Material loading and unloading device for bearing ring and method for realizing material loading and unloading

A bearing ring and blanking technology, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., can solve the problems of low production efficiency, achieve simple adjustment, save time, and improve labor efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

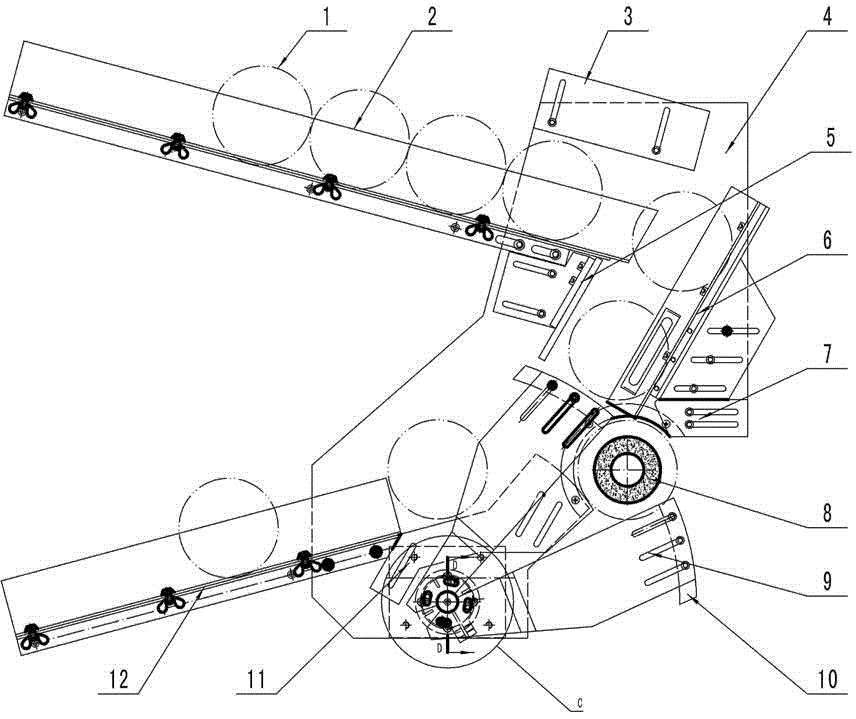

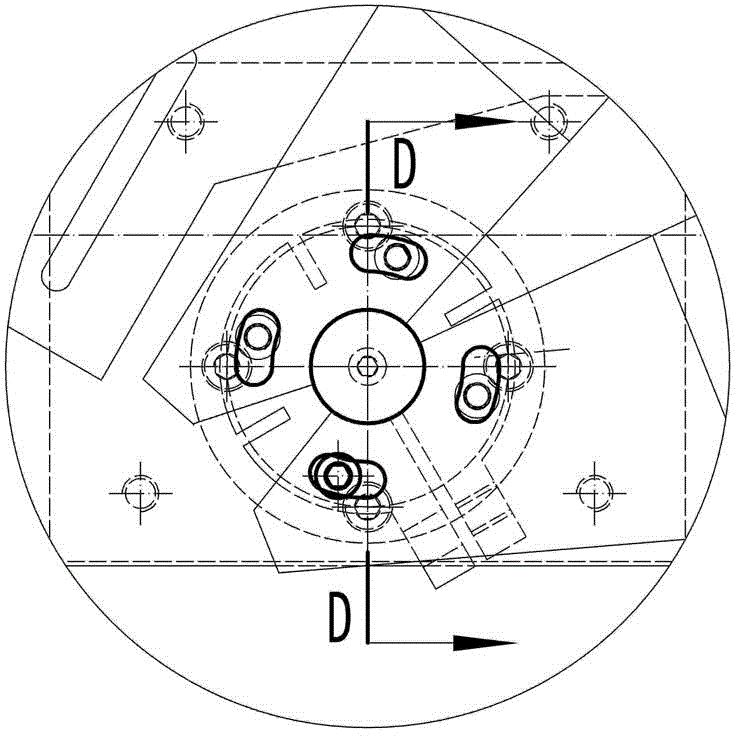

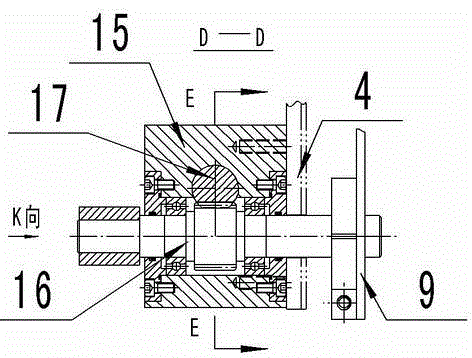

[0021] As shown in the figure, the loading and unloading device for the bearing ring includes a feeding channel 2 , a panel 4 , a left baffle 5 , a right baffle 6 and a feeding channel 12 . The upper material channel 2 is fixed on the upper part of the panel 4, the lower material channel 12 is located below the panel 4, the left baffle plate 5 and the right baffle plate 6 are relatively fixed on the panel 4, and an upper baffle is set above the upper material channel 2 on the panel 4 plate 3. The right side of the blanking channel 12 is provided with a blanking support plate 11 corresponding to the blanking channel formed by the left baffle plate 5 and the right baffle plate 6 , and an adjusting plate 7 is fixedly connected to the bottom of the panel 4 . The adjusting plate 7 can adjust its position relative to the panel 4 to adapt to bearing rings of different sizes and prevent the bearing ring from falling from the position of the adjusting plate 7 . A fork-type rotating me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com