Numerical control plate shearing machine with automatic alignment structure

A shearing machine and automatic technology, which is applied to machine tools, shearing devices, manufacturing tools and other directions suitable for grinding the edge of workpieces, can solve problems such as increasing the degree of waste of raw materials, increasing the cost of raw materials, and large residual area. , to save raw materials, improve alignment efficiency, and reduce waste volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

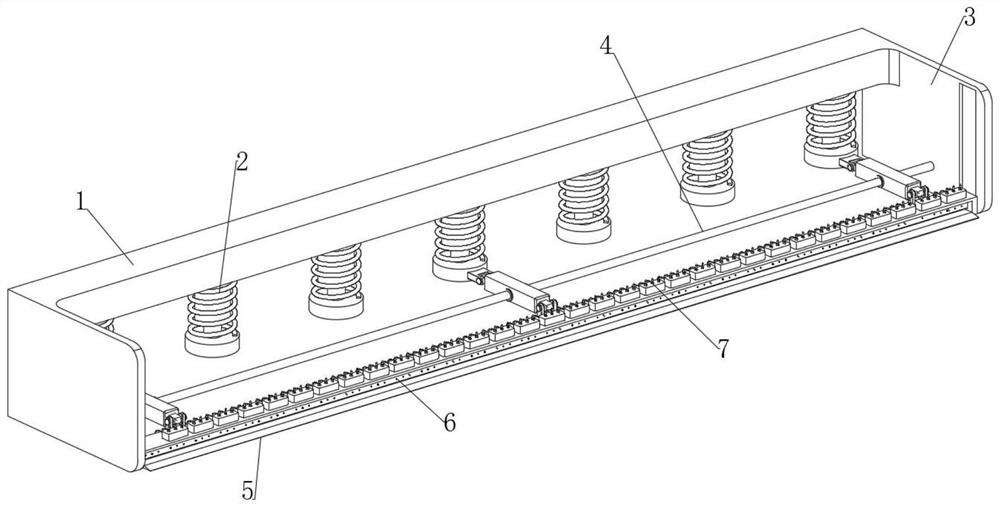

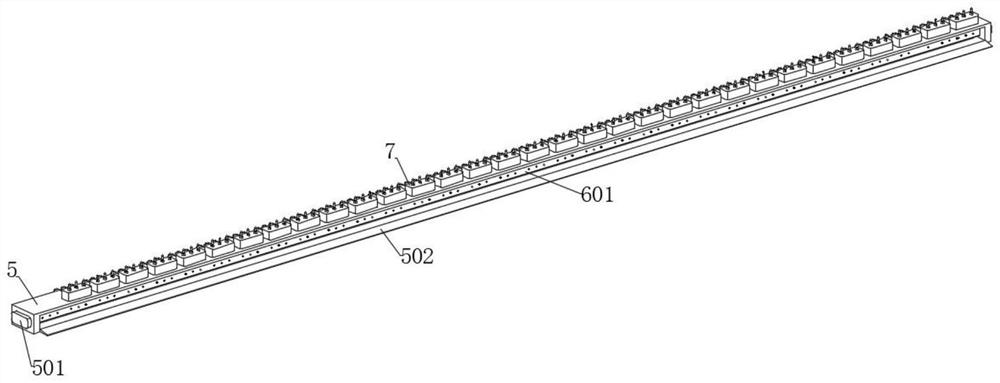

[0047] see Figure 1-10 , a numerically controlled plate shearing machine with an automatic alignment structure, comprising a clamping material fixing frame 1 installed in a numerically controlled plate shearing machine 10, a plurality of hydraulic pressure material pressing components 2 are fixedly installed on the lower end of the material pressing material fixing frame 1, and the material pressing material is fixed The left and right ends of the frame 1 are fixedly connected with a guide support plate 3, and a tilting rod drive assembly 4 located on the front side of the hydraulic pressure material assembly 2 is connected between the two guide support plates 3, and the tilt rod drive assembly 4 is connected with the hydraulic pressure material assembly. 2 are matched, the front end of the tilting rod drive assembly 4 is connected with a guide-type aligning frame 5, the guide-type aligning frame 5 is provided with a hydraulic type aligning assembly 6, and the upper end of the...

Embodiment 2

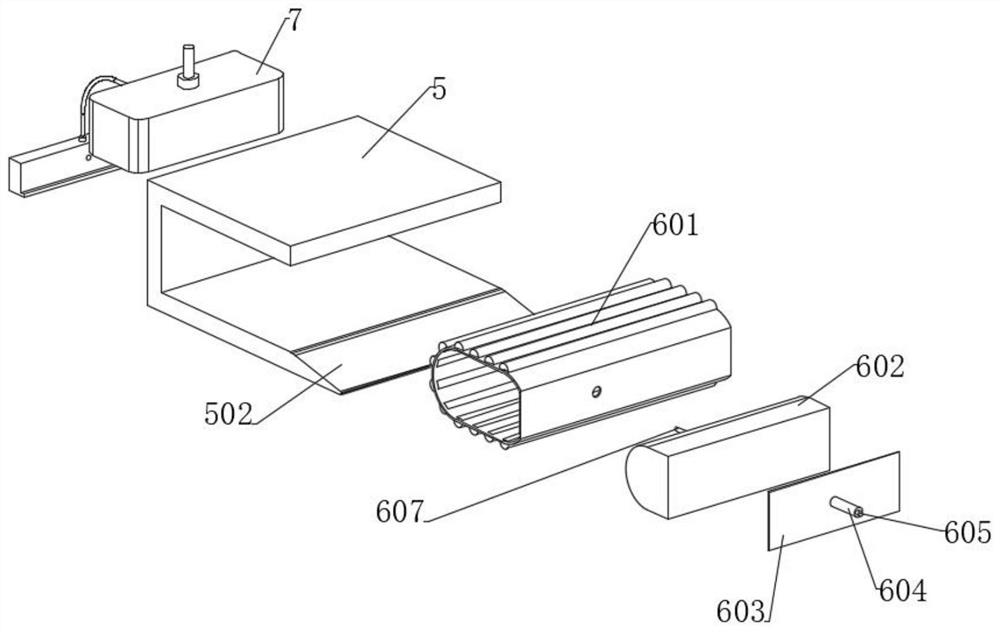

[0058] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 4 and Figure 5 , the hydraulic alignment assembly 6 includes a strip-shaped elastic bag 601, the rear inner wall of the guide-type alignment frame 5 is fixedly connected with a strip-shaped elastic bag 601, and the strip-shaped elastic bag 601 is fixedly connected with a plurality of independent hydraulic oil bags 602, The independent hydraulic oil bag 602 is fixedly connected with a plurality of anti-interference oil bags 606, and the independent hydraulic oil bag 602 is slidingly connected with a plurality of push-pack extrusion plates 603 that match the anti-interference oil bags 606, and the push-pack extrusion plates 603 is located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com