Anti-slip tooth design applicable to high-hardness metal sectional material stretching and straightening

A technology of metal profiles and anti-slip teeth, which is applied in the design of anti-slip teeth on the jaws of stretching machines, and in the field of anti-slip teeth design, can solve problems such as too deep bite, inability to bite in, and broken ends, etc., to achieve moderate bite depth and avoid stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

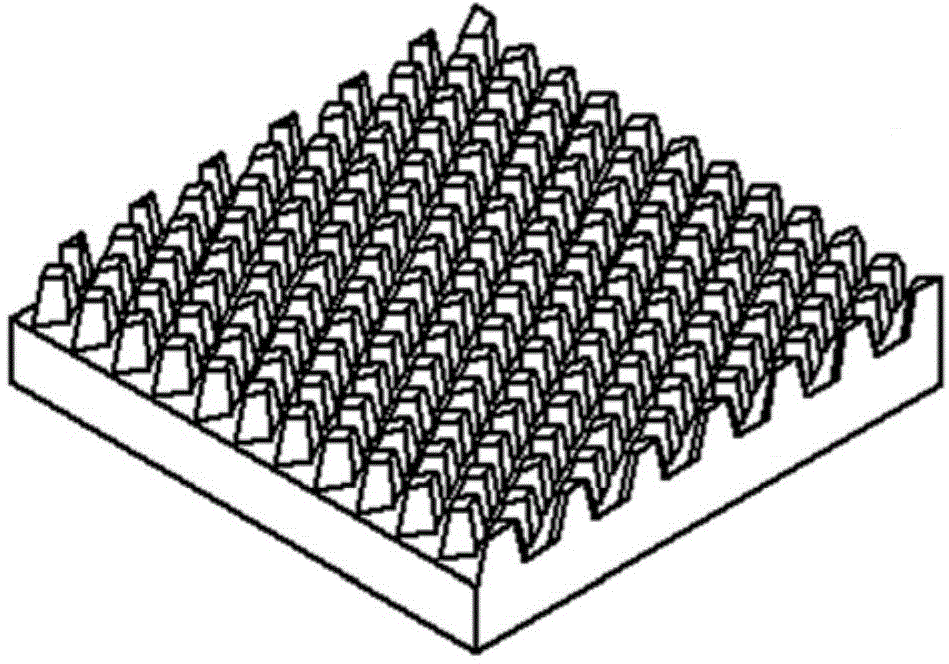

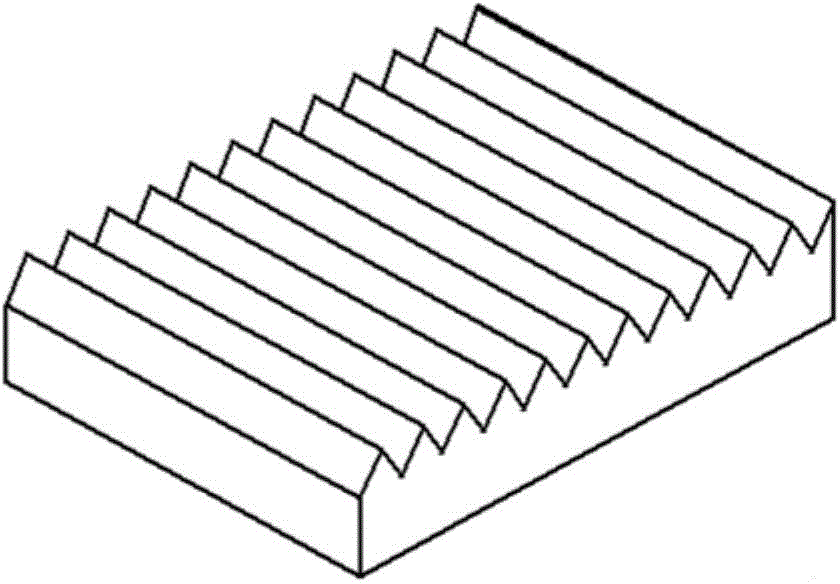

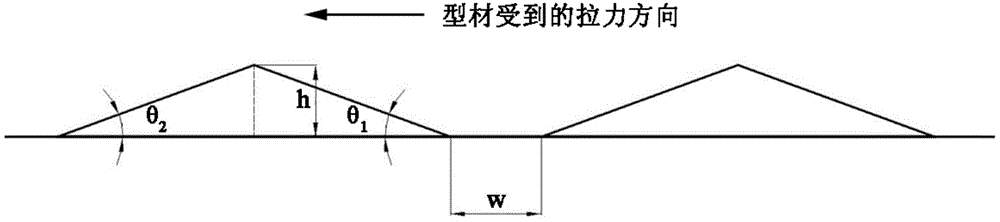

[0019] When stretching and straightening ultra-high-strength rare earth magnesium alloy extruded sheets, the convex nail type anti-skid teeth ( Figure 1(a) ) cannot avoid slipping, while the usual triangular-section straight teeth ( Figure 1(b) ) would cause broken ends, so the anti-skid teeth were redesigned. The size of the plate to be straightened is 300mm×25mm×10000mm. The parameters of the designed tooth shape are as follows: tooth height h=2mm, front bottom angle θ 1 = Rear base angle θ 2 =20°, the platform width between teeth w=5mm, the tooth profile is as follows image 3 shown. After the anti-skid teeth are processed, the surface layer of the jaw where the anti-skid teeth are located is quenched to improve its hardness and wear resistance. At the same time, remove the metal debris between the anti-slip teeth in time to avoid excessive accumulation of debris that will paste the anti-slip teeth and cause slippage.

[0020] practice shows that, image 3 The anti-...

Embodiment 2

[0022] When stretching and straightening the high-strength rare-earth magnesium alloy rectangular cross-section square bar with a specification of 210mm×95mm×14000mm, the usual anti-skid teeth cannot effectively avoid slipping and broken ends, so the anti-skid teeth were redesigned. The parameters of the designed tooth shape are as follows: tooth height h=5mm, front bottom angle θ 1 =30°, back bottom angle θ 2 =100°, the platform width between teeth w=0, the tooth profile is as follows Figure 4 shown. After the anti-skid teeth are processed, the surface layer of the jaw where the anti-skid teeth are located is quenched to improve its hardness and wear resistance. At the same time, remove the metal debris between the anti-slip teeth in time to avoid excessive accumulation of debris that will paste the anti-slip teeth and cause slippage.

[0023] After practice, Figure 4 The anti-skid teeth shown are effective in preventing slipping and end breaks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com