A precision intelligent fabric, ribbon, zipper drying and setting processing machine

A technology of drying, setting and processing machine, which is applied in the field of dyeing machinery, can solve the problems of uneven stress, uneven temperature, and uneven stress of webbing, and achieve the effects of reducing personnel and equipment investment, high safety performance, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments, but the implementation and protection of the present invention are not limited thereto. If there are any parts not specifically described in detail below, those skilled in the art can refer to the prior art.

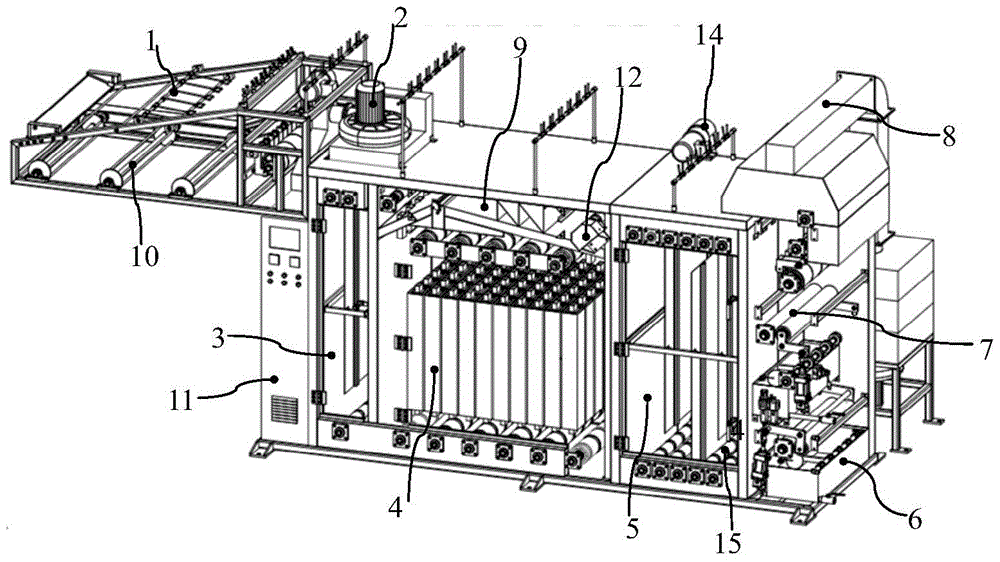

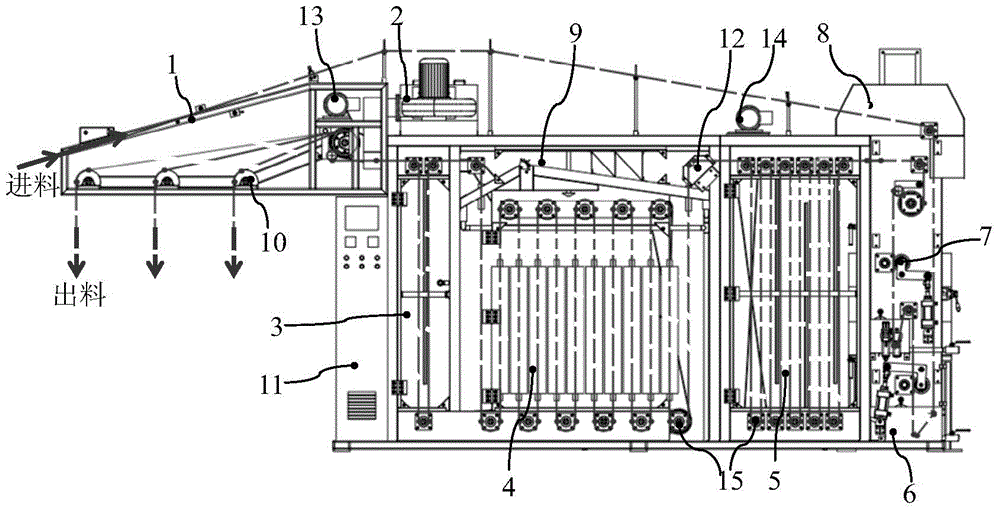

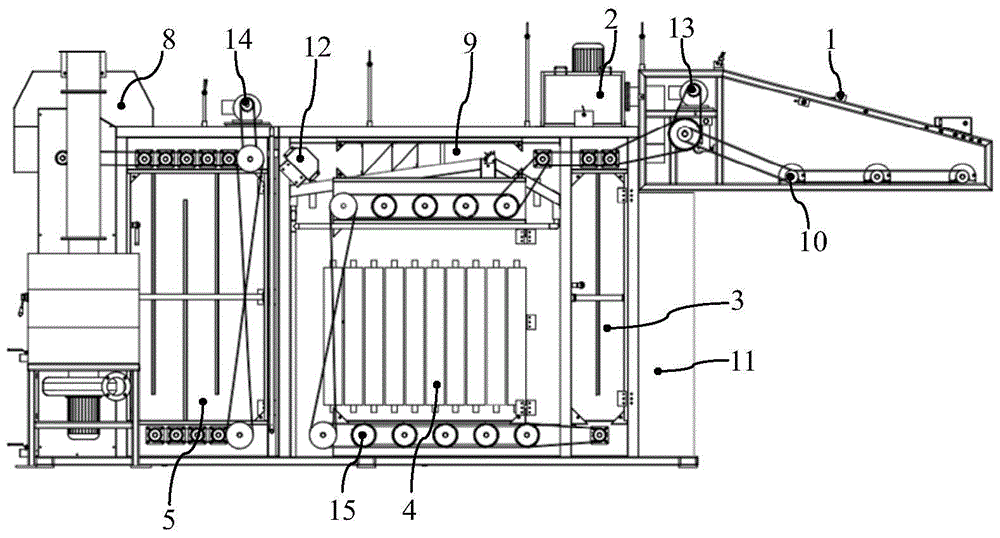

[0027] Such as Figure 1 ~ Figure 3 As shown, a precision intelligent fabric, ribbon, zipper drying and shaping processing machine, which includes a cloth guide unit 1, a fan and a nozzle 2, a cooling box 3, an electromagnetic induction heating tube 4, a preheating box 5, an auxiliary agent tank 6, and Agent content adjustment unit 7, exhaust gas collection and purification system 8, waste heat collection pipe 9, cloth receiving unit 10, central control system 11, tension sensor 12, front servo motor or frequency conversion control motor 13, rear servo motor or frequency conversion control motor 14, Drive shaft 15, etc.; the fabric to be processed, webbing, slide fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com