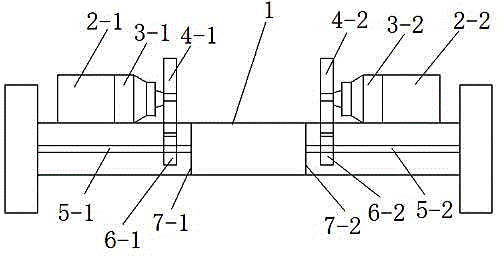

Double-motor-driving electric vehicle rear axle

A dual-motor drive, electric vehicle technology, used in electric power units, power units, vehicle components, etc., can solve the problems of unrealistic rear axle space design, easy damage to motors, etc., to improve power and torque output characteristics, and facilitate processing. , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to better understand and implement the technical solutions of the present invention, some embodiments of the present invention are provided here. These examples are for better explaining the technical solutions of the present invention, and do not constitute any form of limitation to the present invention.

[0008] Dual-motor driven electric vehicle rear axle: dual-motor driven electric vehicle rear axle, including two semi-shafts arranged on the rear axle, two motors are arranged on the rear axle, and the power output of the two motors is directly Or indirectly connect and drive the two semi-shafts on the rear axle, the two motors are arranged on both sides of the middle part of the rear axle, the two motors are the same, the axes of the two motors are on a straight line, the The output of each motor is directly or indirectly connected to the driving gear, and the passive gears meshing with the driving gear are respectively fixed on the two semi-shafts, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com