Online assembling ageing and integrating line of LED product and assembling ageing processing thereof

An assembly line and integrated line technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve problems such as occupying a large working area, increasing production expenditure of enterprises, and human body electrostatic hazards, so as to improve efficiency and work Efficiency, reduced labor costs, and reduced operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

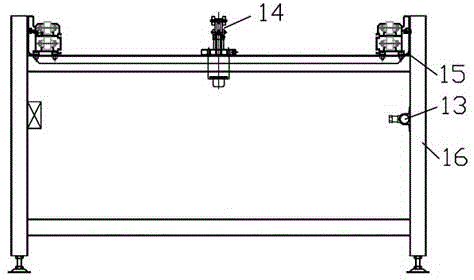

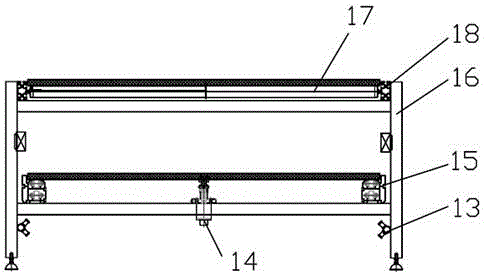

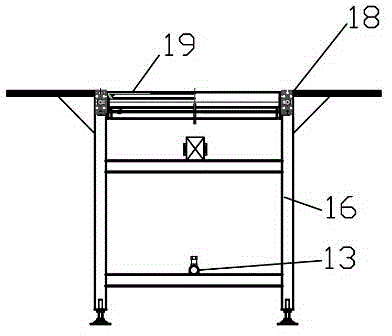

[0035] Such as Figure 1-7 As shown, an online assembly and aging integrated line for LED products, the integrated line mainly includes a double-speed assembly line 1, a lifting mechanism 5, a single-station mechanism 4, a jacking translation mechanism 6, a double-speed assembly sub-line 12, a parallel shifting Planting mechanism, transition line mechanism 8, reciprocating lifting mechanism 95, aging line 10 and packaging line 11.

[0036] The double-speed assembly line 1 includes upper and lower layers that both adopt double-speed guide rails 15 for transmission. The blocker 14 is connected, and the bottom side of the tripod 16 of the double-speed assembly line 1 is provided with an air pipe 13. The assembly tooling plate on the upper layer of the double-speed assembly line 1 is used for the assembly of the parts of the LED product. into the aging tooling board, and the empty assembling tooling board is sent to the lifting mechanism 5 at the tail end.

[0037] The lifting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com