Intravenous injection dosing room and its automatic control system

An automatic control system and liquid dispensing technology, which is applied in the direction of comprehensive factory control, hypodermic injection equipment, electrical program control, etc., can solve the problems of long construction period, high investment cost, and complicated management, and achieve the effect of reducing airflow vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

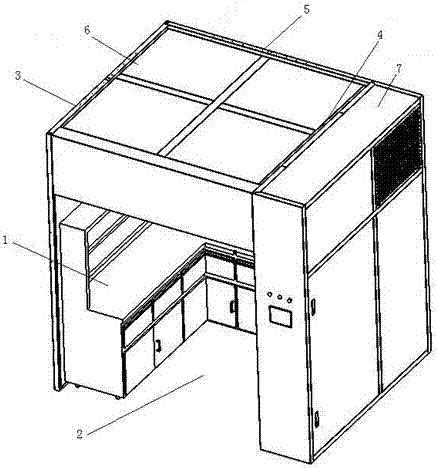

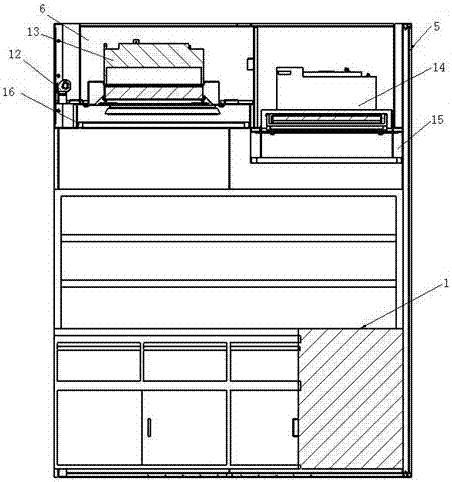

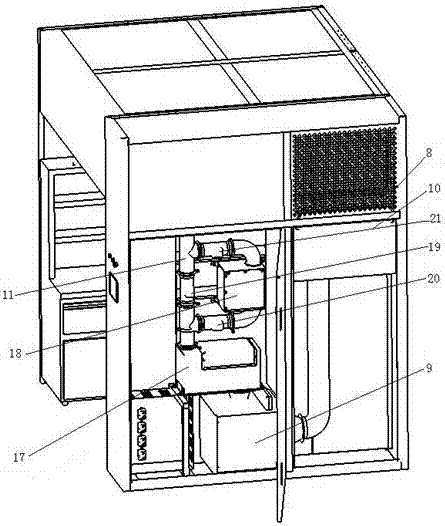

[0028] An intravenous injection dosing room, including a dosing operation room with an entrance, a dosing platform 1 and an operator activity area 2 are arranged in the dosing room, the dosing room is mainly composed of a left wall 3. In the rectangular space formed by splicing the right panel 4, the rear panel 5 and the air supply static plenum box 6 on the top, the main box 7 is installed on the side of the liquid dispensing operation room, and the fresh air collection port 8 is set on the main box 7. The blower fan 9, the filter assembly 10 and the air supply duct 11 are installed in the main chassis 7, and the filter assembly 10 is installed at the fresh air collection port 8.

[0029] The intravenous injection dosing room mainly includes a main fan 9, a cross flow fan 12, a filter assembly 10, an air supply duct 11, a first FFU f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com