A kind of hydrophilic ultra-macroporous polymer microsphere and preparation method thereof

A polymerization method and linear polymer technology, applied in the field of hydrophilic ultra-macroporous polymer microspheres and their preparation, can solve the problems of poor strength of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

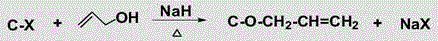

Method used

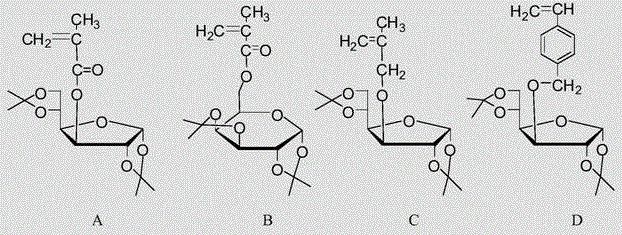

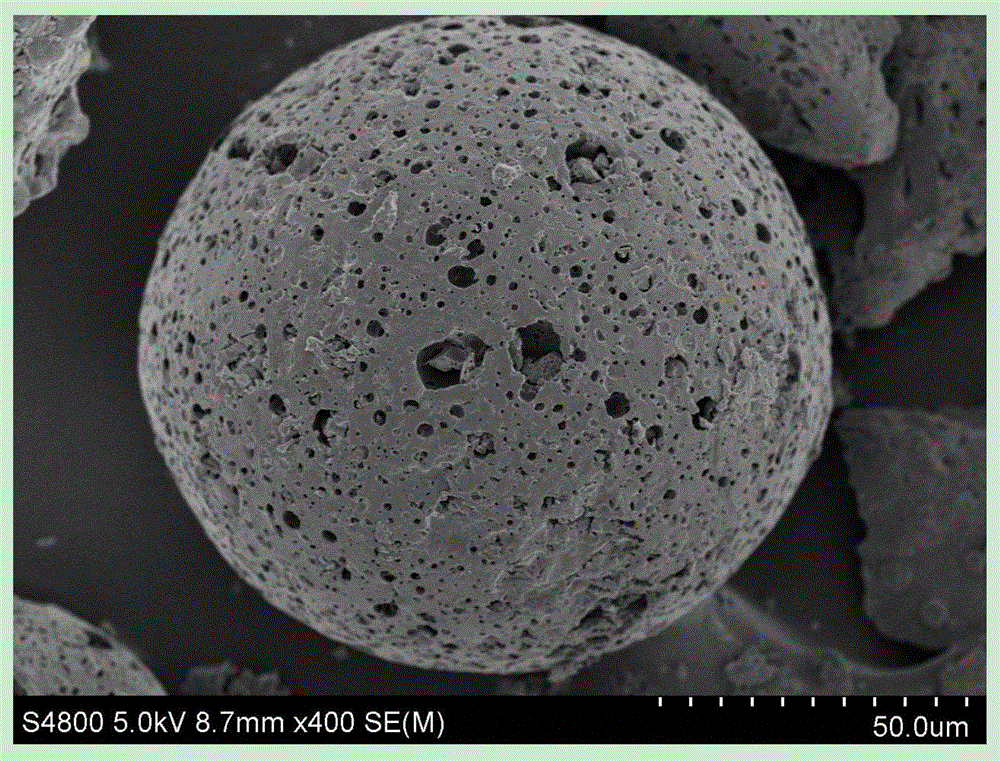

Image

Examples

Embodiment 1

[0058] 1) Synthesis of poly 3-O-methacryloyl-diacetone-D-galactose (PMDAGal) by ATRP reaction

[0059] Add a stirring bar to the Schlenk bottle at room temperature, then add cuprous bromide (6.45mg), N,N,N,N',N'-pentamethyldiethylenetriamine (PMDETA) (9.0mg ), 3-O-methacryloyl-diacetone-D-galactose (MDAGal) (1.52g) and 4ml toluene, after three cycles of liquid nitrogen freezing-pumping-gassing-thawing to remove oxygen. Finally, the initiator 1-bromoethylbenzene (18.3mg) was added, reacted at 60°C for 4h, dissolved the reaction product with chloroform, diluted the reaction product, and removed the catalyst through an aluminum oxide column. The resulting colorless solution was precipitated twice with methanol, filtered with suction at room temperature, and dried in vacuo to obtain 0.79 g of PMDAGal, whose molecular weight Mn=6835 was detected by gel permeation chromatography (GPC).

[0060] 2) Synthesis of poly 3-O-methacryl-diacetone-D-galactose-polystyrene block copolymer (PM...

Embodiment 2

[0068] 1) Synthesis of PMDAGlu by ATRP reaction

[0069] Add a stirring bar to the Schlenk bottle at room temperature, then add cuprous chloride (3.2mg), PMDETA (7.1mg), MDAGlu (0.98g) and 3ml chlorobenzene in sequence, and go through three liquid nitrogen freezing-pumping-gassing -Thaw cycle process, remove oxygen. Finally, the initiator 2-bromoisobutyrate ethyl ester (30.4 mg) was added, reacted at 50°C for 4 hours, dissolved the reaction product with tetrahydrofuran, diluted the reaction product, and removed the catalyst through an aluminum oxide column. The resulting colorless solution was precipitated twice with methanol, filtered with suction at room temperature, and dried in vacuo to obtain 0.59 g of PMDAGlu, whose molecular weight Mn=4631 was detected by gel permeation chromatography (GPC).

[0070] 2) Synthesis of PMDAGlu-PS by ATRP reaction

[0071] Add a stirring bar to the Schlenk bottle at room temperature, then add cuprous bromide (14.6mg), PMDETA (22.8mg), sty...

Embodiment 3

[0078] 1) Synthesis of poly 3-O-methallyl-diacetone-D-glucose (PMAlDAGlu) by AGET-ATRP reaction

[0079] At room temperature, in a 100ml three-neck flask with a stopper, add 4ml of profloxacin, MAlDAGlu (1.42g), FeCl3 (8.4mg), triphenylphosphine (35.4mg), methyl 2-bromopropionate (75.3mg), and stir Make it evenly mixed, pass nitrogen gas to remove oxygen for 10 minutes, add reducing agent ascorbic acid (7.9mg), under nitrogen protection, react at 55°C for 2h, dissolve the reaction product with tetrahydrofuran, precipitate with methanol twice, suction filter at room temperature, and vacuum dry , to obtain 0.49gPMDAGal, the molecular weight Mn=1356 detected by gel permeation chromatography (GPC).

[0080] 2) Synthesis of poly 3-O-methallyl-diacetone-D-glucose-polystyrene block copolymer (PMAlDAGlu-PS) by AGET-ATRP reaction

[0081] Add styrene (2.36g), FeCl 3 (10.8mg), triphenylphosphine (44.96mg), PMAlDAGlu (0.26g), stir to mix evenly, deoxygenate with nitrogen gas for 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com