Chip breaking ball-end milling cutter

A ball-end milling cutter and chip breaking technology, applied in milling cutters, milling cutting inserts, milling machine equipment, etc., can solve the problems that the workpiece, the tool itself and the operator pose a danger, affect the normal progress of processing, etc., to improve waterproof and durable. Corrosion performance, improved surface finish, damage avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

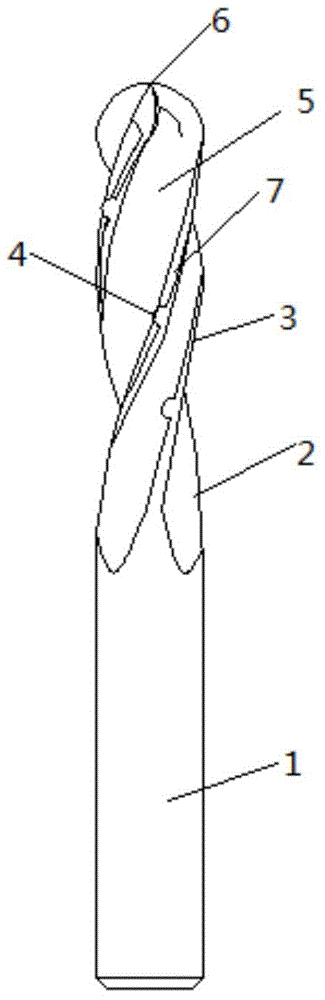

[0011] refer to figure 1 , a chip breaking ball end milling cutter, comprising a tool holder 1 and a cutting portion 2, the cutting portion 2 includes a circular cutting edge 6 on the end face of the cutting portion, and a helical cutting edge is also provided on the peripheral surface of the cutting portion 2 Edge 3, the arc-shaped cutting edge 6 is connected with the helical cutting edge 3, and a chip removal groove 5 is formed between the helical cutting edges 3, and a spiral shape extending toward the front end of the cutter head is formed between the chip removal grooves. The protruding ridge 7 is provided with a chip breaking port 4 for chip breaking.

[0012] The total axial length of the tool handle 1 and the cutting part 2 is 50mm-100mm.

[0013] The arc angle of the arc-shaped cutting edge 6 is 185°-205°.

[0014] The cutting part 2 is also coated with a silicon coating; the performance of waterproof and corrosion resistance of the milling cutter is improved, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com