mems part and method for manufacturing

A technology of components and structures, applied in the direction of microstructure devices composed of deformable elements, electrical components, piezoelectric devices/electrostrictive devices, etc., can solve problems such as sensor performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

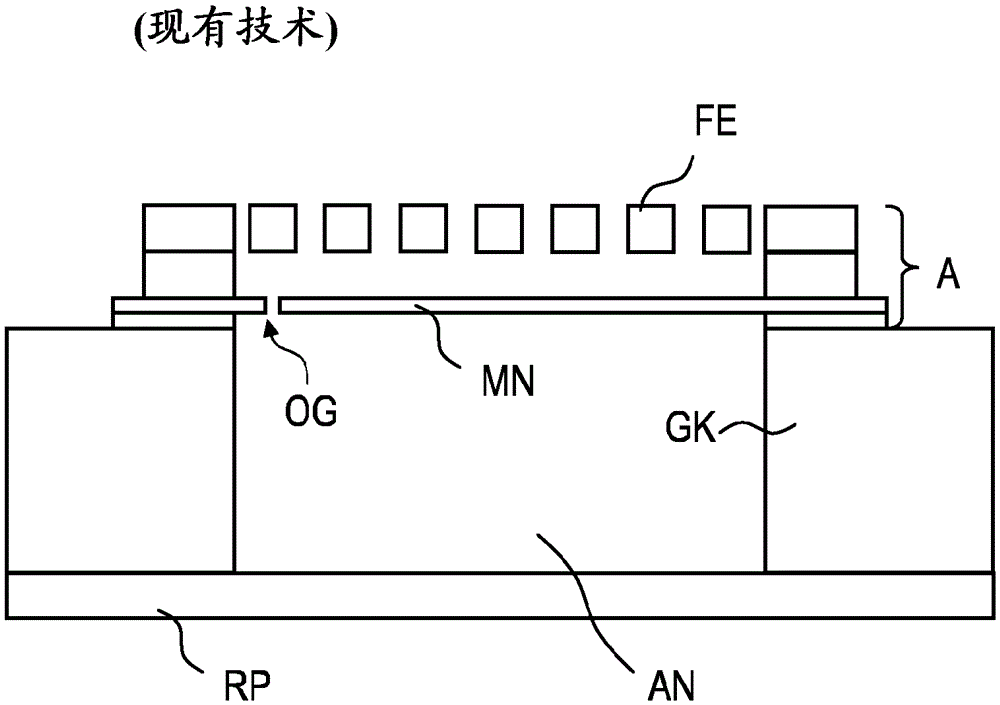

[0033] Figure 1A A MEMS microphone known from the prior art is shown in schematic section. The basic operating principle of the components is explained below on the basis of this figure. Apart from the opening and the function, the design and function of the component according to the invention are compatible with the known MEMS components described here.

[0034] The MEMS component has a crystalline base body GK, in which recesses AN are preferably structured with vertical side walls. Arranged on the upper side of the base body GK is a structure A comprising a plurality of functional layers. This construction comprises a first functional layer MN designed as a membrane, and a second functional layer designed as a fixed electrode FE. The two functional layers of configuration A cover the recess and are arranged at a distance from each other and parallel. The first functional layer MN spans the entire recess and seals it upwards. The remaining volume sealed in this way is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com