Bearing washing machine

A bearing cleaning and cleaning device technology, which is applied in the field of cleaning equipment and bearing cleaning machines, can solve problems such as ineffective cleaning of bearings, clogging of the cleaning system, unsatisfactory cleaning effect, etc., to avoid abnormal damage to parts and ensure quality And the use of precision, ideal effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

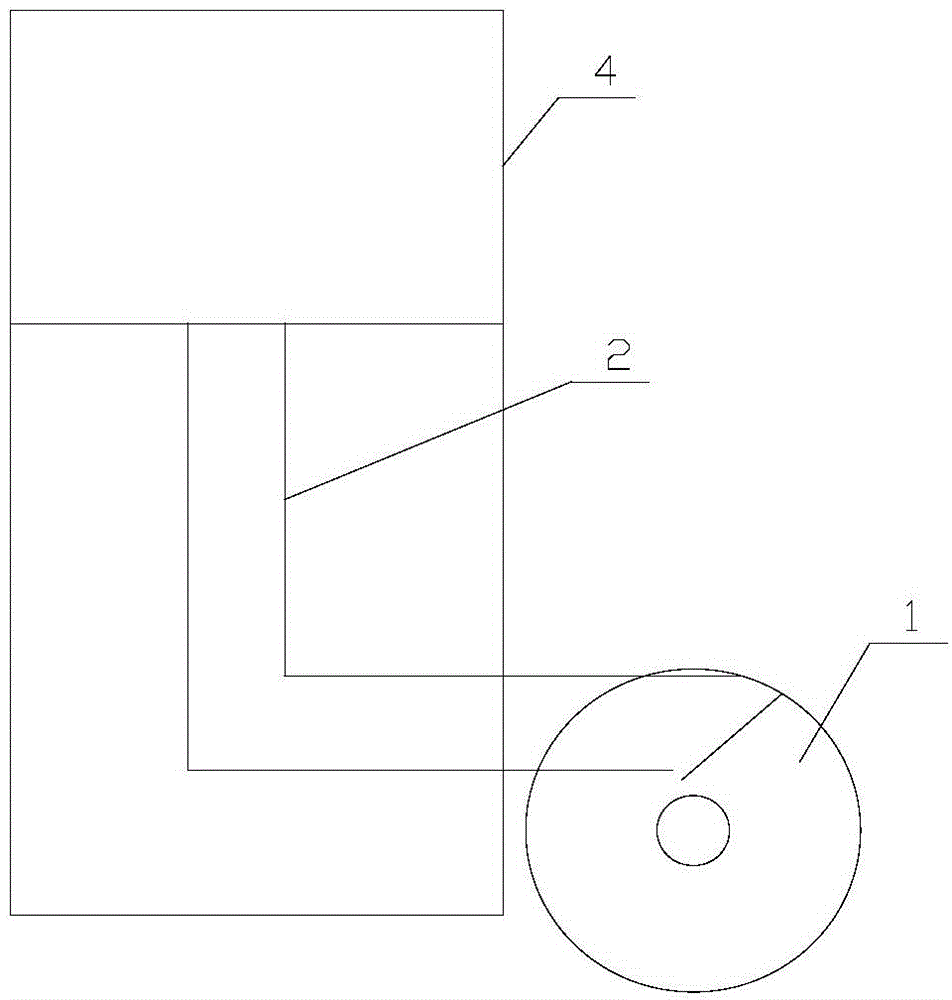

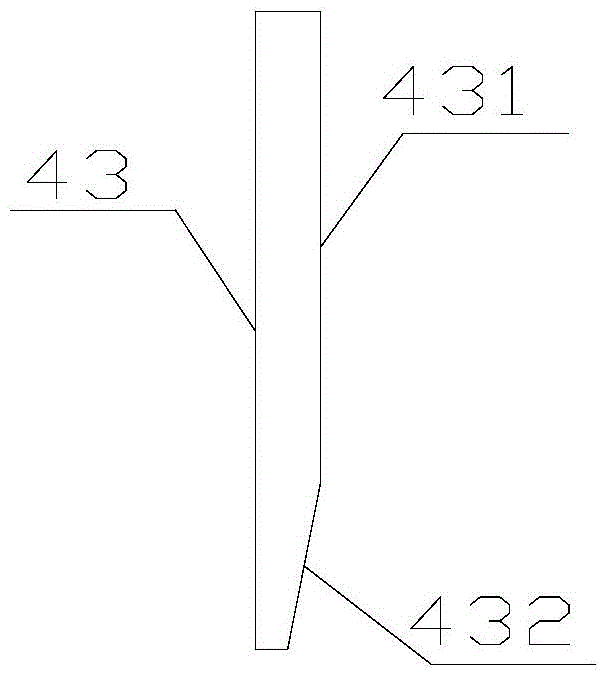

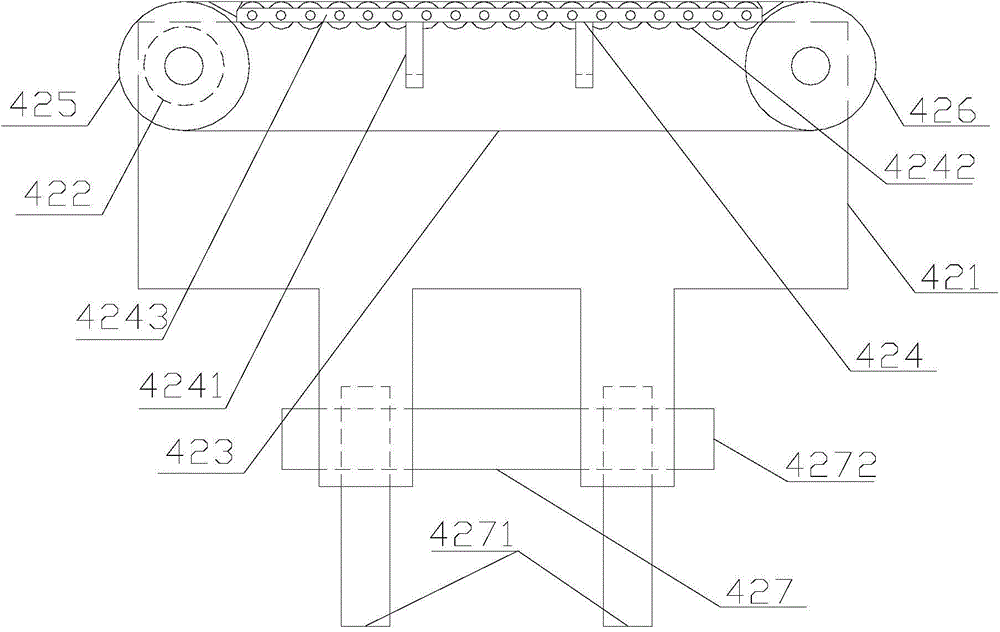

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6, a bearing cleaning machine of the present invention, comprising a feeding tray 1, a feeding track 2 and a cleaning device 4, the output end of the feeding tray 1 is connected to the input end of the feeding track 2, and the output end of the feeding track 2 is connected to the cleaning device 4 connection, the feeding track 2 includes a third motor 21, a first gear 22, a second gear 23, a rotating shaft 24, a horizontal feeding mechanism 25, a longitudinal feeding mechanism 26, a connecting chute 27 and a frame body 28, and the frame The platform of body 28 is provided with the 3rd motor 21, rotating shaft 24, horizontal feeding mechanism 25, vertical feeding mechanism 26 and connecting chute 27, and the output end of described horizontal feeding mechanism 25 is connected with vertical feeding mechanism 26 by connecting chute 27. The input end of described third motor 21 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com