Device and method for increasing washing efficiency of catalyst in reactant gas

A technology of reaction gas and washing efficiency, applied in the direction of chemical instruments and methods, separation methods, and the use of liquid separation agents, etc., can solve the problems of shortened operating cycle, insufficient gas-liquid contact, and increased system resistance, so as to reduce the cost of parking and cleaning frequency, improve the cooling effect, and the effect of uniform gas-liquid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

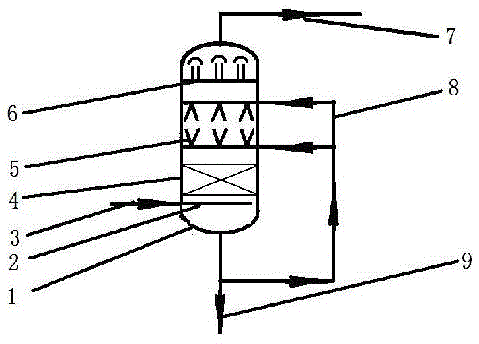

[0036] A device for improving the catalyst washing efficiency in the reaction gas. In the washing tower at the outlet of the fluidized bed reactor, two layers of reaction gas washing liquid spray layers are arranged in a square arrangement of hollow cone nozzles. The arrangement density of the nozzles is 2 nozzles / m 2 , above the spray layer, set 2 bubble cap plates of theoretical plates as demisters, set 6 theoretical plates of grid packing under the spray layer of reaction gas washing liquid and above the inlet of reaction gas, and set dendritic porous at the inlet of reaction gas Type sparger, after being sprayed and washed by the nozzle of the washing tower, the removal rate of the catalyst fine powder entrained in the reaction gas reaches 99.8%, the washing tower and subsequent systems are not blocked, the separation efficiency of the separation tower, the heat transfer effect of the heat exchanger, the system resistance, The load of the device remains unchanged, and the ...

Embodiment 2

[0039] A device for improving the catalyst washing efficiency in the reaction gas. In the washing tower at the outlet of the fluidized bed reactor, 8 layers of reaction gas washing liquid spray layers composed of solid cone nozzles arranged in an equilateral triangle are arranged. The arrangement density of the nozzles is 1 nozzle / m 2 , a sieve plate with a theoretical plate is set above the spray layer as a demister, a Raschig ring packing with 10 theoretical plates is set under the spray layer of the reaction gas washing liquid and above the inlet of the reaction gas, and double rows of blades are set at the inlet of the reaction gas Type distributor, the removal rate of catalyst fine powder entrained in the reaction gas after spraying and washing by the nozzle of the washing tower reaches 99.6%, the washing tower and subsequent systems are not blocked, the separation efficiency of the separation tower, the heat transfer effect of the heat exchanger, the system resistance, an...

Embodiment 3

[0042] A device for improving the catalyst washing efficiency in the reaction gas. In the washing tower at the outlet of the fluidized bed reactor, a layer of reaction gas washing liquid spray layer composed of spiral nozzles arranged in a rectangle is arranged. The arrangement density of the nozzles is 4 nozzles / m 2 , above the spray layer, set one piece of theoretical plate packing as a demister, set two theoretical plates of regular wire mesh corrugated packing under the reaction gas washing liquid spray layer, and above the reaction gas inlet, and set the reaction gas inlet with a semicircular tube type Distributor, after being sprayed and washed by the nozzle of the washing tower, the removal rate of the catalyst fine powder entrained in the reaction gas reaches 99.7%, the washing tower and subsequent systems are not blocked, the separation efficiency of the separation tower, the heat transfer effect of the heat exchanger, the system resistance, and the device load Keepin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com