High-elasticity sticky weft knitted fabric, preparation method and application thereof

A woven fabric and hand weft technology, applied in the textile field, can solve the problems of explosive yarn, weaving difficulties, low production efficiency, etc., and achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

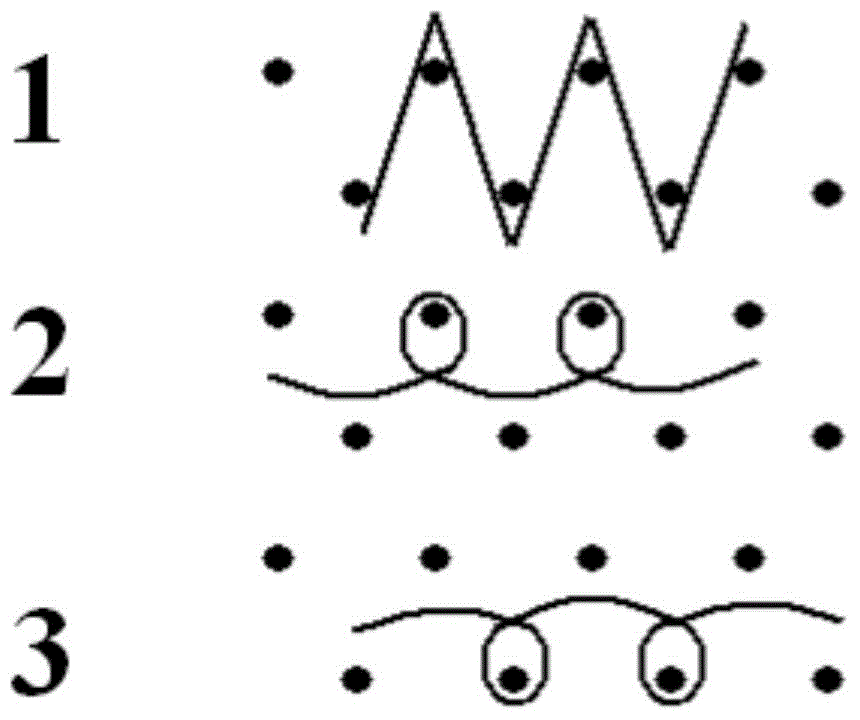

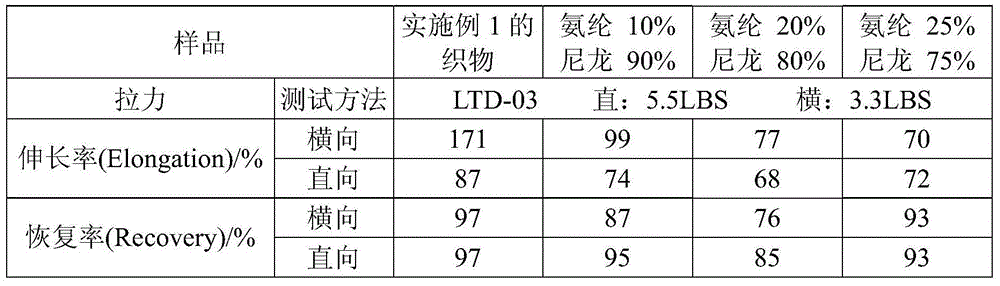

[0031] This embodiment provides a kind of high-elastic sticky weft knitted fabric and its preparation method. The weaving process of the preparation method is as follows: figure 1 As shown, the preparation method specifically includes the following steps:

[0032] Weave 20D H-550SPANDEX low-temperature spandex yarn and 30D / 34F NYLON6 nylon filament through "28G 34" double-sided large circular machine (SANTEC) by weft knitting method:

[0033] Knit 20D H-550SPANDEX low-temperature spandex yarn with needles (tuck) on the knitting needles of the upper dial, and at the same time knit with needles (tuck) on the knitting needles of the lower dial to form a double-sided structure with needles 1, with needles Double sided tissue 1 as figure 1 The needle-containing double-sided tissue shown in 1;

[0034] Then 20D H-550SPANDEX low-temperature spandex yarn is woven on the knitting needles of the upper dial and the knitting needles of the lower dial are not knitted to form the upper un...

Embodiment 2

[0045] This embodiment provides a high elastic sticky weft knitted fabric and a preparation method thereof, the preparation method specifically comprising the following steps:

[0046] Weave 70D SPANDEX low-temperature spandex yarn and 50D / 34F NYLON6 nylon filament through "28G 34" double-sided large circular machine (SANTEC) by weft knitting method:

[0047] 70D SPANDEX low-temperature spandex yarn is knit with needles (tuck) on the knitting needles of the upper dial, and at the same time knit with needles (tuck) on the knitting needles of the lower dial to form a double-sided weave with needles;

[0048] Then weave 70D SPANDEX low-temperature spandex yarn on the knitting needle of the upper dial and keep the knitting needle of the lower dial from knitting to form the upper unilateral weave;

[0049] Then knit 70D SPANDEX low-temperature spandex yarn and 50D / 34F NYLON6 nylon filament at the same time on the lower dial needle (knitting) and keep the upper dial needle from knit...

Embodiment 3

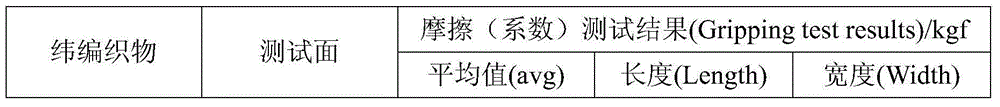

[0053] The high elastic sticky hand weft knitted fabrics prepared in Examples 1 and 2 were tested for friction performance with the fabrics prepared by using different raw materials and different weaving methods, and the test results are shown in Table 2. Wherein, polyester+spandex and cotton+spandex are the corresponding fabrics obtained by weaving through conventional weft knitting methods in this field.

[0054] Table 2

[0055]

[0056]

[0057] As can be seen from the data in Table 2, the friction coefficient of the spandex surface of the fabrics made in Example 1 and Example 2 is significantly better than the test results of other components, indicating that the fabrics made by the preparation method of the present invention have sticky and non-slip properties. performance and good adhesion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com