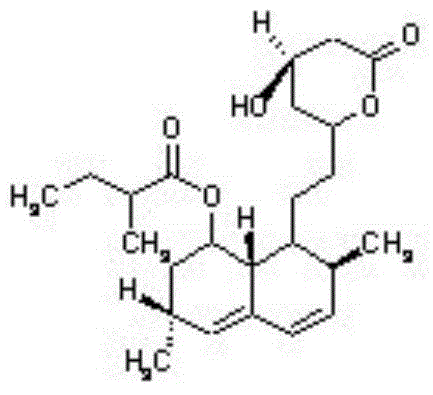

Millet spore culture medium for fermentation production of lovastatin and preparation method of millet spore

A culture medium preparation, lovastatin technology, applied in the direction of using spores, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of high labor intensity, unfavorable large-scale production, inconvenient operation, etc., to reduce contamination The effect of reducing the chance of bacteria, reducing labor intensity, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the process of culturing and preparing rice spores is described by taking the water increase amount of millet reaching 20% as an example, including the following steps:

[0038] (1) Weigh 200g (W1) of millet, 60ml of water, and 3g of corn steep liquor, mix the corn steep liquor and water evenly and pour into a pot to heat, then pour the millet into it and stir-fry until the weight of the millet reaches 250g and take out ;

[0039] (2) Steam the fried millet at 100°C for 15 minutes, and then rub it up;

[0040] (3) after the steamed millet is aired to 240g (W2), the millet is divided into shake bottles, 25g / bottle;

[0041] (4) steam the shake flask that has been divided into millet at 100°C for 20 minutes; then take it out after sterilizing at 115°C for 40 minutes, then shake the bottom of the shaker flask to disperse the millet evenly;

[0042] (5) After each shake flask was aired to room temperature, the spore concentration was 1.2×10 8 0.5ml ...

Embodiment 2

[0046] In this embodiment, the process of culturing and preparing rice spores is described by taking the water increase amount of millet reaching 25% as an example, including the following steps:

[0047] (1) Weigh 200g (W1) of millet, 80ml of water, and 2g of corn steep liquor, mix the corn steep liquor and water evenly and pour into a pot to heat, then pour the millet into it and stir-fry until the weight of the millet reaches 260g and take out ;

[0048] (2) Steam the fried millet at 105°C for 15 minutes, and then rub it up;

[0049] (3) after the steamed millet is dried to 250g (W2), the millet is divided into shake bottles, 25g / bottle;

[0050] (4) steam the shake flask that has been divided into millet at 95°C for 25 minutes; then take it out after sterilizing at 121°C for 30 minutes, then shake the bottom of the shaker flask to disperse the millet evenly;

[0051] (5) After each shake flask was aired to room temperature, the spore concentration was 2.6×10 8 0.5 ml of...

Embodiment 3

[0055]In this embodiment, the process of culturing and preparing rice spores is described by taking the water increase amount of millet reaching 50% as an example, including the following steps:

[0056] (1) Weigh 200g (W1) of millet, 120ml of water, and 4g of corn steep liquor, mix the corn steep liquor and water evenly and pour into a pot to heat, then pour the millet into it and stir-fry until the weight of the millet reaches 310g and take out ;

[0057] (2) Steam the fried millet at 100°C for 20 minutes, then rub it up;

[0058] (3) after the steamed millet is dried to 300g (W2), the millet is divided into shake bottles, 20g / bottle;

[0059] (4) Steam the shake flask that has been divided into millet at 90°C for 30 minutes; then take out after sterilizing at 123°C for 25 minutes, then shake the bottom of the shaker flask to disperse the millet evenly;

[0060] (5) After each shake flask was aired to room temperature, the spore concentration was 1.44×10 8 0.2 ml of Monas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap