Magnetic belt type automatic plate stacker

A technology of magnetic belt and stacker, which is applied in the field of mechanical equipment, can solve the problems of high manual operation cost and error-prone counting, and achieve the effect of outstanding stacking effect, high degree of automation, and wide specification range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

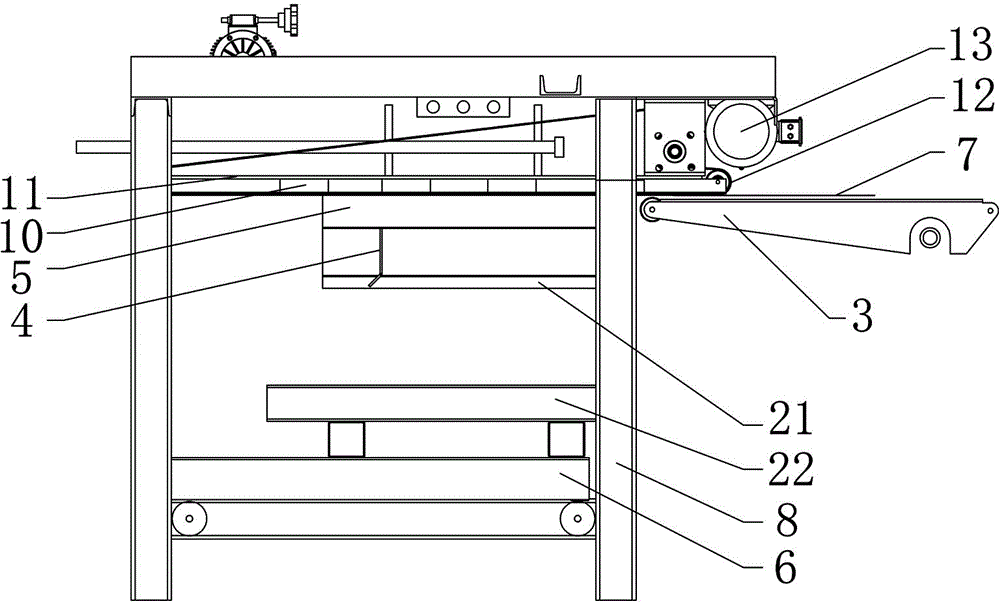

[0017] Refer to attached figure 1 , the present invention is a magnetic belt automatic stacker, mainly comprising a frame 8 and an electromagnetic belt set on the upper side and an automatic stacking set on the lower side. The electromagnetic belt group is used to complete the adsorption, transportation and lowering of the steel plates 7, and the automatic stacking group is used to complete the neat stacking of the lowered steel plates 7.

[0018] Specifically, the electromagnetic belt set includes an electromagnet mounting frame 11, a conveyor belt 12, and a motor 13. Some electromagnets 10 with an initial suction force of 100KG are regularly installed on the electromagnet mounting frame 11. The upper end faces of these electromagnets 10 are mounting surfaces. The conveying direction is closely arranged on the electromagnet mounting frame 11, and the lower end surface is an adsorption surface, which is directly in contact with the conveying belt 12 to form a magnetic belt. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com