°C and keep it warm for 90 minutes. Turn off the electrochemical analysis system, take o...

Embodiment 2

[0064] A preparation method of water-based polyurethane modified starch-based liquid mulch film, comprising the following steps:

[0065] (1) Preparation of oxidized starch dispersion

[0066] Add 490 g of water and 210 g of potato starch into a 1 L five-necked flask at a speed of 150 r / min, stir evenly, add dilute sulfuric acid to adjust the pH to 3.0, raise the temperature to 50°C, and add 10 mL of 0.1 mol / L ferrous salt complex Combined solution (molar ratio of ferrous sulfate to sodium citrate 1:2), insert electrodes, graphite electrode as anode, titanium electrode as cathode, calomel electrode as reference, connect to electrochemical analysis system for constant current electrolysis, current density 10~30 A / m 2 . Add 21 g of hydrogen peroxide dropwise for about 1 hour. During this period, the temperature rises rapidly. After the temperature is stable, adjust the temperature to 60°C-70°C and keep it warm for 90 minutes. Turn off the electrochemical analysis system, take ...

Embodiment 3

[0079] A preparation method of water-based polyurethane modified starch-based liquid mulch film, comprising the following steps:

[0080] (1) Preparation of oxidized starch dispersion

[0081] Add 490 g of water and 210 g of sweet potato starch into a 1 L five-necked flask, and stir at a speed of 150 r / min, then add dilute sulfuric acid to adjust the pH to 3.0, raise the temperature to 50°C, and add 12 mL of 0.1 mol / L ferrous salt complex Combined solution (molar ratio of ferrous sulfate to sodium oxalate 1:2), insert electrodes, graphite electrode as anode, titanium electrode as cathode, calomel electrode as reference, connect to electrochemical analysis system for constant current electrolysis, current density 10 ~30 A / m 2 . Add 25.2 g of hydrogen peroxide dropwise for about 1 hour. During this period, the temperature rises rapidly. After the temperature is stable, adjust the temperature to 60°C-70°C and keep it warm for 90 minutes. Turn off the electrochemical analysis sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com