Spinning process for pure high-count combed camel hair woven yarn

A camel hair and combing technology is applied in the field of combing and spinning of special animal fibers, which can solve the problems of low moisture regain, low product added value, waste of high-grade raw materials, etc. of camel hair, and achieve the effect of good strength and elongation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

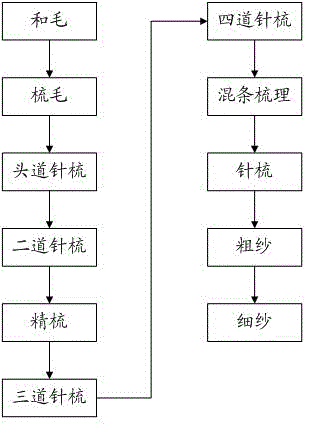

Image

Examples

Embodiment 1

[0038]The spinning process of 120 counts of combed camel hair pure woven yarns includes the following steps: (1) Blending wool: adding 0.3% of the ratio of crude oil to water, about 0.3% of antistatic agent, and then storing for 12 hours, fully Absorption, control moisture regain 18%; (2) Combing: feed roller speed 3 rpm, cylinder speed 120 rpm, doffer speed 10 rpm, transfer roller speed 160 rpm, cylinder and work roll The four-point gauge from front to back is 0.13mm, 0.15mm, 0.16mm and 0.18mm, and the basis weight of raw sliver is 8 / g m; And control the moisture regain and anti-static treatment, specifically: the gauge is 20mm, the draft is 5 times, the weight of the strip is 20 g / m, the speed is 25m / min, and the weight of the crude oil is 0.3% of the total weight of the camel hair. The weight of the antistatic agent is 0.3% of the total weight of the camel hair; (4) Two needle combs: adopt small draft, small gauge, light weight, small tension and medium pressure technology ...

Embodiment 2

[0040] The spinning process of 100 counts of combed camel hair pure woven yarns includes the following steps: (1) Blending wool: adding 0.35% of the ratio of crude oil to water, about 0.35% of antistatic agent, and then storing for 12 hours, fully Absorption, control moisture regain 19%; (2) Combing: feed roller speed 3 rpm, cylinder speed 120 rpm, doffer speed 10 rpm, transfer roll speed 160 rpm, cylinder and work roll The four-point gauge from front to back is 0.13mm, 0.15mm, 0.16mm and 0.18mm, and the basis weight of raw sliver is 8 / g m; And control the moisture regain and anti-static treatment, specifically: the gauge is 21mm, the draft is 5.5 times, the weight of the lower machine bar is 20 g / m, the speed is 28m / min, and the weight of the added crude oil is 0.35% of the total weight of the camel hair. The weight of the antistatic agent is 0.35% of the total weight of the camel hair; (4) Two needle combs: adopt small draft, small gauge, light weight, small tension and medi...

Embodiment 3

[0042] The spinning process of 80 counts of combed camel hair pure spinning machine weaving yarns includes the following steps: (1) Blending wool: adding 0.4% of the ratio of crude oil to water, about 0.4% of antistatic agent, and then storing for 12 hours, fully Absorption, control the moisture regain rate to 20%; (2) Carding: feed roller speed 3 rpm, cylinder speed 120 rpm, doffer speed 10 rpm, transfer roller speed 160 rpm, cylinder and work roll The four-point gauge from front to back is 0.13mm, 0.15mm, 0.16mm and 0.18mm, and the basis weight of raw sliver is 8 / g m; And control the moisture regain and anti-static treatment, specifically: the gauge is 22mm, the draft is 6 times, the weight of the strip is 20 g / m, the speed is 30m / min, and the weight of the crude oil is 0.4% of the total weight of the camel hair. The weight of the antistatic agent is 0.4% of the total weight of the camel hair; (4) Two needle combs: adopt small draft, small gauge, light quantitative, small te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com