Henry steudnera tuber production line

A taro production line and taro technology, which are applied in application, food preparation, food science and other directions, can solve the problems of troublesome cutting, easy contamination of bacteria, shortened storage time of taro chips, etc., and achieve a simple and clean production process. Environmental protection, the effect of avoiding bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

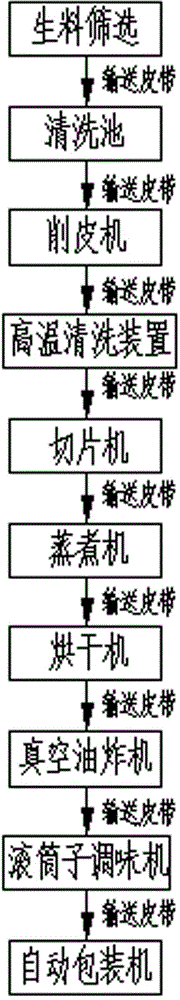

[0012] see figure 1 , a sweet potato production line, including a workshop for production, which is equipped with several independent rooms, each room is used for a piece of equipment to work, and the equipment in the front and rear rooms are connected by conveyor belts, In the first room, there are screened sweet potatoes sent from the outside of the workshop. The sweet potatoes are sent to the cleaning pool in the second room through the conveyor belt for cleaning. A conveyor belt is set beside the cleaning pool. The other end of the conveyor belt is fixed on the upper feed port of the peeler, and another conveyor belt is set up at the lower end of the peeler, and the other end of the conveyor belt is connected to a high-temperature cleaning device, which then It is connected to the slicing machine in the next room through the conveyor belt, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com