Diamond drying, screening and automatic producing system

An automatic production and drying screen technology, applied in the direction of two-dimensional position/channel control, etc., can solve the problems of low production efficiency and increased costs, and achieve the effects of stable operation, extended service life and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

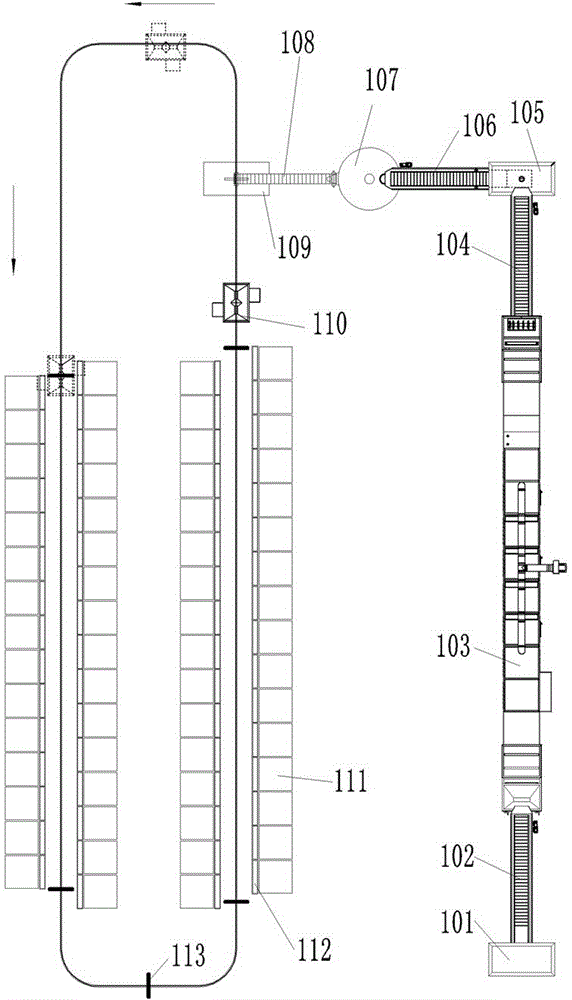

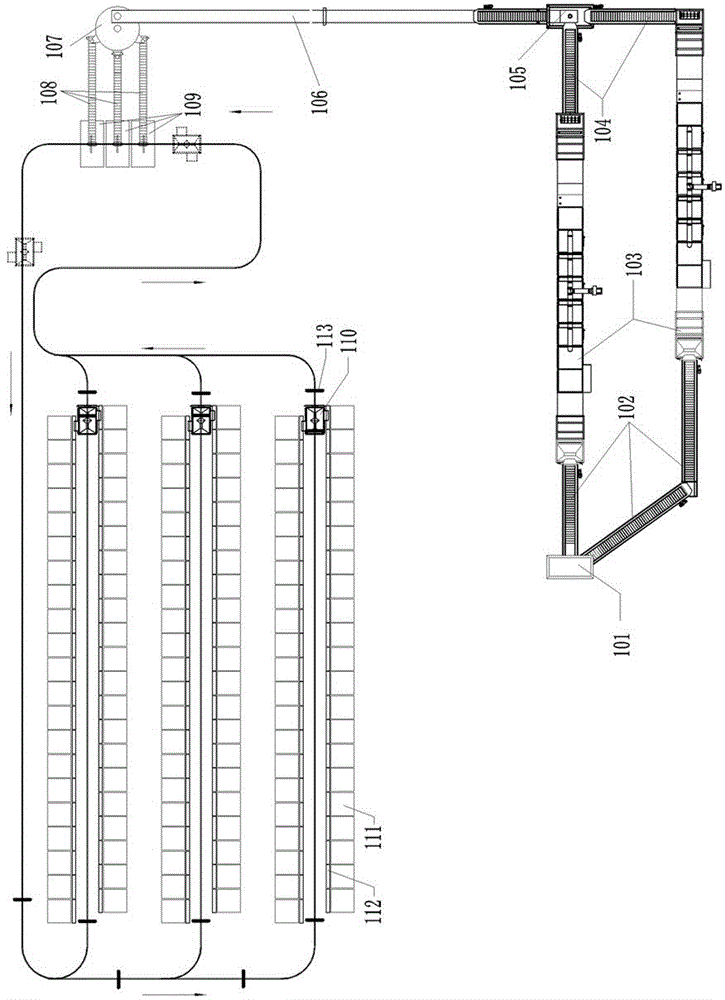

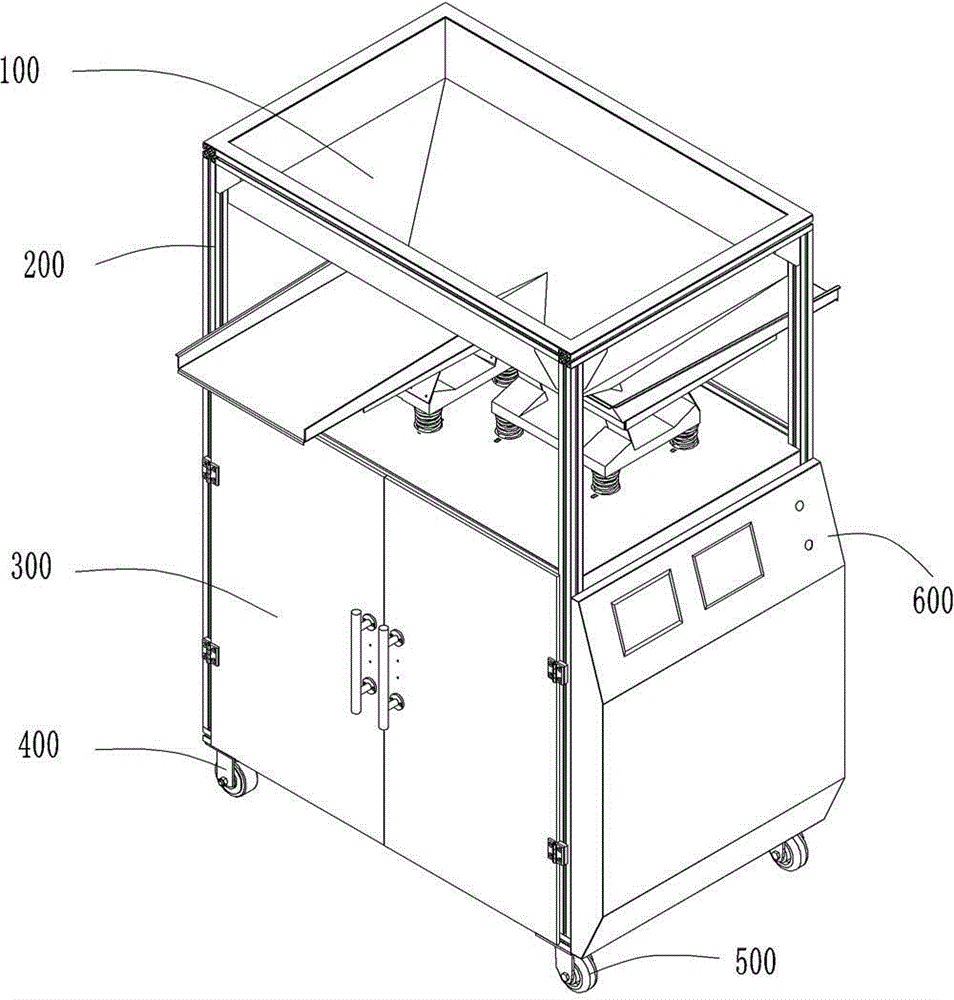

[0037] Embodiment one: see figure 1 , 2 3. An automatic production system for diamond drying and screening, including storage bins, conveyors, microwave drying equipment, hoists, screening machines, buffer bins, control systems, multiple sorting machines, and at least one AGV intelligent distribution vehicle And the track belt used to guide the walking of the AGV intelligent cloth vehicle, multiple sorting machines are arranged side by side, and the track belt is laid on the ground. Among the multiple sorting machines, the sorting machine at the first and the last A magnetic station is set near the silo of the sorting machine, and the buffer bin is provided with a vibrating feeder and an AGV intelligent cloth vehicle sensor. The track belt sensor, the driving wheel of the driving device of the AGV intelligent cloth vehicle is equipped with a magnetic station sensor. The sorting machines can be arranged in a row. In order to make full use of the space in the workshop, they ca...

Embodiment 2

[0050] Embodiment 2: the figure is not drawn, embodiment 2 is basically the same as the embodiment structure, and the similarities are not repeated, and the difference is: the feed bin of each sorting machine in the described multiple sorting machines is provided with At the magnetic station, at this time, the AGV intelligent distribution vehicle first stops in front of the silo of a sorting machine and then starts the distribution.

Embodiment 3

[0051] Embodiment 3: see figure 2 , the structure of embodiment 3 is basically the same as that of embodiment, and the similarities will not be repeated. The difference is: in order to improve production efficiency, multiple groups of drying equipment and multiple buffer bins can be used. In this embodiment, two groups of drying equipment are used , set up 3 buffer warehouses, and 3 AGV intelligent cloth vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com