Sewage treatment device with stirring roller being replaced conveniently

A sewage treatment device and stirring roller technology, which is applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the inside of the device cannot be separated from the water inlet pipe, and it is inconvenient to replace the stirring roller , low filtration efficiency of the grid mesh, etc., to achieve the effect of speeding up the relative speed, reducing labor costs, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

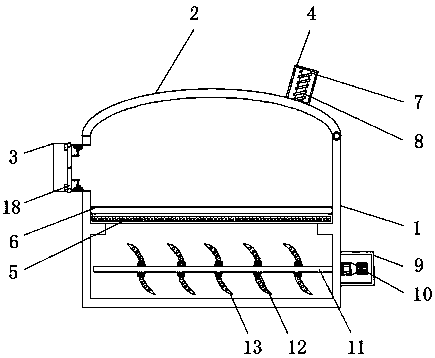

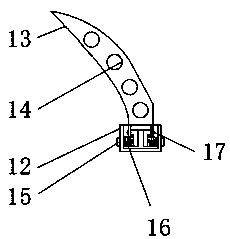

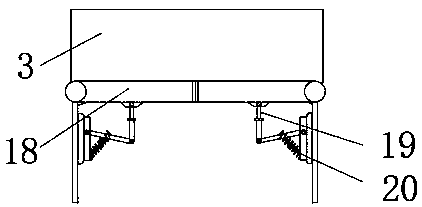

[0022] Example: refer to Figure 1-3 , the present invention provides a technical solution, a sewage treatment device that facilitates the replacement of stirring rollers, including a housing 1, a protective cover 2, a water inlet pipe 3, a protective pipe 4, a grille 5, an air gasket 6, an oxygen pipe 7, Heating wire 8, protective cover 9, motor 10, stirring shaft 11, holder 12, stirring roller 13, flow hole 14, button 15, spring 16, buckle 17, water inlet 18, reset lever 19 and return spring 20 A protective cover 2 is connected to the upper end of the housing 1, and a water inlet pipe 3 is installed on one side of the housing 1, a protective cover 9 is installed on the other side of the housing 1, and a protective tube 4 is installed on the upper end of the protective cover 2. The inside of the body 1 is provided with a grid net 5, the upper surface of the grid net 5 is equipped with an air gasket 6, the inside of the housing 1 is provided with a stirring shaft 11 close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com